Sept-22

General HOBBY Laser Engraving Instructions/Flux Beamo Engraving Instructions WITHOUT the

rotary attachment

•Place the pint glass onto the laser bed and align to the zero point on the laser bed.

oFor best results, utilize a jig to help hold the pint glass level and in place during engraving.

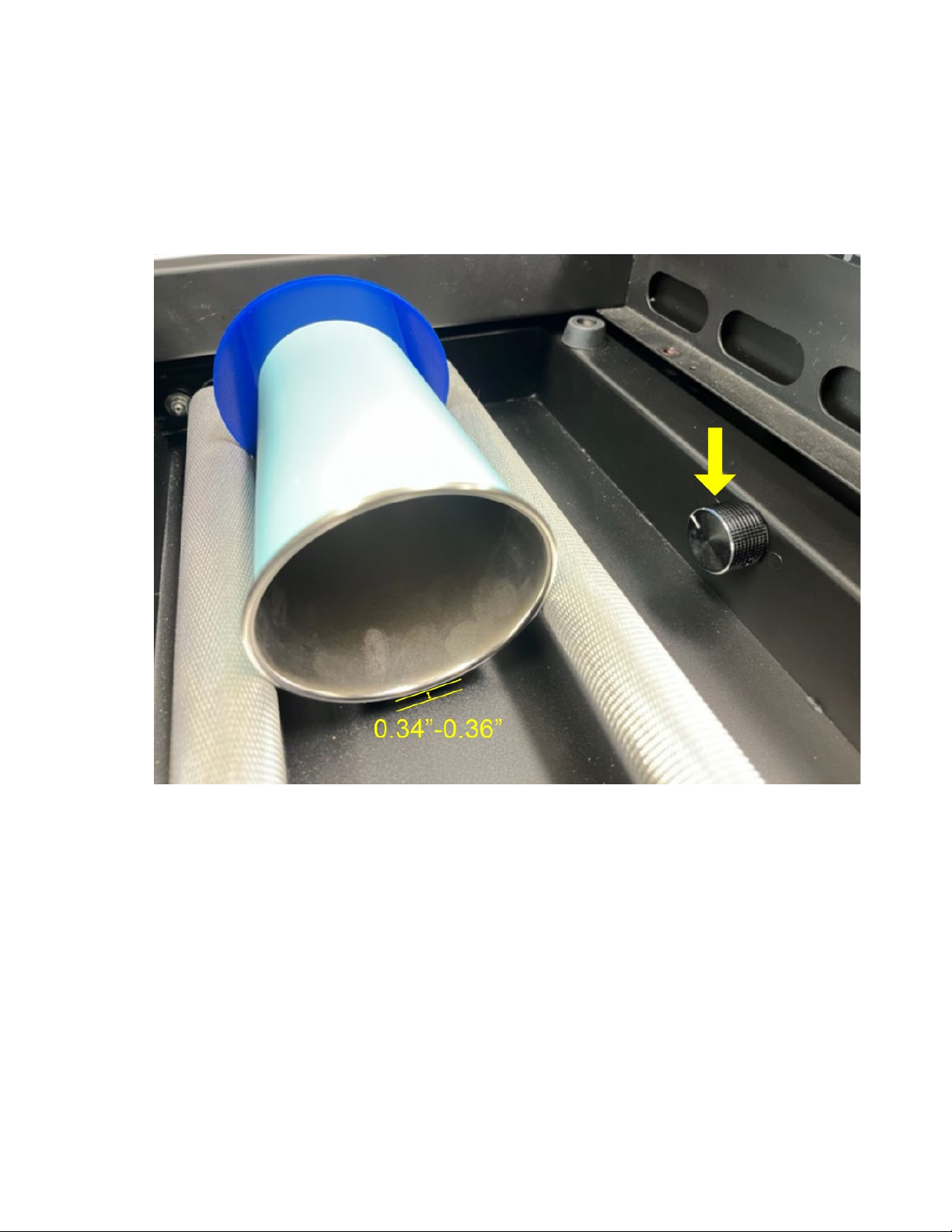

oFlux Beamo: Position the pint glass on the laser bed. Elevate the bottom of the glass so that the

side of the pint glass is parallel with the laser head.

Removing the cutting grid insert may be necessary for secure positioning of the pint glass.

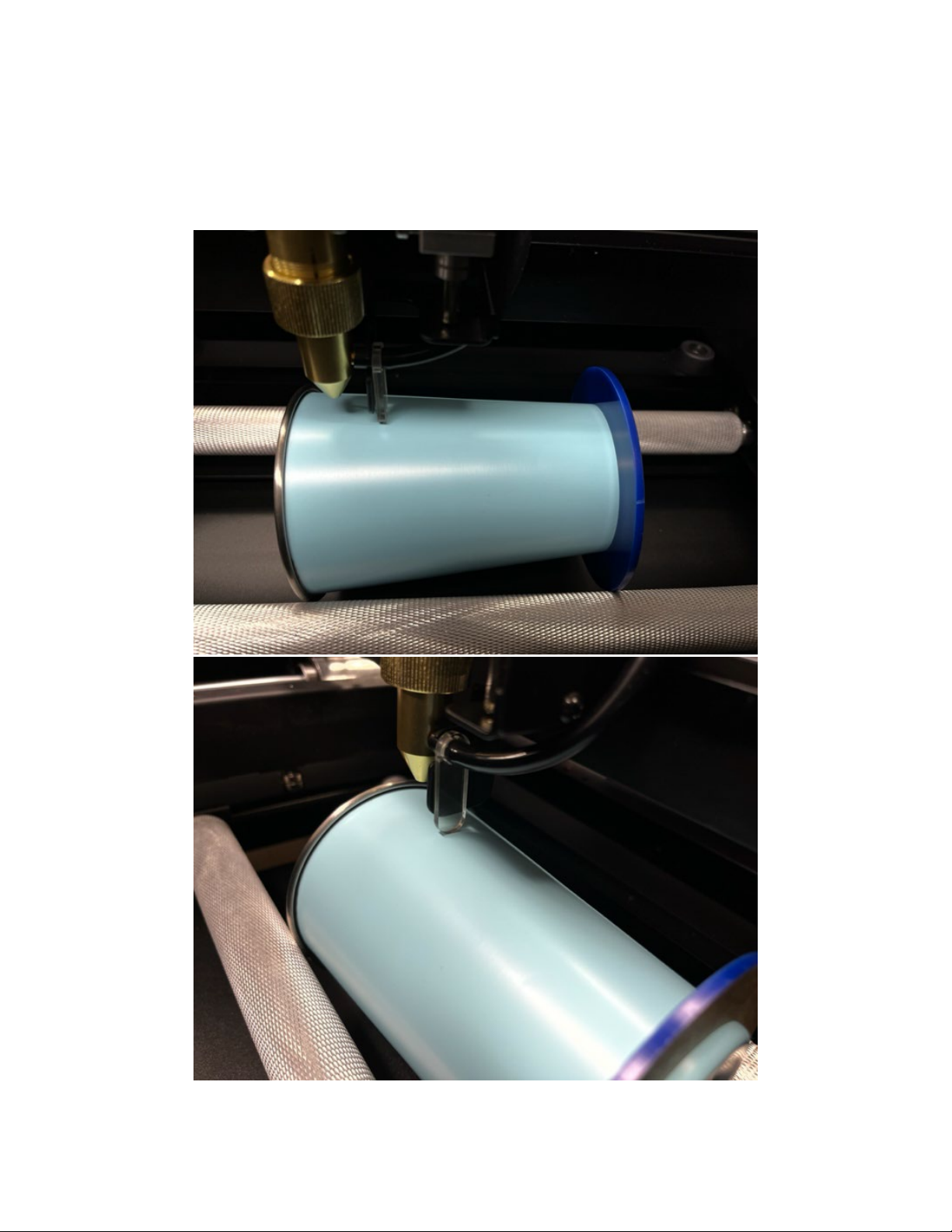

•Adjust the laser focus to the surface of the pint glass.

oWith the pint glass on its side, focus the laser just off of the highest point of the pint glass side

(usually approx. ¼” to the left or right of the highest point of the side of the pint glass).

•Once the artwork is positioned, engrave using the suggested starting settings.

oFlux Beamo: Use suggested starting settings listed in the Flux Beamo chart above.

oSettings may need adjusted depending on the laser tube wattage.

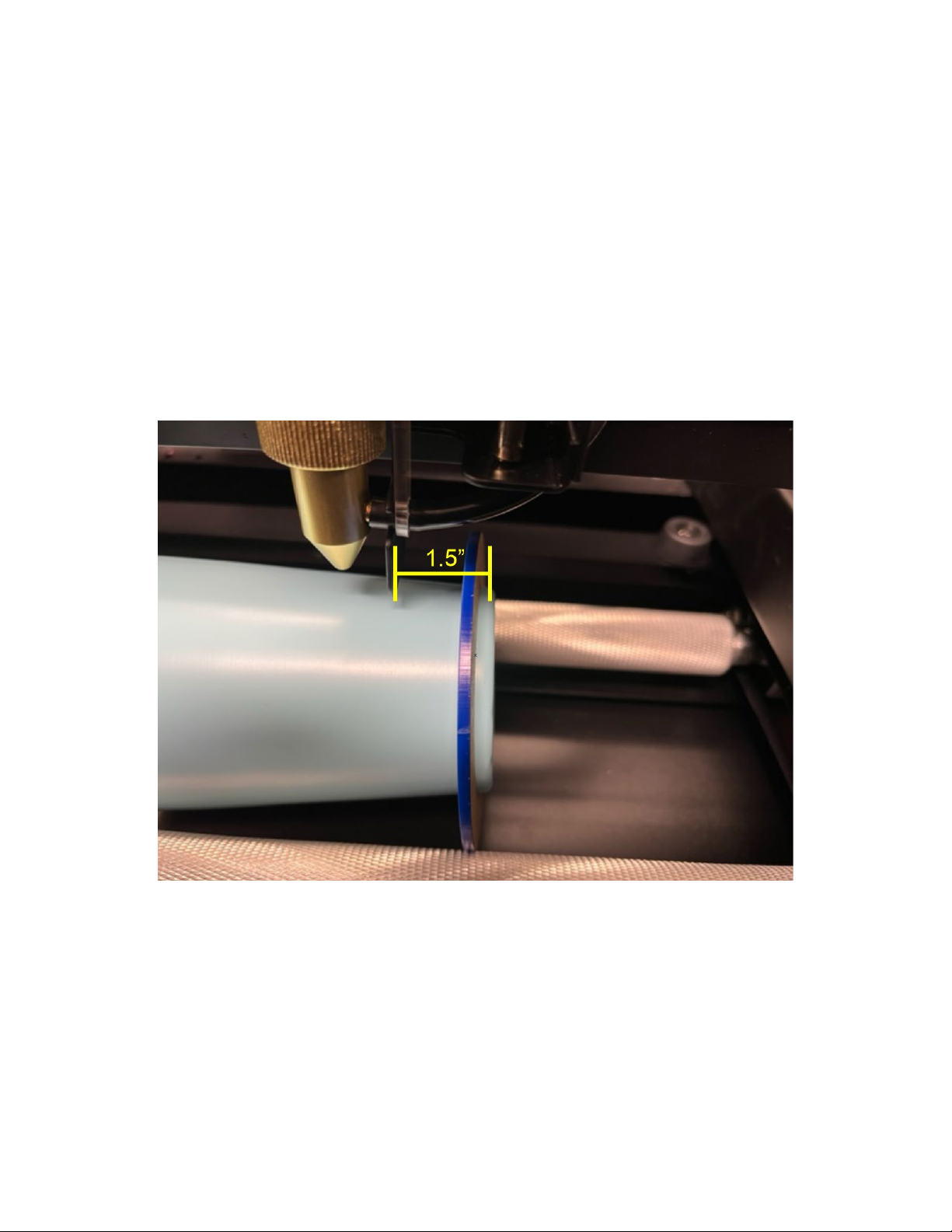

oLaser focus may need to be slightly offset from the highest point of the curvature of the

drinkware in order to accommodate more engraving width on the pint glass when the pint glass

is engraved stationary (not using a rotary attachment).

•When finished, remove the pint glass from the laser bed.

•If cleanup is needed, wipe the engraved areas with a clean cotton cloth lightly misted with isopropyl

alcohol or a kitchen degreaser cleaner.

Tips and Tricks

•To help with artwork placement, utilize the product template for this item, found on the

item's product page on jpplus.com/..

Troubleshooting

•The engraved area is charring/melting.

oLaser power setting and/or resolution may need to be decreased.

oLaser speed setting may need to be increased.

•The engraved area is very light/the color coating is not engraving away completely.

oLaser power setting and/or resolution may need to be increased.

oLaser speed setting may need to be decreased.

oThe laser focus may need to be adjusted.

oThe laser focus may need to be set to just off of the highest point of the side curvature of the pint

glass to accommodate more engraving area on the side of the glass.

oThe laser beam alignment may need to be adjusted.

oThe laser tube may be degrading and need to be replaced.