12-M-74 1 Rev. 2/2020

before operating

WARNING: USE OF THIS PRODUCT FOR ANY PURPOSES OTHER THAN ITS ORIGINAL INTENT, ABUSE OF THE PRODUCT, AND/OR MODIFICATION TO THE ORIGINAL

PRODUCT IS STRICTLY PROHIBITED BY JOHN BLUE COMPANY. JOHN BLUE COMPANY RESERVES THE RIGHT TO DENY WARRANTY OR LIABILITY CLAIMS IN ANY/ALL

SITUATIONS INVOLVING MISUSE, ABUSE OR MODIFICATION.

THE ORIGINAL INTENT OF THIS PRODUCT DOES NOT INCLUDE USE WHERE THE MAXIMUM ALLOWED PRESSURE OR TEMPERATURE IS EXCEEDED, AND IT

DOES NOT INCLUDE APPLICATIONS UTILIZING FLUIDS THAT ARE NOT COMPATIBLE WITH THE PRODUCT’S COMPONENT MATERIALS. DO NOT USE THIS PRODUCT WITH

FLAMMABLE OR COMBUSTIBLE FLUIDS SUCH AS GASOLINE, KEROSENE, DIESEL, ETC... FAILURE TO FOLLOW THIS NOTICE MAY RESULT IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE AND WILL VOID THE PRODUCT WARRANTY. IF IN DOUBT ABOUT YOUR APPLICATION, CONTACT YOUR STOCKING DEALER OR THE JOHN BLUE

TECHNICAL STAFF AT 1-800-253-2583.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information

go to: www.P65Warnings.ca.gov.

SAFETY PRECAUTIONS: EQUIPMENT SHOULD BE OPERATED BY RESPONSIBLE PEOPLE. A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN ACCIDENT.

FILL SYSTEM WITH WATER FIRST AND CHECK FOR LEAKS – REPLACE HOSES WHEN WORN OR CRACKED.

- Max flow: 375 gpm

- Max pressure: 45 psi

- Required HP: 10 HP

- Port size: 3” FPT

- Materials: Polypropylene, Viton®O-rings,

316 stainless bolts and shaft

-Optional screw-in M300 flange adapter is P/N: 116431-01

- The standard pump is configured for gas engine use. For electric motor fitment, you must order a “-E”

pump for use on a JBC 10hp motor (see page 4).

- A shaft locating tool is used to hold the shaft during installation on the engine/motor.

This must be removed before operating the pump.

- Note that any plumbing must be supported so that its weight does not hang off of the pump – this will void

the warranty.

- If you have the -FLG version of the pump with M300 flange fittings included, the fitting threads must have

sealant applied before assembly to the pump.

- The inlet configuration of the pump may be changed by removing the 6 locknuts holding the inlet on. The

inlet check valve flap may also be removed in the high configuration.Using the pump in the high inlet

condition allows the outlet hose to drain when the pump is shut off, which is beneficial to some users.

Tighten all housing fasteners to 5 ft-lbs.

- After use flush the pump with a solution that will neutralize the fluid you have been pumping, and then

drain.Do not use water to flush acids – resulting damage not warrantied.

- The seal reservoir may be inspected by opening the fill plug. The fluid level should be approximately ½”

below the opening. If the fluid is dirty, drain by tilting the pump upside down or pull it out with a vacuum,

then replace with PREMIXED antifreeze. If the fluid is cloudy, the impeller side seal may be leaking.

Operation Manual

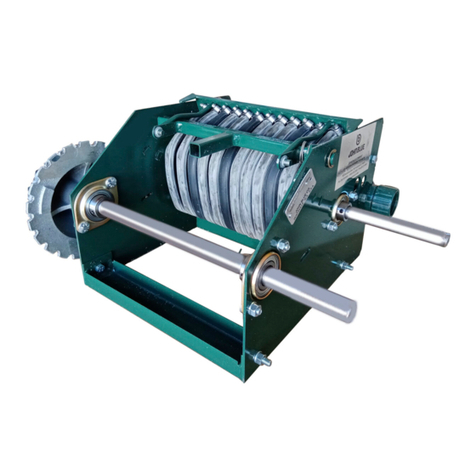

Polypropylene Self-Priming

3” Centrifugal Pump

GX-390 Honda® Engine