© 2021 John Blue Co.6

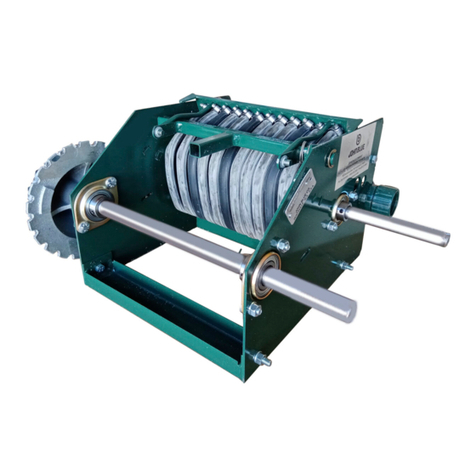

3.) Hydraulic Drive with Manifold Configuration (P/N: CS-150-HYM):

Installation:

This configuration is designed to drive the pump via a hydraulic

motor with a manifold.

** Note that any plumbing must be supported so that its weight

does not hang off the pump, this will void the warranty.

Storage:

After use, flush the pump with a solution that will neutralize the

fluid you have been pumping, and then drain, then fill the pump

with RV antifreeze for storage.

Maintenance:

Inspect the seal reservoir fluid level using the sight window, the

fluid level should be above the middle of the window. If the fluid

is dirty, drain the pump by vacuum or turning upside down, then

replace with 50/50 premixed ethylene glycol antifreeze. If fluid is

cloudy, impeller side seal may be leaking.

Hydraulic Drive Specifications:

Max Hydraulic Flow : 25 GPM*

Ideal Hydraulic Flow : 4 GPM

Max Hydraulic Pressure : 3000 PSI*

Pump Port (P) Size : SAE-10

Tank Port (T) Size : SAE-10

Gauge/Load Sense Port (M1G/LS) : SAE-4

Hydraulic line sizes should be sized appropriately to the flow capacity of the tractor / supply and rated for

3000 PSI continuous operating pressure, for flowrates from 0-4 GPM size -6 (3/8”) hose is recommended,

for flowrates from 8-15 GPM size -8 (1/2”) hose is recommended, for flowrates from 15-25 GPM size -10

(5/8”) hose is recommended, and for the M1G/LS Line size -4 (1/4”) hose is recommended.

* MAXIMUM WATER FLOW FROM THE PUMP IS ACHIEVED AT 4 GPM HYDRAULIC FLOW, HYDRAULIC

FLOW IN EXCESS OF 25 GPM OR HYDRAULIC PRESSURE IN EXCESS OF 3000 PSI CAN RESULT IN

DAMAGE TO THE HYDRAULIC MOTOR OR MANIFOLD. ALL HYDRAULIC FLOW IN EXCESS OF 4 GPM

IS BYPASSED BACK TO THE TANK AND CAN CAUSE HEAT GENERATION WITHIN THE HYDRAULIC

SYSTEM.