Contents

SAFETY INFORMATION ...................................................................................................................1

1.0 INTRODUCTION .........................................................................................................................1

1.1 SAFETY NOTICE.........................................................................................................................2

1.2 BALANCERAPPLICATION..........................................................................................................2

1.3 BFH 1000 SPECIFICATIONS .....................................................................................................2

1.4 FEATURES ...................................................................................................................................3

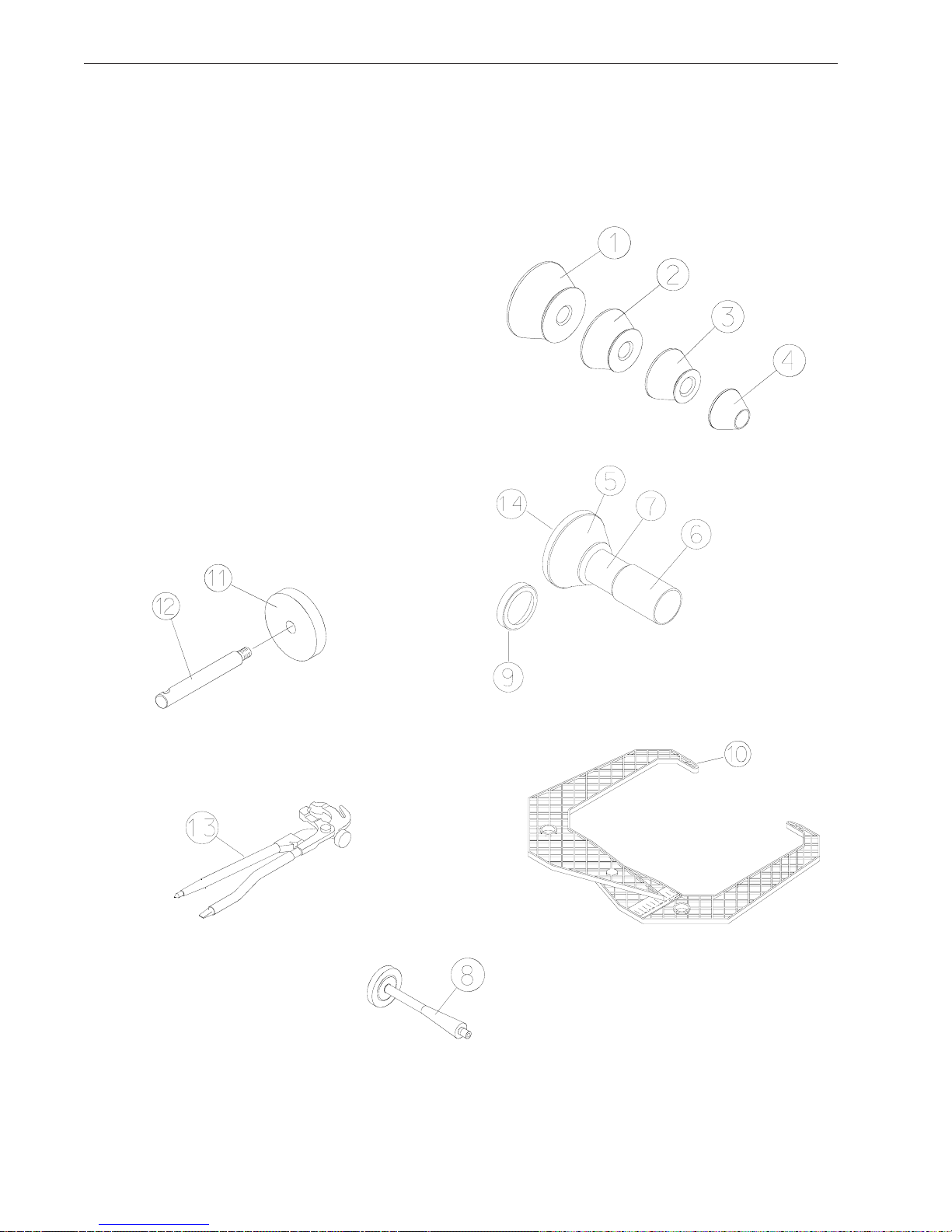

1.5 STANDARD ACCESSORIES .......................................................................................................4

1.6 OPTIONAL ACCESSORIES ........................................................................................................5

1.6 PRE-INSTALLATION CONSIDERATIONS .................................................................................5

1.7 DIMENSIONS OF THE MACHINE ..............................................................................................5

1.8 INSTALLATION AREA REQUIREMENTS ...................................................................................6

1.9 INSTALLATION PRECAUTIONS ................................................................................................6

2.1 ELECTRIC INSTALLATION.........................................................................................................7

2.2 SETUP..........................................................................................................................................7

2.2.2 CUSTOMIZING OPTIMA FEATURES .....................................................................................9

3.0 Physical Layout..........................................................................................................................9

3.1 The Display Screen ....................................................................................................................9

3.2 Menu Keys.................................................................................................................................10

3.2.2 MAIN MENU FUNCTIONS ....................................................................................................11

3.2.3 BALANCING ...........................................................................................................................11

3.2.8 FUNCTION (SETUP) .............................................................................................................13

4.0 Help information .......................................................................................................................14

5.0 POWER CLAMP.........................................................................................................................15

6.0 OPERATION OF THE BALANCER ...........................................................................................16

6.1 CHECK LIST - INSPECTION...................................................................................................16

6.2 BALANCE SCREEN DESCRIPTION .......................................................................................17

6.2.1 WHEEL MOUNTING..............................................................................................................18

6.2.2 STANDARD WHEELS (BACK CONE MOUNT) ...................................................................18

6.2.3 CENTERING LIGHT-TRUCK WHEELS ................................................................................18

6.3 SCAN MODE SELECTION........................................................................................................19

6.4 SPINNING THE WHEEL............................................................................................................20

6.5 SELECTING THE WEIGHT PLACEMENT..............................................................................20

6.6 CORRECTION OF THE IMBALANCE......................................................................................21

6.6 PROCEDURE WHEN SCANNER FAILS TO ACQUIRE A VALID PROFILE ............................21

6.7 VERIFICATION OF THE RESULTS ..........................................................................................21

6.8 VIBRATION PROBLEMS .........................................................................................................22

7.0 SPOKE BALANCING MODE.....................................................................................................22

8.0 BFH 1000 Procedures ............................................................................................................23

8.2 Begin Diagnostic Run .............................................................................................................23

8.2 Profiling the wheel....................................................................................................................23

8.3 BFH 1000 Geometric Matching..............................................................................................25

8.4 Bare Rim Diagnosis .................................................................................................................27

9.0 OptiLine, Balancing a Set of Wheels ....................................................................................28

9.1 OptiLine Customer Calibration ..............................................................................................31

9.0 USER CALIBRATION ................................................................................................................33

10.0 EXPLANATION OF PROGRAM CODES ................................................................................34

11.0 MAINTENANCE........................................................................................................................36

12.0 TROUBLE SHOOTING ...........................................................................................................36