2. Add the required amount of cement into th

drum.

3. Add the required amount of sand into th

drum.

4. Pour the required amount of water into th

drum.

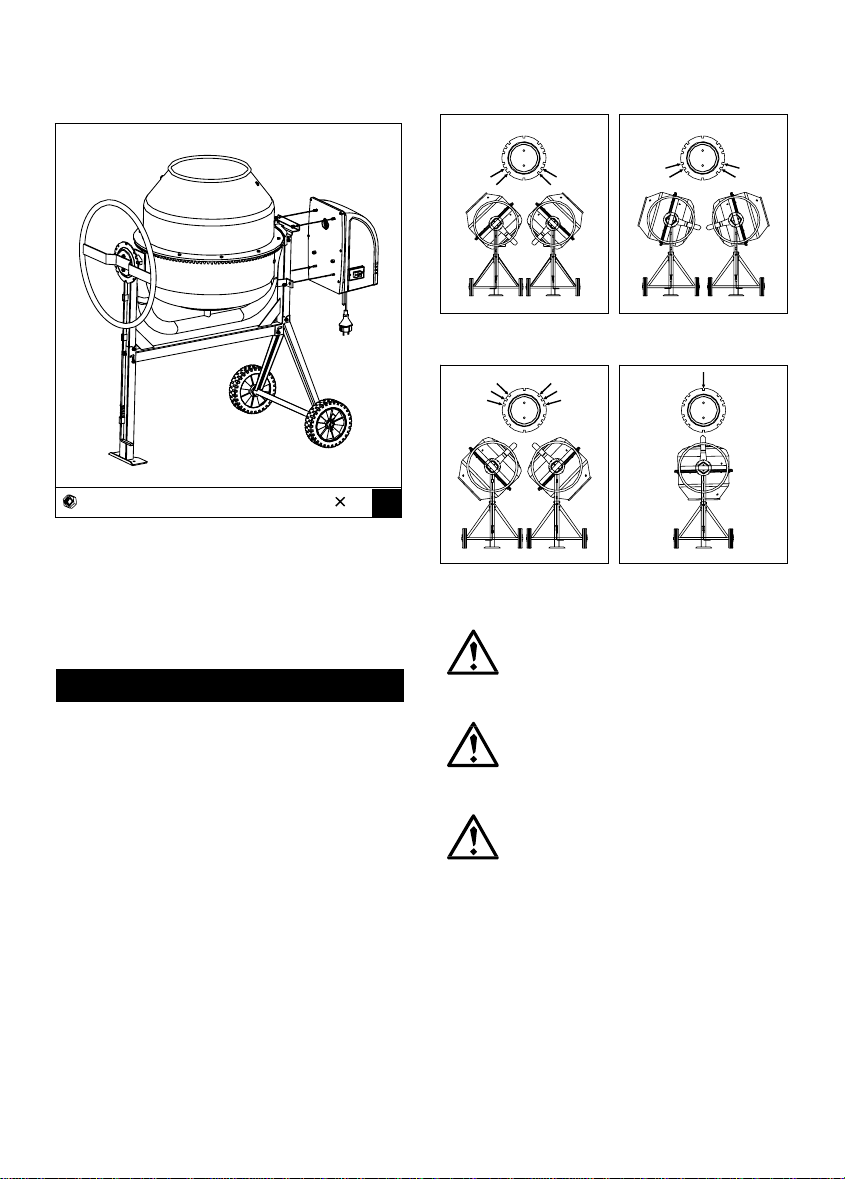

EMPTYING

Do not turn mixer off while ful

of load. Emptying the drum wit

drum rotating.

CLEANING

Never put hands inside the dru

with drum rotating.

Thoroughly clean the mixer at the end o

each day’s operation. Keep your mixe

clean. The slightest trace of material left i

the drum will harden and attract more eac

time you use it until the machine i

useless. Dried cement should be scrape

out of the drum. Do not throw bricks into mixe

drum to clean it out. Do not beat on th

drum with a shovel, a hammer or other tool

to break up accumulations of dried cemen

mix, as damage to the mixer may result. Th

drum may be scoured for approximate

minutes, using 1” gravel and wate

mixture. Then discharge the gravel/wate

mixture and hose down the drum assembl

inside and out. The IP44 protection clas

construction of the concrete mixer enable

you to hose down the drum assembly safely.

MAINTENANCE INSTRUCTIONS

Ensure the extension cord

is always unplugged before the

motor cover is removed.

The wiring diagram and parts

schematic in this manual are as

reference tools only. Neither the

manufacturer nor distributor

makes any representation or

warranty of any kind to the buyer

that he or she is qualified

to make any repairs to the product

or that he or she is qualified to

replace any parts of the product.

Only qualified technicians

should repair the mixer. Any

maintenance and repairs carried

out, to any of the electric

components must be undertaken by

a qualified electrician.

Parts in a circle should only be fitted

by a qualified electrician.

WIRING DIAGRAM

Do n

t po

r

r spra

water directl

over the motor cover, especiall

the openings in it.

Wipe off an

externa

materia

on

the motor cover. Do not use petrol

turpentine, lacquer or paint thinner

products. The use of chemical

products or solvents may affect

the properties of the cover which

wa s made of high density

polyethyiene.

10

dry cleaning fluids or similar