6

SafeRoofAccessToWork

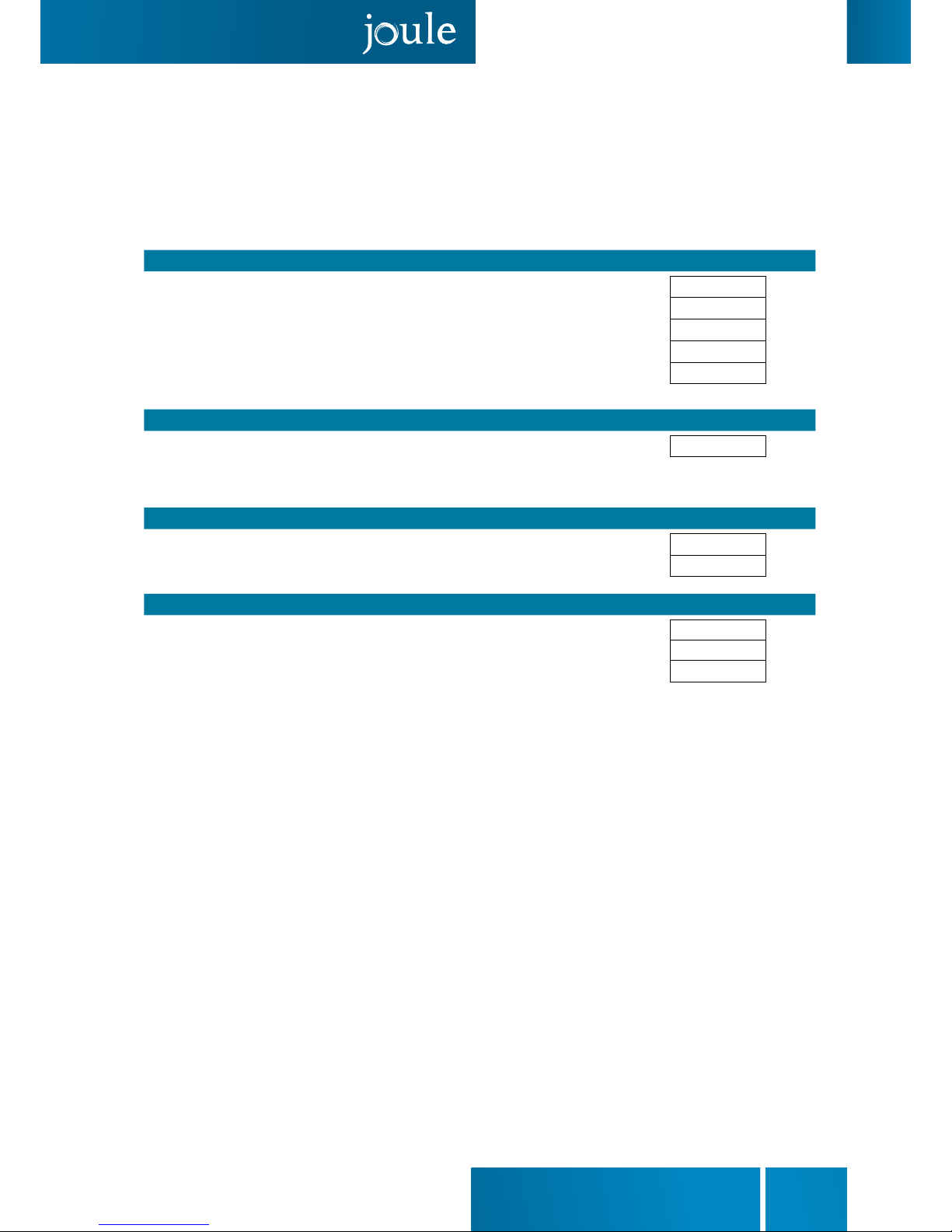

Isthereadequateaccesstoareaofhousetomountscaoldingorladders? (yes/no)

Istheresteadyandsecurebaseonwhichtomountscaoldingorladders? (yes/no)

Arethescaoldingandorladderstforuseintended? (yes/no)

Allinstallerstrainedinworkingatheights? (yes/no)

Areallharnessandothersafetyequipmentworkingcorrectly? (yes/no)

Allworkcarriedoutshouldbeinaccordancewithallrelevantgoodpraticesandorcurrentbuildingstand-

ards.Allcurrentregulationsshouldbefollowedinrelationtoworkingatheights.Nothingstatedinthisguide

takespre-sedenceovercurrentstandards.

ConditionofRoof

Whatarethecentresofroofrafterswheresolarcollectoristobemounted(eg400mm)? (mm)

Whatisthesizeofroofrafters(eg6x2”,7x2”,8x2”)? (inch)

Are roof rafters cross braced? (yes/no)

Is any of the timber showing discolouration (indicating rot)? (yes/no)

To determine the total load on the roof you must get the total weight of the collectors and divide this weight

bythenumberofroofxingboltsoranchorsusedtoholdthecollectorontheroof.Thiswillgiveyouthe

weight of the solar panels on each point of the roof. You must then carefully review the points where the col-

lectorsareconnectedtotherooftoensurethattheseexactpointscantaketheanticipatedload.

Wherethereissignsofdiscolourationacloserexaminationwillberequried.Ifblackspotsarefoundonthe

timberthisindicatesaleakwhichneedsattention.Ifthetimberappearsbrownandakythen thetimber

may need to be replaced. If the situation is unclear a structural engineers report should be obtained prior to

completinganyfurtherwork.

EectsofSnowLoads

What is the estimated annual snow fall for this part of the country? (mm)

TheestimatedsnowloadforallpartsofirelandmaybefoundfromhistoricaldatalocatedonMetEireann’s

website. www.met.ie

What is the total extra weight to be assumed from a snow fall? (kg)

Irishsnowweighsapprox150kgperm3.Todeterminetheextraweightthesnowwilladdtothesolarpanels

you may assume the following formula. (snow fall in meters x area of panel on the roof in m2x150kg/m3)

Whenyoundoutthetotalextraweightofthesnowaddittothetotalweightofthecollectorontheroof.

The using this new weight examine the roof structure to ensure its suitability. You do not need to consider

the snow load when installing evacuated tubes.

EectsofWindLoad

The evacuated tube collector is exempt from consideration of wind loading for the same reason as the snow loading.

Whenconsideringatpanelswindtestshavebeenconductedthatensurethattheyandtheirxingbracketscanwithstandall

recorded wind forces in Ireland when mounted on a four storey house or less.

Risk Assesment

6