3

Contents

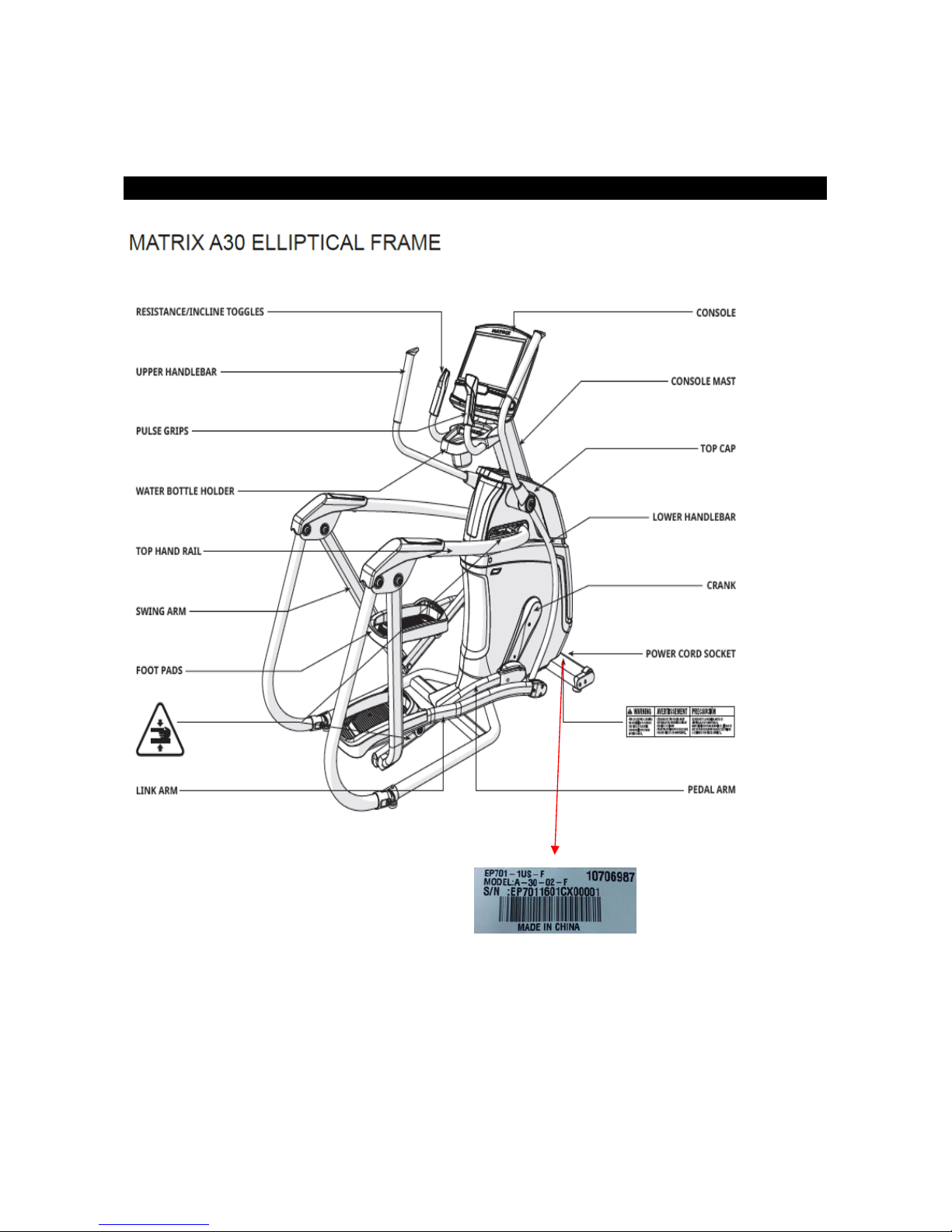

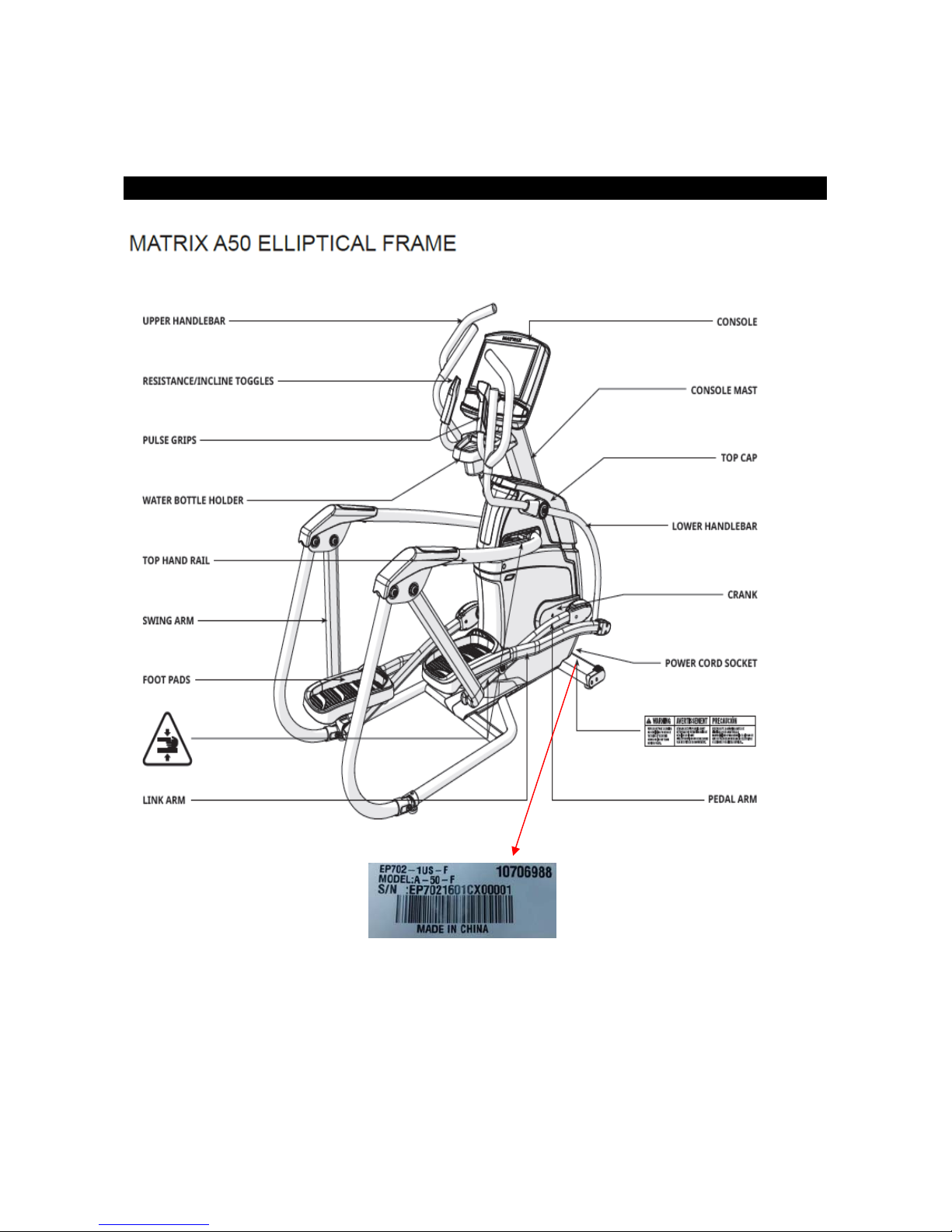

CHAPTER 1: SERIAL NUMBER LOCATION...................................................................................................5

CHAPTER 2: CONSOLE BROWSE..................................................................................................................8

CHAPTER 3: TROUBLESHOOTING

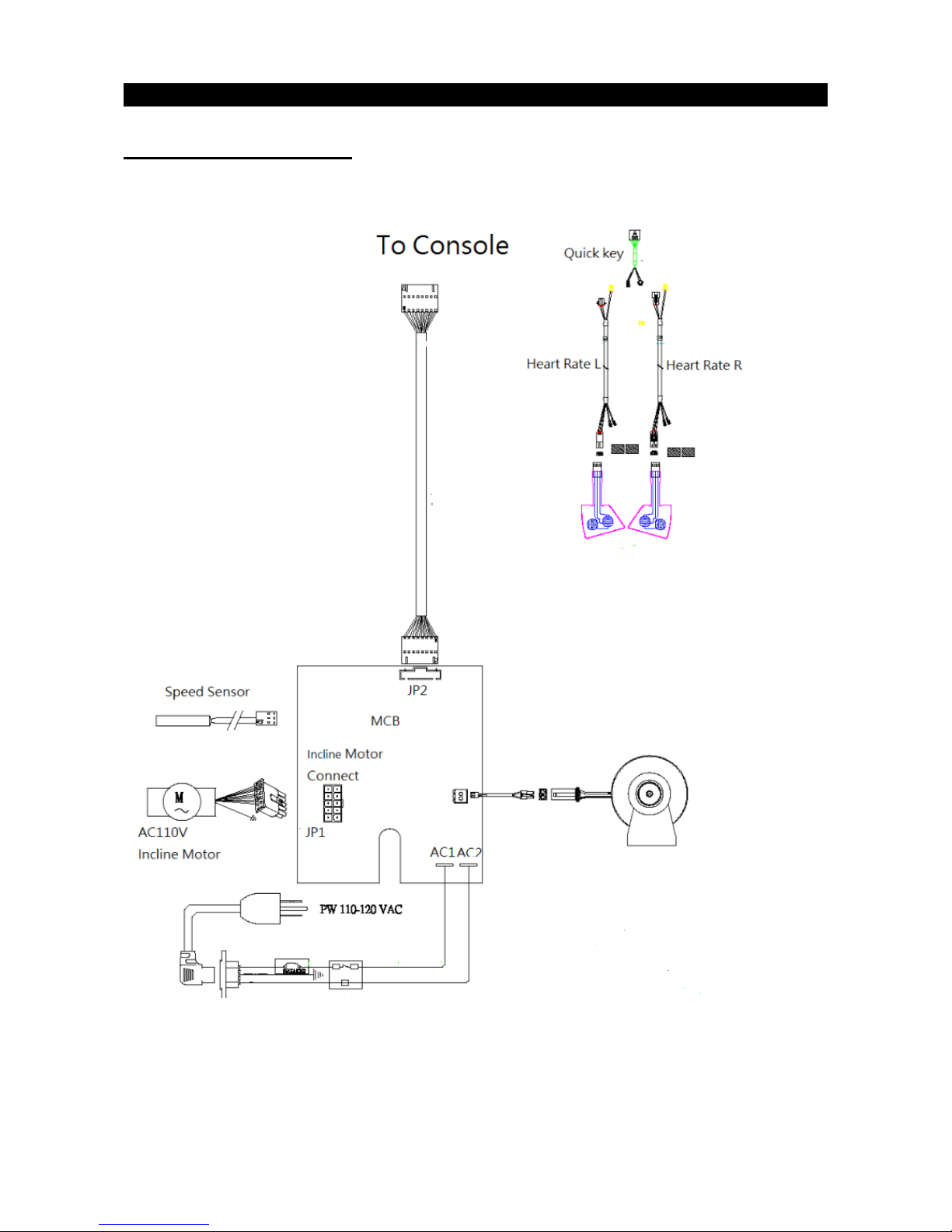

3.1 Electrical Diagram..................................................................................................................................9

3.2 MCB Connections................................................................................................................................12

3.3 Trouble Shooting..................................................................................................................................14

3.3.1 Console Does Not Light Up.....................................................................................................14

3.3.2 No Console Response.............................................................................................................15

3.3.3 System Will Not Boot...............................................................................................................15

3.3.4 No Display on the Console or the Display is Dim....................................................................15

3.3.5 No RMP Display.......................................................................................................................16

3.3.6 No Resistance Or Incorrect Resistance...................................................................................17

3.3.7 Heart Rate Function Issues.....................................................................................................20

3.3.8 Pedals Slipping........................................................................................................................21

3.3.9 Knocking and Creaking Noise..................................................................................................22

3.3.10 Handlebar Keypad Failure........................................................................................................23

CHAPTER 4: PART REPLACEMENT GUIDE

4.1 Console Replacement .......................................................................................................................... 24

4.2 Heart Rate Grip Replacement .............................................................................................................. 25

4.3 Upper Handle Bar Replacement .......................................................................................................... 26

4.4 Lower Handle Bar Replacement .......................................................................................................... 27

4.5 Pedal Arm Replacement ...................................................................................................................... 28

4.6 Console Mast Covers Replacement………………………………………………………………………...29

4.7 Console Mast Replacement ................................................................................................................. 30

4.8 Link Arm Replacement ......................................................................................................................... 31

4.9 Crank Arm Replacement ...................................................................................................................... 32