4

Fault

Cause

2 Troubleshooting

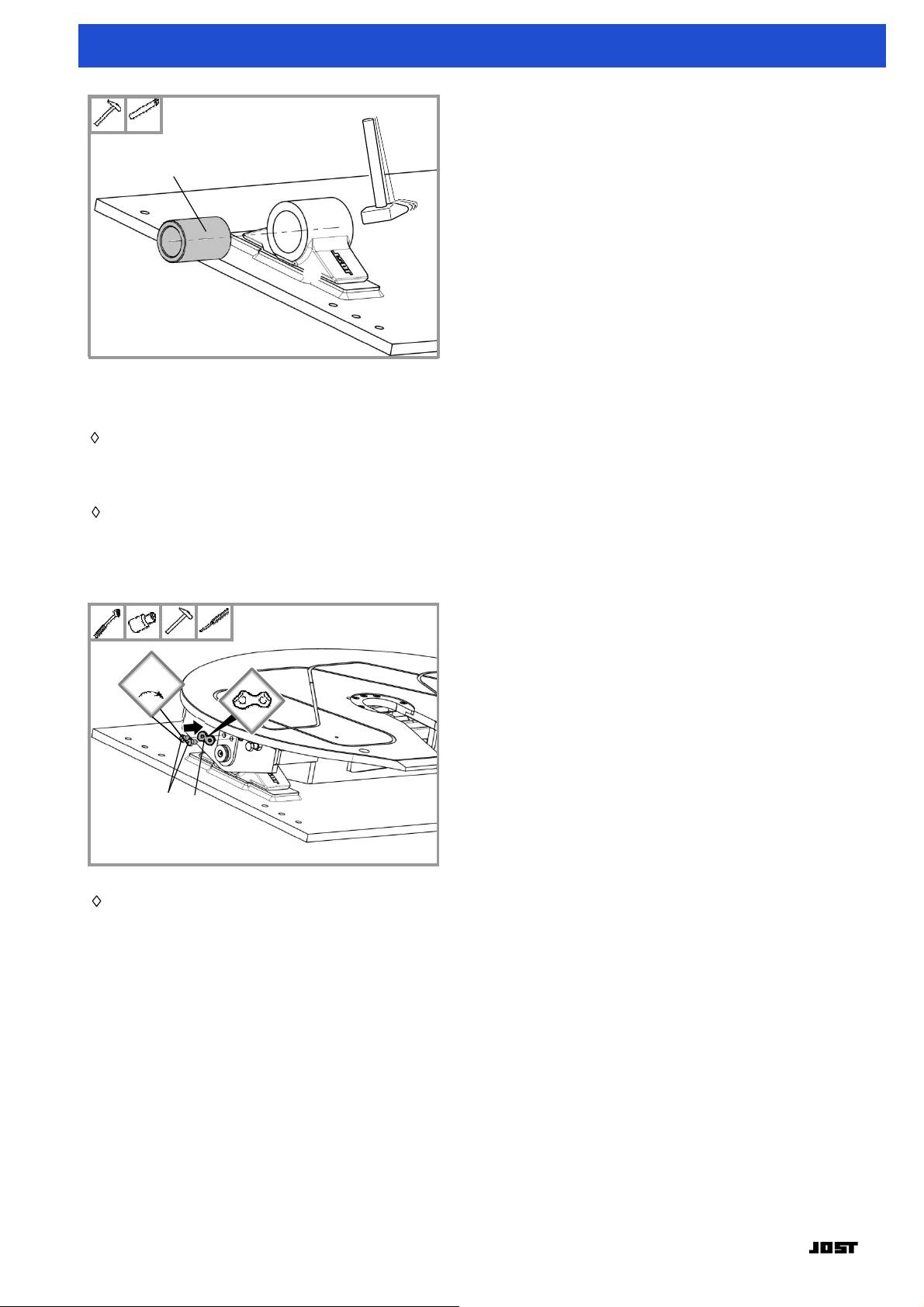

The fifth wheel

coupling will

not unlock.

1.

Relieve the strain on the fifth wheel coupling locking

mechanism.

2.

The fifth wheel coupling can be opened by force as

follows:

Undo the lock nut on adjusting screw SK 8301-301 and

tighten the screw (max. 30 Nm) to prestress the locking

mechanism. Swing the handle forwards to disengage the

lock. Have a second person on the opposite side of

the fifth

wheel coupling with a crow bar (20 mm in diameter and

approx. 600 mm long) hit the tip of the locking bar

SK 8101-

201 through the hole provided for this purpose in the rib so

as to release the bar. Then rectify the poor maintenance

problem, check the wear parts for signs of damage and

repair them if necessary and reset the locking mechanism.

Fifth wheel cou-

pling does not

stay in its pre-

set position.

Fifth wheel cou-

pling will not

lock.

1.King pin position

is

too high.

2.Skid plate uneven,therefore

the king pin is positioned

incorrectly.

3.King pin is not true to size or

is damaged.

4.Lock jaw

deformed.

5.Poor maintenance.

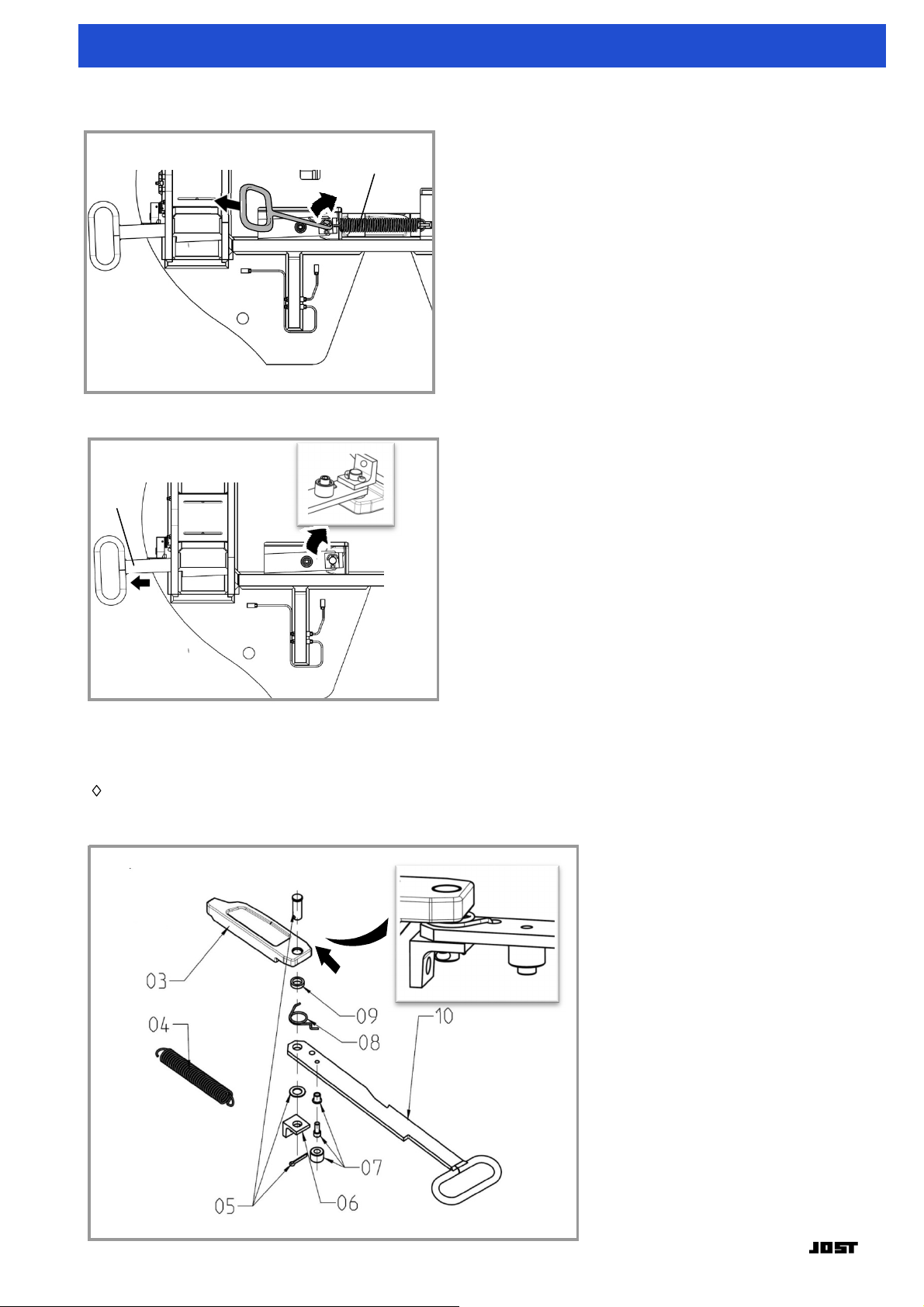

6.Double tension spring

defective.

7.Lever and/or handle

is

bent.

1.The skid plate should be at the same level or max.

50 mm

lower than the fifth wheel coupling.

2.Change the skid plate. Permitted flatness tolerance

max.

2 mm.

3.Replace the kingpin.

4.ReplacelockjawSK8101-201

5.Open the mechanism and greaseit.

6.Replace double tension springSK8301-210.

7.Replace or straighten the lever SK 8301-214 and

handle

SK8301-213.

Solution

1.The semi-trailer unit is not flat

or is pulling on the coupling.

2.Poor maintenance, damageto

the lock jaw or locking bar or

incorrect lock jaw

adjustment.

1.ReplacelockjawSK8101-201

2.ReplacespringSK2106-01.

3.Open the mechanism.

1.Lock jaw

deformed.

2.Spring defective.

3.Poormaintenance.