(6) 3-Gallon Spot Extractor 3-Gallon Spot Extractor (7)

2.0 Set-Up / Prepare Unit for Use Continued

• NEVER run the vacuum only with the pump on for more than 3 minutes. Water/

solution needs to run through pump at all times to keep the pump cool while in use.

Failure to do so will void the warranty.

• Be sure to replace any lters back into the machine prior to use.

• Do not use citrus acid, buterol or harsh degreasers inside the machine.

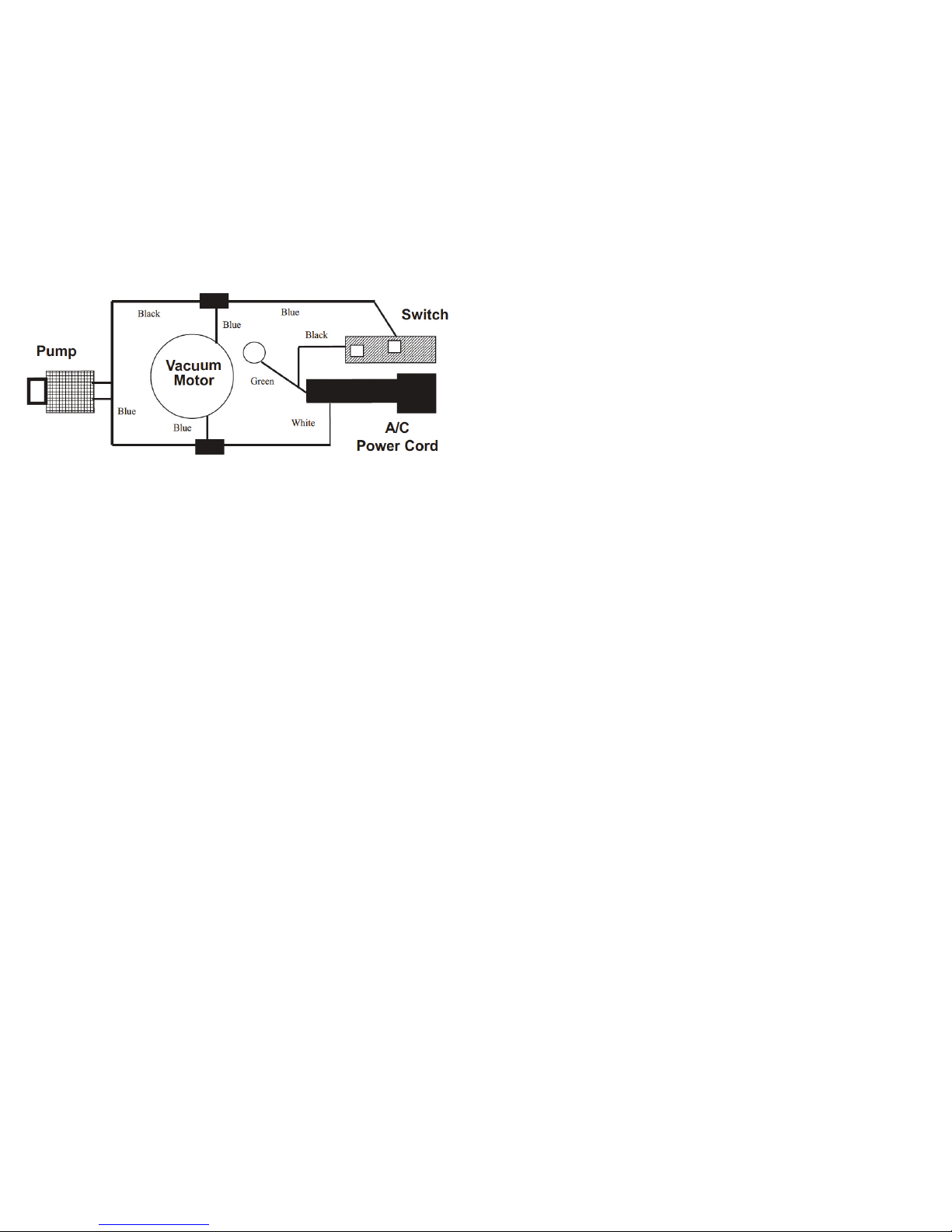

Vacuum Shut-Off

The spot extractor is designed with a vacuum restrictor to reduce

the vacuum when the recovery tank is full. When the vacuum is

restricted, the liquid will not travel up the nozzle of the hand tool.

The motor speeds up (the sound of the motor will change) and this

is your warning to dispose of recovered solution. The restrictor is a

foam oat that slides up and down the vacuum tube in the recovery

tank as shown in the photo to the right.

Following Each Use

Remove the vacuum hose from the upper body, un-clip,

rotate latch on the back of the unit and remove the upper

section of the spotter. Dispose of the used solution by

pouring the solution out of the vacuum inlet (not the

hatch cover) into the toilet or janitor’s closet sink.

3.0 Problem Solving

Never operate this spot extractor when the equipment is not performing as expected

or when any part is visibly damaged. When repair is needed, take the equipment to an

authorized service center.

Spotter will not run

• Check power connection. Move the grounded plug to an outlet that is working. Verify

that the plug is working by plugging in another electrical component such as lamp,

hair dryer or drill.

• Inspect the power cord for damage.

Loss of vacuum

• Make sure the oat is at the bottom of the unit. Open the screw cap and push the oat

down.

• Check that the hose cuff is securely attached to the front of the extractor.

Loss of solution pressure

• Verify that the pump is on. Remove jet from end of hand tool and press trigger on

wand.

• Clean the solution intake in the solution tank. Check quick-disconnect for debris.

• If pump is still not working, seek authorized repair services.

4.0 Grounding Instructions

DANGER: IMPROPER GROUNDING METHOD CAN RESULT IN A RISK OF

ELECTRIC SHOCK.

Electrical equipment must be grounded. If the machine should malfunction or breakdown,

grounding provides a path of least resistance for electrical current to reduce the risk

of electric shock. The spot extractor is equipped with a cord containing a grounding

conductor and grounding plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

If repair or replacement of the cord or plug is necessary, DO NOT connect the grounded

wire to a at bed terminal. The grounding wire is the wire with insulation and an outer

green surface, with or without yellow stripes.

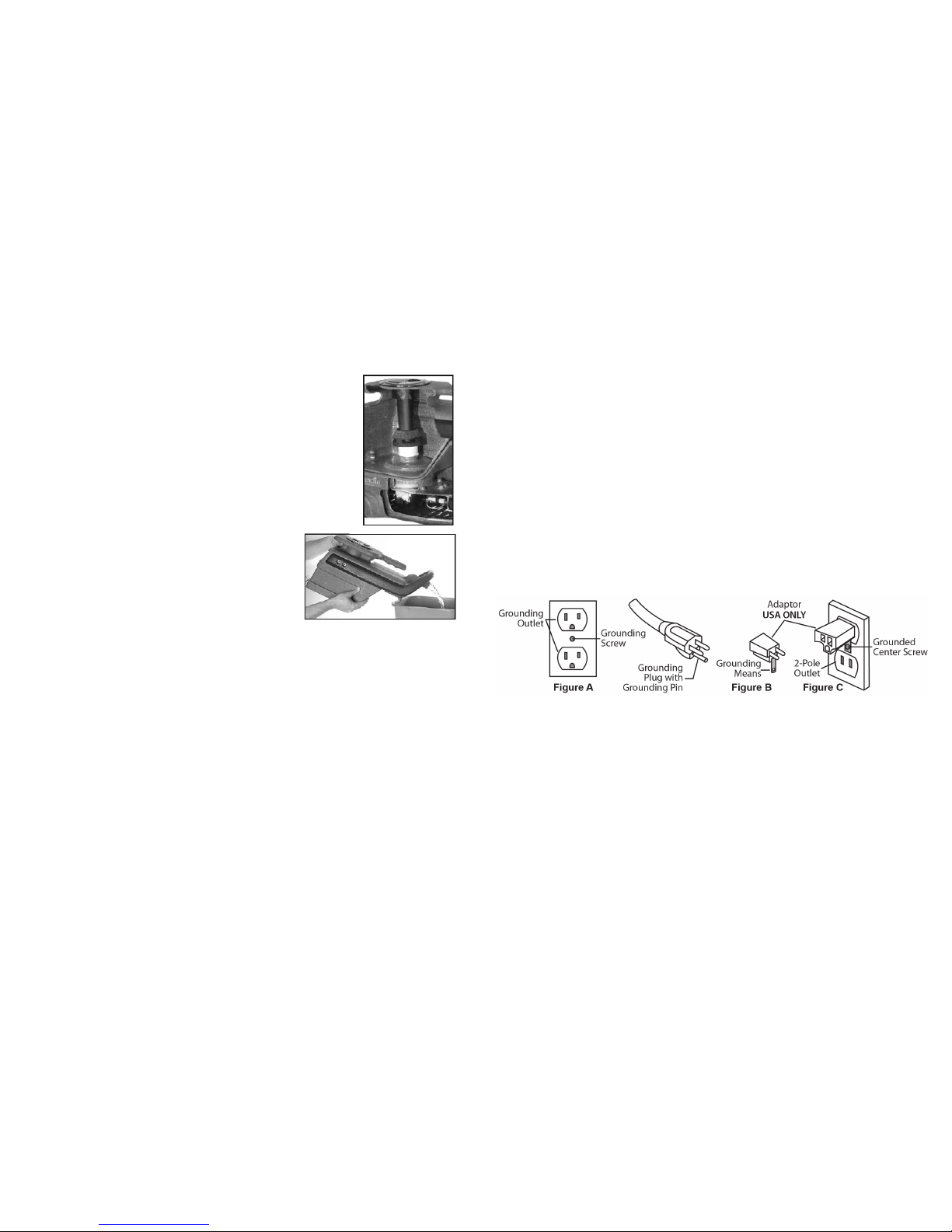

Grounding Method

The electric equipment is for use on a normal 120 volt circuit. It has a grounded plug

that ts the outlet illustrated in Figure A. If a properly grounded outlet is not available,

a temporary adapter, such as the adapter illustrated in Figure B and C, may be used to

connect the plug into a 2-pole outlet, as shown in Figure C.

The temporary adapter should be used only until a properly grounded outlet, Figure A,

can be installed by a qualied electrician. The green colored rigid ear lug or grounding

means extending from the adapter must be connected to a permanent ground, such as

a properly grounded outlet box cover. Whenever the adapter is used, it must be held in

place by its grounding means and a metal screw, as shown in Figure C.

WARNING:

Improper connection of the equipment grounding conductor can result in a risk of electric

shock. Check with a qualied electrician or service person if you are in doubt as to

whether the outlet is properly grounded. DO NOT modify the plug provided with the

equipment. If it will not t into the outlet, have a proper outlet installed by a qualied

electrician.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian

Electrical Code.