06 07

E01 Low voltage

supply (below

130V)

The supply voltage is too low.

This is generally a fault from

the local municipality and can

damage your pump.

Turn the pump o and disconnect it from the power

source. Proceed to contact a registered electrician to

inspect your power supply.

E02 High voltage

from supply

(above 280V)

The supply voltage is too high.

This is generally a fault from

the local municipality and can

damage your pump.

Turn the pump o and disconnect it from the power

source. Proceed to contact a registered electrician to

inspect your power supply.

E03 Pressure

transducer

disconnected/

faulty

Caused by a loose cable or

damaged pressure transducer.

• Check the transducer cable to see if it is damaged or

unplugged.

• If within the 12 month warranty period and the cable

is intact, return the unit to the supplier you purchased

it from, otherwise contact JoJo for further assistance.

E04 Motor

temperatures

exceeding

operating

limits

The pump is overheating.

This is generally due to poor

ventilation caused by installing

the motor fan end closer than

100mm from the nearest vertical

surface e.g. a wall or covering.

• Ensure that the motor is installed with sucient

spacing (min. 100mm) between a surface and the

motor fan to allow for sucient cooling.

• Ensure the motor is has sucient ventilation.

E08 Locked rotor Caused by objects such as

stones, plant matter, string,

sand, or mineral build-up

entering the system from the

supply side and lodging in the

pump casing, thus preventing

the impeller from rotating.

• Remove the suction and discharge piping and inspect

the inlet and outlet for any visible obstruction/s.

Remove the obstruction/s if visible.

• If within the 12 month warranty period and the error

code continues to display, return the unit to the

supplier you purchased it from, otherwise contact

JoJo for further assistance.

E09 Variable

speed drive

PC board fault

condition

Caused by power spikes, and

under voltage or over voltage that

damage the PC board. Continued

faults of this nature indicate

power grid instability and can

lead to permanent damage of

the electronic circuitry.

• IMPORTANT: this is not covered by the warranty.

• Please contact JoJo for further assistance. Even

though this is not covered by the warranty, we will

assess the pump to determine the extent of the

damage and advise whether a repair is possible.

E05, EO6, EO7, EO10 & EO11 -Not in use

If an error code appears on the screen, please refer to the below guide for more information.

TROUBLE SHOOTING GUIDE

JOJO PUMP WARRANTY

Please read this warranty in conjunction with the South African Consumer Protection Act 68 of 2008.

01. JoJo warrants its pumps to the original end user/purchaser to be free of defective materials and workmanship

under normal use for a period of 12-months from the date of purchase from authorised retailers and distributors.

To be eligible for warranty repair or replacement, the pump must be returned to the point of purchase during

and up to the expiry date of the warranty period. Proof of date of purchase is required.

02. Liability in terms of this warranty shall be limited to repair or replacement of the pump. Liability for all and any

other losses and/or subsequent damages suered are expressly excluded.

03. This warranty does not obligate JoJo to bear any cost of removal, installation, transportation, or other charges

which may arise in connection with a warranty claim.

03. Indicator lights and fault codes:

03.1 Mode “UP”:

• The “POWER” light will be illuminated.

• The “RUN” light will illuminate when the pump is operating.

• The “RUN” light will flash when the pump is operating but unable to reach the set

pressure. This is not unusual, as the application for household supply and irrigation

supply vary vastly in flow demand.

• The “LEAK” light will illuminate in the event of a pressure leak in the discharge line.

• If an error code appears on the screen, please refer to the trouble shooting guide on

page 7.

• Press the “HAND START/CHECK” button to reset all fault codes. Press again to resume

automatic operation.

• Operating under the “UP” mode will disable the “TIMING” light and function.

03.2 Mode “TIME”:

• “TIME” retains all settings of “UP” mode, but allows for the selection of a restart time.

For example, “3H” will start the pump every 3 hours without the system demanding an

automatic start. This function is important for applications where the unit may not be

required to operate for extended periods of time e.g. a holiday home, weekend retreat, etc.

• Daily starts keep the rotating equipment in good condition and prevents damage to

bearings.

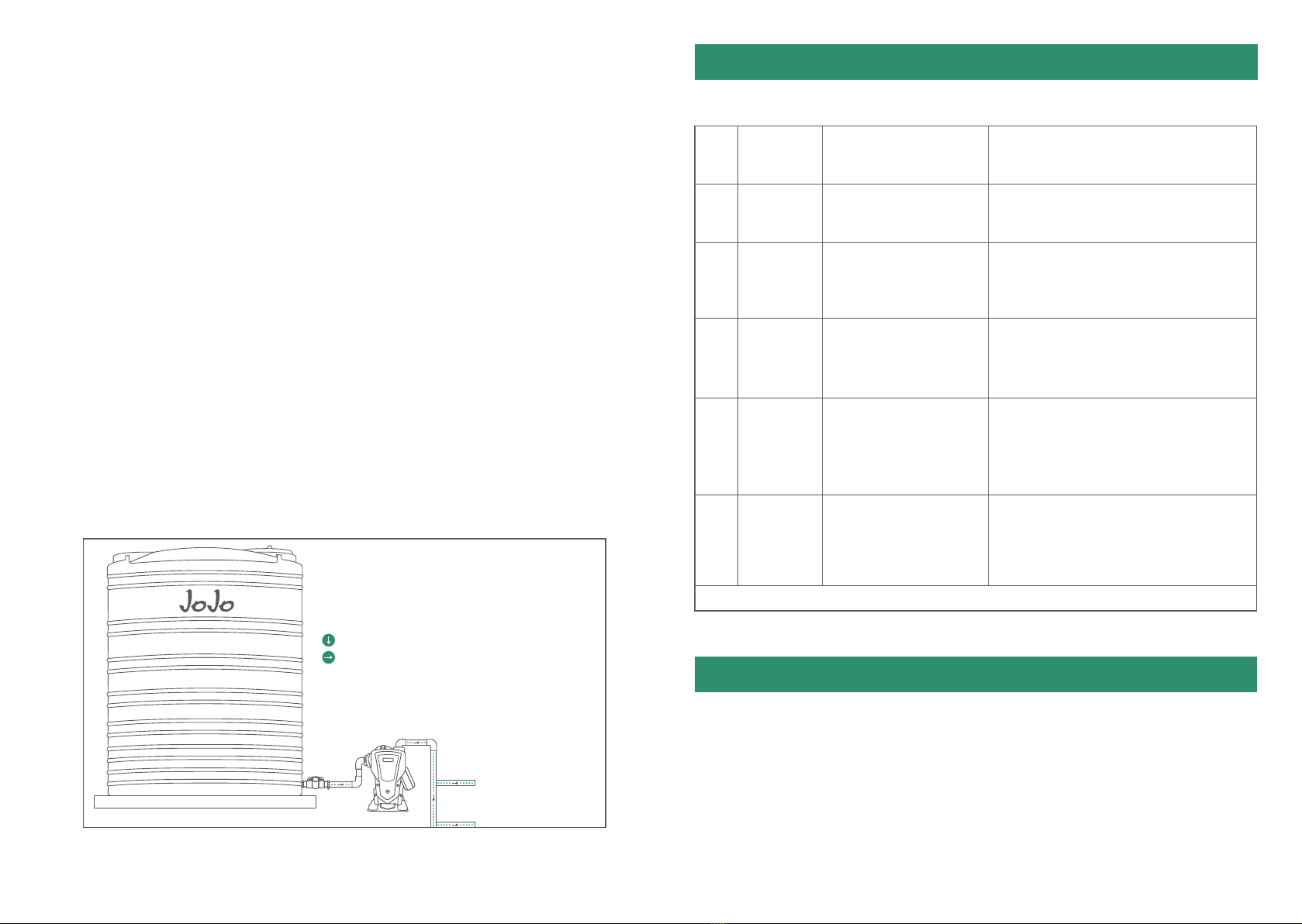

03.3 Mode “DOWN”:

• Must ONLY be selected for installations where the pump is installed on the upper

level and supplying pressure parallel or vertically down into a system. Selecting this

option will reduce the overall pressure delivered by the pump to protect against over

pressurizing lower lying systems.

Direction

of supply

vertically down

parallel to