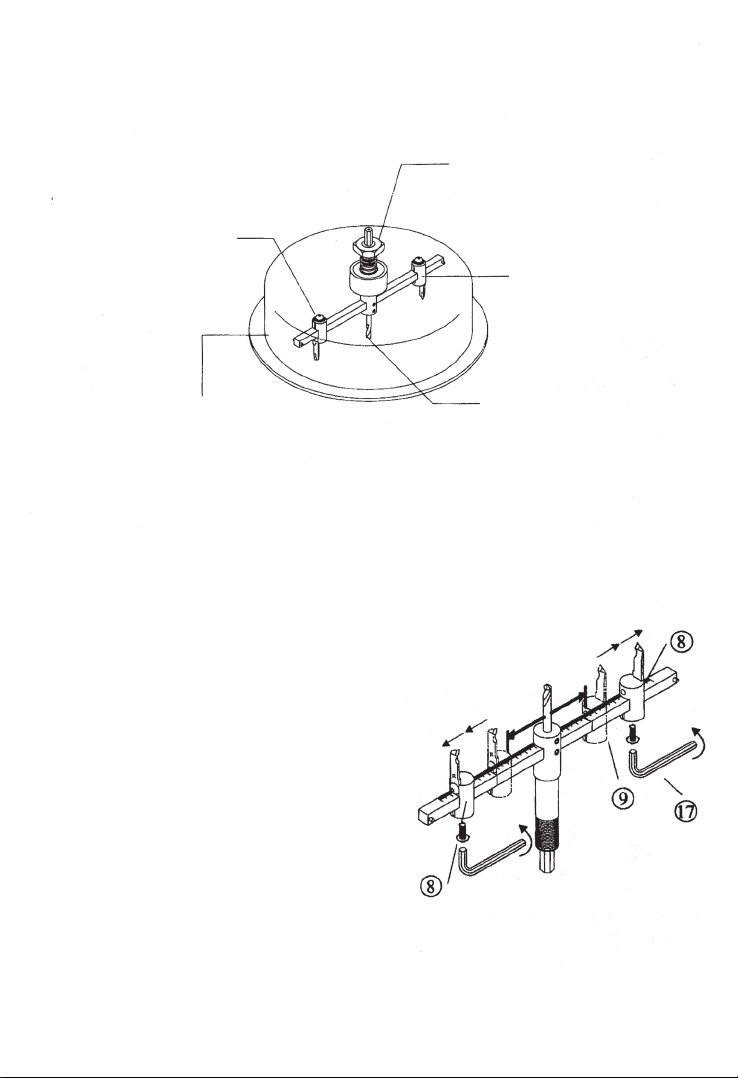

Insert the drill bit (1) into the upright axle (2) as shown

in the illustration and secure it in place by tightening

the screw (4) into the upper screw hole of the upright

axle (2) using the hexagon key (16) supplied.

Insert the transverse axle (3) into the square aperture

of the upright axle (2) as shown in the illustration.

Align the center hole of the transverse axle (3) with

the screw hole of the upright axle (2) and secure it in

place by tightening the screw (5) into the bottom

screw hole using the hexagon key (16) supplied.

Insert the right (R) cutting blade (6) with it’s R plane

surface facing outwards, into the upper aperture of

the adjustable cutter holder (8) and secure it in place

by tightening the screw (7) using the hexagon key (16)

supplied.

Insert the left (L) cutting blade (6) with it’s L plane

surface facing outwards, into the upper aperture of

the adjustable cutter holder (8) and secure it in place

by tightening the screw (7) using the hexagon key (16)

supplied.

Insert both of the right and left hand adjustable cutter

holders (8) fitted with the right and left cutting blades

respectively into the right and left sides of the

transverse axle (3) and secure them by inserting the

spring pins (10) respectively into the right and left side

pinholes of the transverse axle (3).

Tightening the screws (9) respectively into the screw

holes located at the bottom side of both of the right

and left side adjustable cutter holders (8) using the

hexagon key (17) supplied.

The completed assembly of the internal components

should resemble the illustration shown opposite.

1.

2.

3.

4.

5.

6.

7.

INTERNAL COMPONENTS

ASSEMBLY INSTRUCTIONS