(4) 12-Gallon, 100 PSI Carpet Extractor 12-Gallon, 100 PSI Carpet Extractor (13)

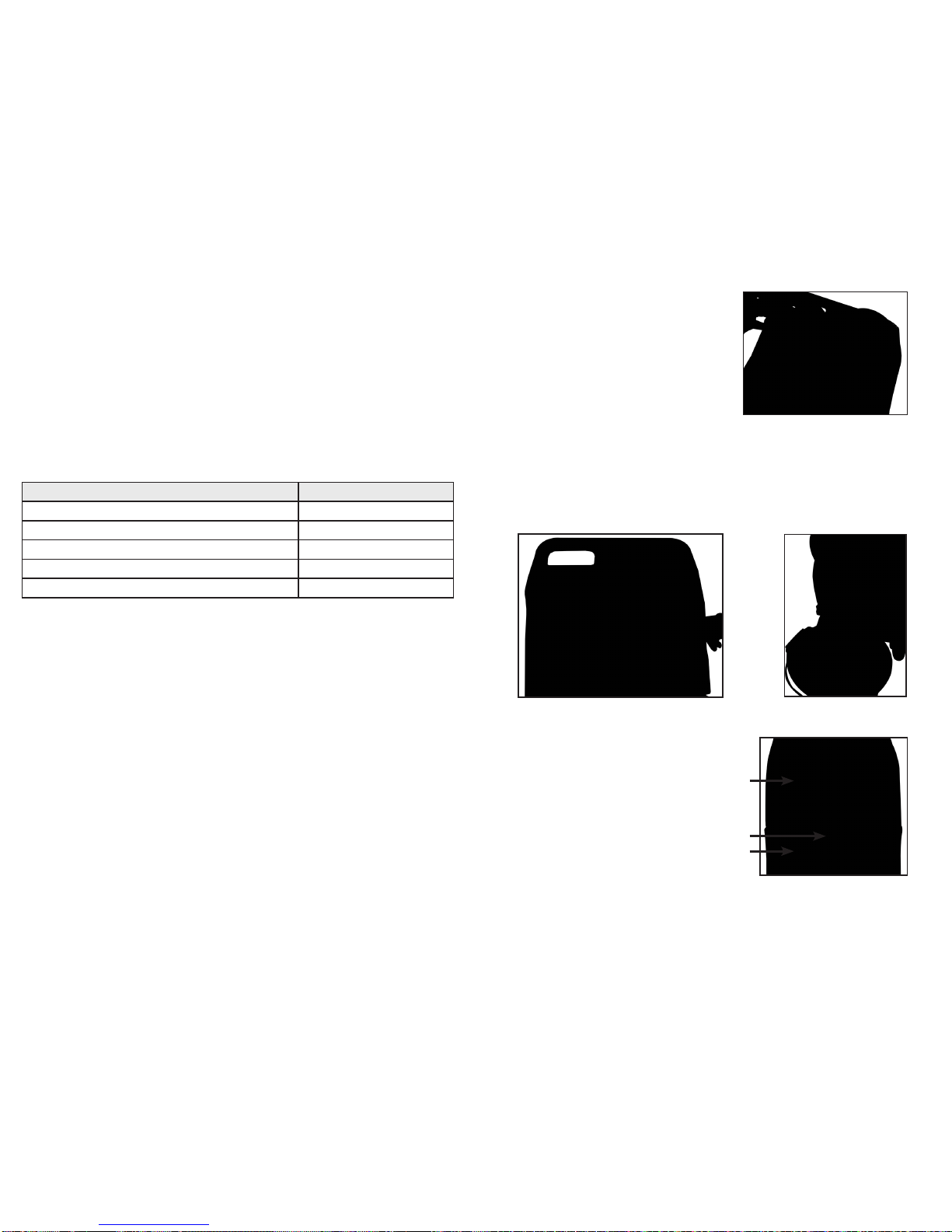

9.0 Machine Parts List

Drawing No. Item ID Item Description Qty.

1SN-12-ST-BLUGRAN 12-Gallon Solution Tank - Blue Granite 1.00

2 80-0017 Bulk Head tting for Extractor 1.00

3 10-0479 1/4” Male Close Nipple 1.00

4 10-0479 1/4" Male Close Nipple 1.00

5 10-0845 1/4" Strainer for Extractor 1.00

6SN-12-L-BLUGRAN 12-Gallon Lid - Blue Granite 1.00

7 80-0001 Extractor Exhaust Hose 0.40

8 10-0843 3/8" Black Hose for Extractor 8.80

9 10-0826 3/4" Hose Clamp for Extractor 4.00

10 80-0026 3/8 Barb x 1/4 MPT 90 Degree 2.00

11 10-0806 Barb Hose Fitting for Extractor 1.00

12 10-0379 8-32 x 3/8 Screw 8.00

13 10-0204 Motor Mount Back-Up Washer 18.00

14 10-0803 Splash-Proof Switch for Extractor 3.00

15 10-0809 Extractor 3-Hole Switch Plate 1.00

16 80-0200 Extractor Harness 1.00

17 SN-12-RT-BLUGRAN 12-Gallon Recovery Tank - Blue Granite 1.00

18 80-0008 1.5 PVC Female Adapter 2.00

19 10-0416-A 1-1/2" Black ABS Stand Pipe 2.60

20 10-0804-A Hatch Cover Gasket for Extractor 1.00

21 10-0804 Hatch Cover for Extractor 1.00

22 10-0419-A Screw for Extractor Hatch 12.00

23 80-0012 Float Assembly for Extractor 1.00

24 10-0805 Dump Valve for Extractor 1.00

25 10-0024 1-1/2" Black Vacuum Hose 1.30

26 10-0849 1-1/2" ABS Fitting 1.00

27 10-0848-B 1-1/2" 90 Degree ABS Street Elbow 3.00

28 10-0833 Motor Manifold Bolts for Extractor 10.00

29 10-0204 Motor Mount Back-Up Washer 18.00

30 10-0811 2-Stage Extractor Motor 2.00

31 10-0838 Pigtail for Extractor 1.00

32 10-0850 Strain Relief for Extractor 1.00

33 10-0851 Strain Relief Nut for Extractor 1.00

34 10-0822 Exhaust Grate for Extractor 3.00

35 10-1030-S2 2-Stage Extractor Motor Gasket 2.00

36 SN-12-MFLD Extractor Motor Manifold 2.00

37 10-0830 Hinge Keeper for Extractor 2.00

38 10-0821 Extractor Hinge 2.00

39 10-0820 End Cap for Rod on Extractor 4.00

40 SN-12-MB-BLKGRAN 12-Gallon Motor Base - Black Granite 1.00

41 10-0836 19" Axle for Extractor 1.00

42 10-0807 Wheels for Extractor 2.00

43 10-0840 Nylon Washer for Extractor Axle 8.00

44 10-0835-N Nut for Pump Bolt on Extractor 4.00

45 10-0834 Pump Flat Washer 10.00

46 10-0808 Caster for Extractor 2.00

47 10-0816 Caster Bolt 8.00

48 10-0379 8-32 x 3/8 Screw 8.00

49 10-0400-D Latch for Extractor 1.00

50 80-0026 3/8 Barb x 1/4 MPT 90 Degree 2.00

Returned Material Authorization (RMA) Procedure

Original purchaser must contact the manufacturer to follow correct RMA/warranty

procedures. Must include a copy of RMA Sheet enclosed in the box with returned item.

No returns shall be authorized unless the proper RMA procedures are followed. It is the

responsibility of the distributor to repair the customer’s equipment as soon as possible. If

the distributor does not have the facilities to repair the equipment, it may be shipped or

taken to an authorized service center for repair.

Customer must contact the manufacturer prior to working on or changing out any

parts, etc. Manufacturer must issue an RMA Sheet containing approved labor time and

replacement parts. Do not send parts or equipment back to manufacturer without an RMA

Number and approval. No labor will be paid for, nor part costs paid for or reimbursed that

have not been previously approved by manufacturer. All warranty work must be approved

and authorized to qualify and appropriate warranty procedures must be followed.

1.0 Safety Instructions

READ THIS MANUAL BEFORE USING YOUR CARPET EXTRACTOR.

KNOW THE PROPER OPERATION, CORRECT APPLICATIONS AND THE

LIMITATIONS OF THIS EQUIPMENT BEFORE USE.

Reduce the Risk of Fire, Electric Shock or Injury:

• Use only as described in this manual. Use only the attachments recommended by the

manufacturer.

• Test all outlets with an outlet tester before plugging machine into any outlet. Plug cord

into the nearest grounded outlet.

• DO NOT unplug by pulling on the cord, grasp the plug. DO NOT pull unit by the

cord.

• Keep cord away from heated surfaces.

• Never attempt adjustments or repairs while the machine is plugged in.

• DO NOT use if cord or plug are damaged.

• DO NOT use outdoors, in standing water on wet surfaces.

• Pay close attention when using machine near children.

• DO NOT pick up ammable or combustible materials or use machine where they may

be present.

• DO NOT leave machine outdoors, in extreme heat or cold. Harsh weather elements

will damage components and void warranty.

• Lift using only the appropriate handles.

• Always wear the appropriate clothing and safety equipment when operating the

machine.

• Keep all body parts, hair and loose clothing away from openings and moving parts.

• Use extra care when cleaning stairs. Never move the machine up or down stairs with

uid in the machine.

• Use common sense to protect yourself and others from injury when using the machine.