9

SOLAR SYSTEMS

manual and maintenance

What happens when you go on holidays

When you go on holidays or leave your house for more than a couple of days then you are

not using any hot water out of your hot water cylinder. This means that the solar system

heats your cylinder on day 1 and then on day 2 it has no water left to heat because the

cylinder was heated the previous day and no water has been taken out of the hot water

cylinder. To change any options including setting up the controller for going on holidays

you must rst enter the service menu of the controller. To do this, follow these steps.

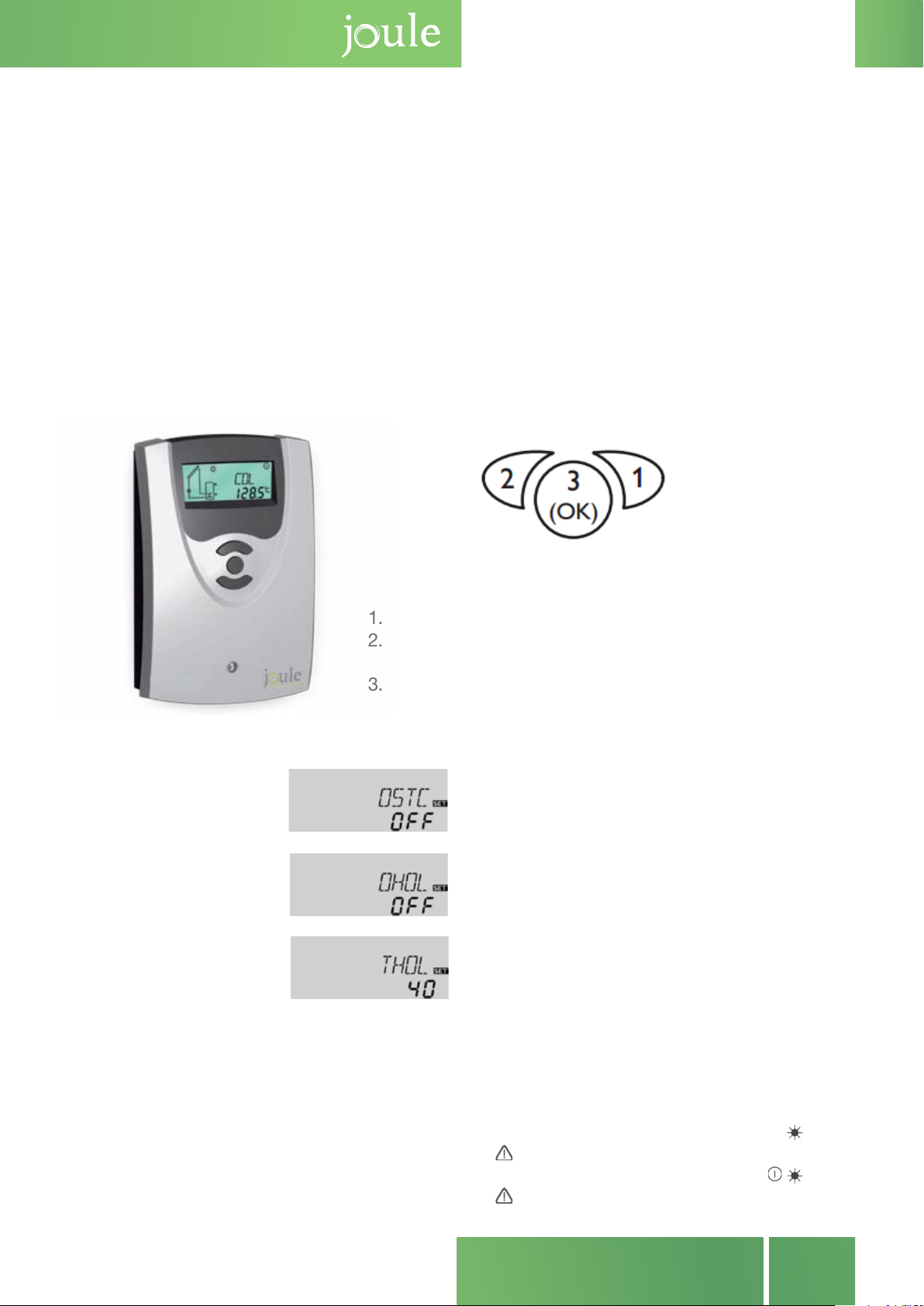

1. Tap button 1 until you reach the TIME screen

2. Press and hold button 1 until the screen moves.

(3 seconds to move).

3. Tap button 1 until you reach the desired screen.

The three buttons of the BS/4 controller

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function

When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

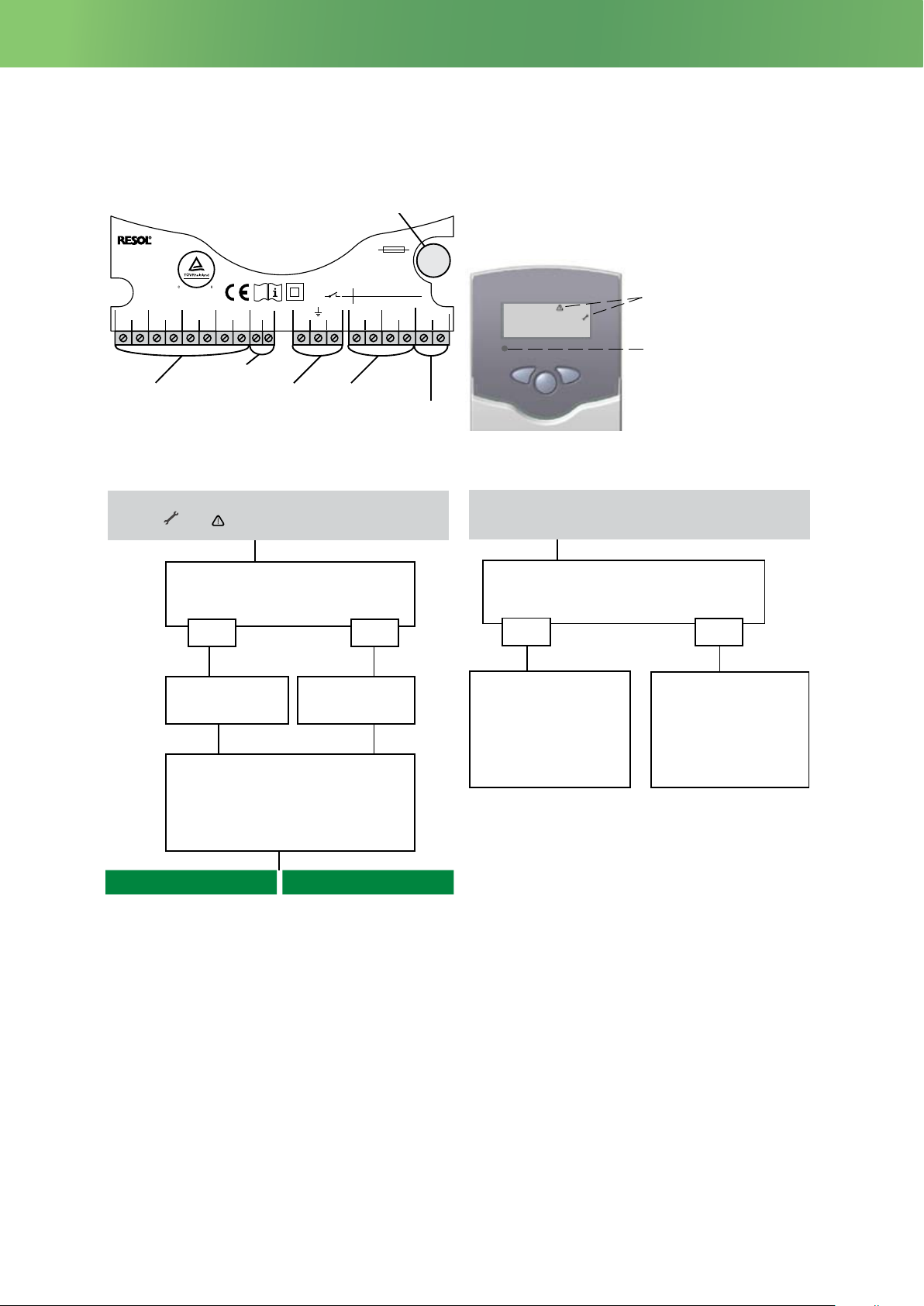

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

When the store cooling function is activated, the

controller aims to cool down the store during the

night in order to prepare it for solar loading on the

following day.

If the adjusted maximum store temperature S MX

is exceeded and the collector temperature falls

below the store temperature, the system will be re-

activated in order to cool down the store. Cooling

will continue until the store temperature has fallen

below the adjusted maximum sture temperature S

MX again. A xed hysteresis of 2K [4 °Ra] is set for

this function.

Reference treshold temperature dierences for the

store cooling function are DT O and DT F.

If no DHW consumption is expected for a longer

period of time, the additional holiday cooling option

OHOL can be activated in order to extend the store

cooling function. The adjustable temperature THOL

then replaces the maximum store temperature S

MX as a switch-o temperature for the store cool-

ing function.

When the holiday cooling function is activated,

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

and

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

(ashing) are shown on the display.

While the holiday cooling function is active,

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

and

DeltaSol®BS/4

© RESOL_12089_deltasol_bs4_v2.monen.indd

23 |

CMN:

Collector minimum temp.

Adjustment range:

10 ... 90 °C [50...190 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

10 °C [50 °F]

Collector minimum limitation option

OCN:

Collector minimum limitation

Adjustment range: OFF / ON

Factory setting: OFF

If the collector minimum limitation option is activated,

the pump (R1) is only switched on if the adjustable

collector minimum temperature is exceeded.The minimum

temperature prevents the pump from being switched on too

often at low collector temperatures. A fixed hysteresis of

5 K [10 °Ra] is set for this function

If the collector minimum limitation is active, (flashing) is

shown on the display.

Antifreeze option

OCF:

Antifreeze function

Adjustment range: OFF / ON

Factory setting: OFF

The antifreeze function activates the loading circuit between

the collector and the store when the temperature falls below

the adjusted antifreeze temperature. This will protect the

fluid against freezing or coagulating.If the adjusted antifreeze

temperature is exceeded by 1 K [2 °Ra], the loading circuit

will be deactivated.

When the antifreeze function is activated, is shown on

the display. If the antifreeze function is active, and

(flashing) are shown on the display.

Note:

Since this function uses the limited heat quantity

of the store, the antifreeze function should be

used in regions with few days of temperatures

around the freezing point.

The antifreeze function will be suppressed if the

store temperature falls below 5 °C [40 °F] in

order to protect the store from frost damage.

CFR:

Antifreeze temperature

Adjustment range:

-40.0 ... +10.0 °C

[-40.0 ... +50.0 °F]

in steps of 0.5 K [1 °Ra]

Factory setting:

4.0 °C [40.0 °F]

Store cooling function When the store cooling function is activated, the controller

aims to cool down the store during the night in order to

prepare it for solar loading on the following day.

If the adjusted maximum store temperature S MX is

exceeded and the collector temperature falls below the

store temperature, the system will be reactivated in order

to cool down the store. Cooling will continue until the store

temperature has fallen below the adjusted maximum store

temperature S MX again. A fixed hysteresis of 2 K [4 °Ra]

is set for this function.

Reference threshold temperature differences for the store

cooling function are DT O and DT F.

If no DHW consumption is expected for a longer period of

time, the additional holiday cooling option OHOL can be

activated in order to extend the store cooling function.The

adjustable temperature THOL then replaces the maximum

store temperature S MX as a switch-off temperature for the

store cooling function.

When the holiday cooling function is activated,and

(flashing) are shown on the display.

While the holiday cooling function is active, ,and

(flashing) are shown on the display.

OSTC:

Store cooling option

Adjustment range: OFF /ON

Factory setting: OFF

THOL:

Holiday cooling temperature

Adjustment range:

20 ... 80 °C [70 ... 175 °F]

in steps of 1 K [1 °Ra]

Factory setting:

40 °C [110 °F]

OHOL:

Holiday cooling option

Adjustment range: OFF /ON

Factory setting: OFF

Note:

If OSTC or OCF is active,the collector minimum

function will be overridden. In that case, the

collector temperature may fall below CMN.

(ashing) are shown on the display.