SL600AC SLIDING GATE OPERATOR

18

zThree-button mode external button switch (not supply):

press ‘OPEN’ button, the gate opens. Press ‘STOP’ button, the

gate stops. Press ‘CLOSE’ button, the gate closes.

zSingle-button mode external button switch / keypad (not

supply): With each press of the button, the gate will close, stop,

open or stop cycle.

zAuto-close function: This feature can be selected to make the

gate stay open for some seconds before it automatically closes.

The auto-close time can be adjusted to between 12, 24 and 36

seconds.

zSafe guard (Infrared photocell): If infrared beam is interrupted

during closing, the gate will reverse and go open immediately.

This feature will not function if the gate is in fully opened and

closed positions or during opening.

zOpen priority: The gate will return to open if press ‘OPEN’

button of external button switch during closing.

zLimit switch: The switch is used to accurately stop the gate in

the opened and closed positions.

If the gate stops at opened position when the limit switch is

reached, the gate will not move if you press ‘OPEN’ button.

If the gate stops at closed position when the limit switch is

reached, the gate will not move if you press ‘CLOSE’ button.

zThe device is installed with a thermal protector, the thermal

protector will switch off the motor automatically in case of the

temperature is higher than 120°C and switch on the motor

automatically when the temperature is lower than 85°C±5 °C.

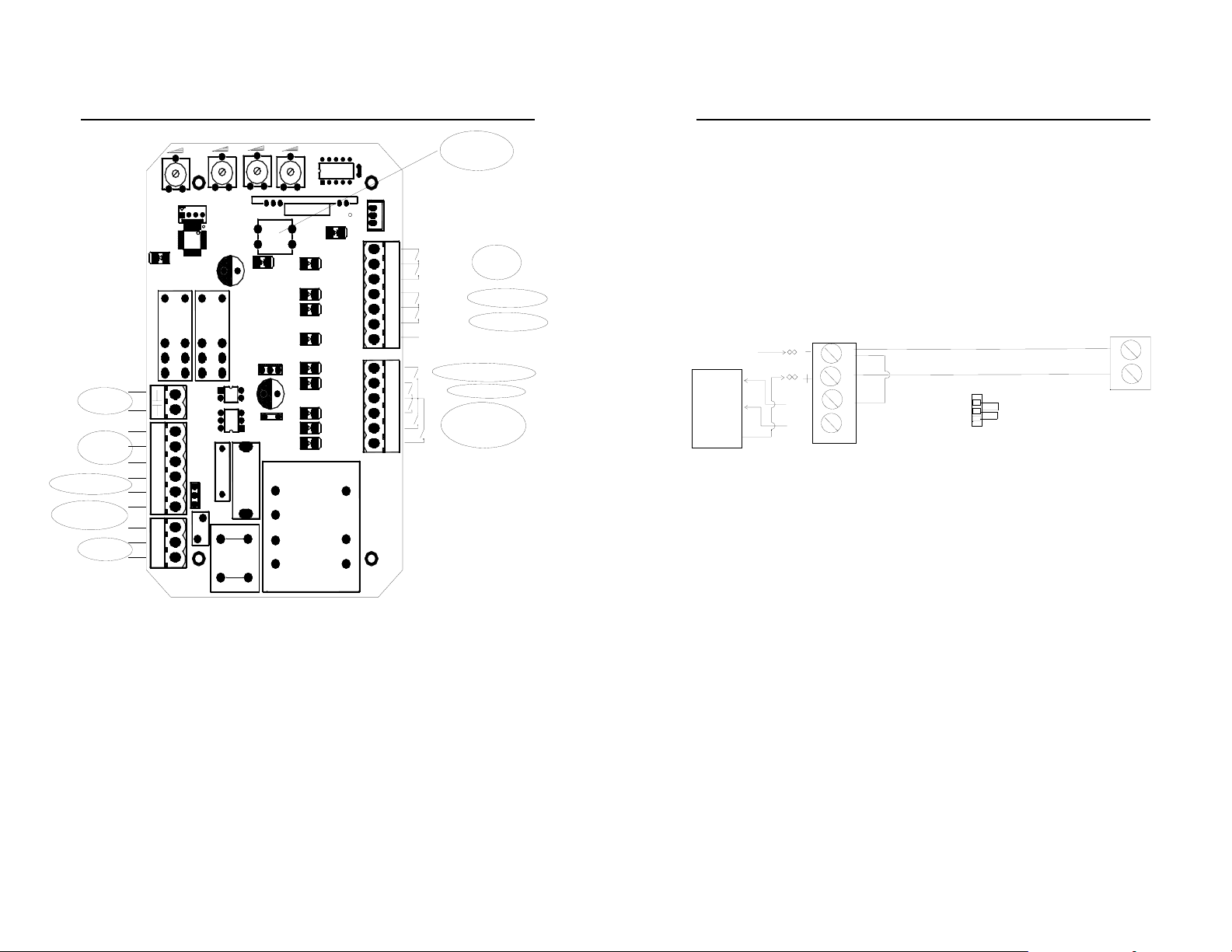

9. LED indicate

a. LED of Power indicated the input power.

b. LED of LEARN indicated the transmitter learn status.

c. LED 1 indicate the ‘CLOSE’ external button, if the button is

SL600AC SLIDING GATE OPERATOR

19

pressed the LED will light.

d. LED 2 indicate the ‘OPEN’ external button, if the button is

pressed the LED will light.

e. LED 3 indicate the ‘STOP’ external button, if the button is

pressed the LED will light.

f. LED 5 indicate the ‘O/S/C’ external button, if the button is

pressed the LED will light.

g. LED 6 indicate the ‘pedestrian switch’ external button, if the

button is pressed the LED will light.

h. LED 7 indicate the ‘infrared sensor’ status, if the output is

connected the LED will light.

i. LED 9 indicate the ‘Loop detector’ status, if the output is

connected the LED will light.

j. LED 10 indicate the ‘Close limit switch’ status, if the switch is

connected the LED will light.

k. LED 12 indicate the ‘Open limit switch’ status, if the switch is

connected the LED will light.

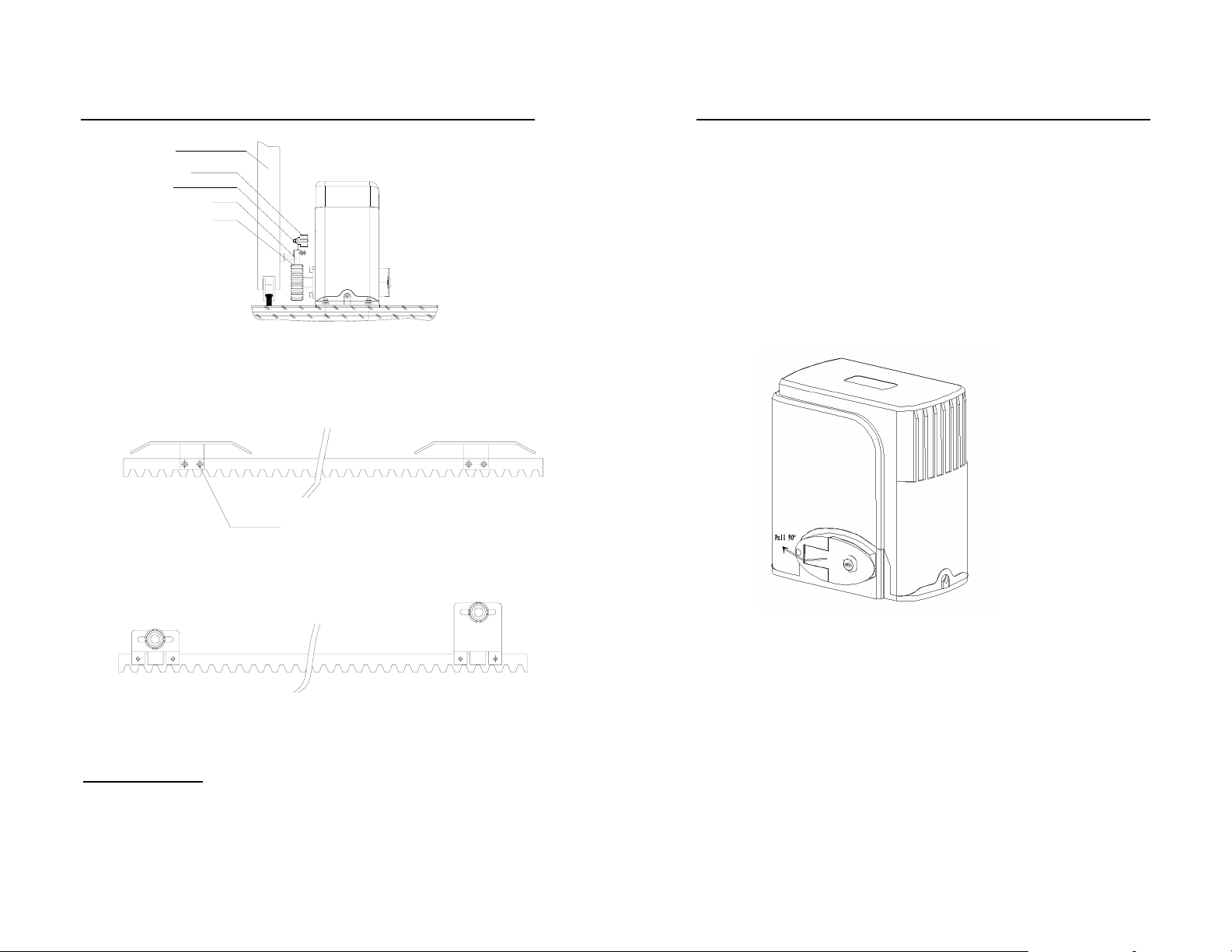

All these LED position see the Fig.8

10. Maintenance

zCheck the door once a month. The door should be carefully

checked for balance. The door must be in good working order.

zWe suggest for safety reasons, photocells be used on all gates.

zDisconnect from mains supply before replacing bulb.

zBe sure to read the entire manual before attempting to perform

any installation or service to the door operator.

zOur company reserves the right to change the design and

specification without prior notification.