1.Application

Air and stove heater (hereinafter referred to as

the fuel stove) is an integrated stove, heating

air as one of the special RV fuel stove.The

stoves can also be used for cooking in the wild,

such as on ships.

2. Main Technical Data

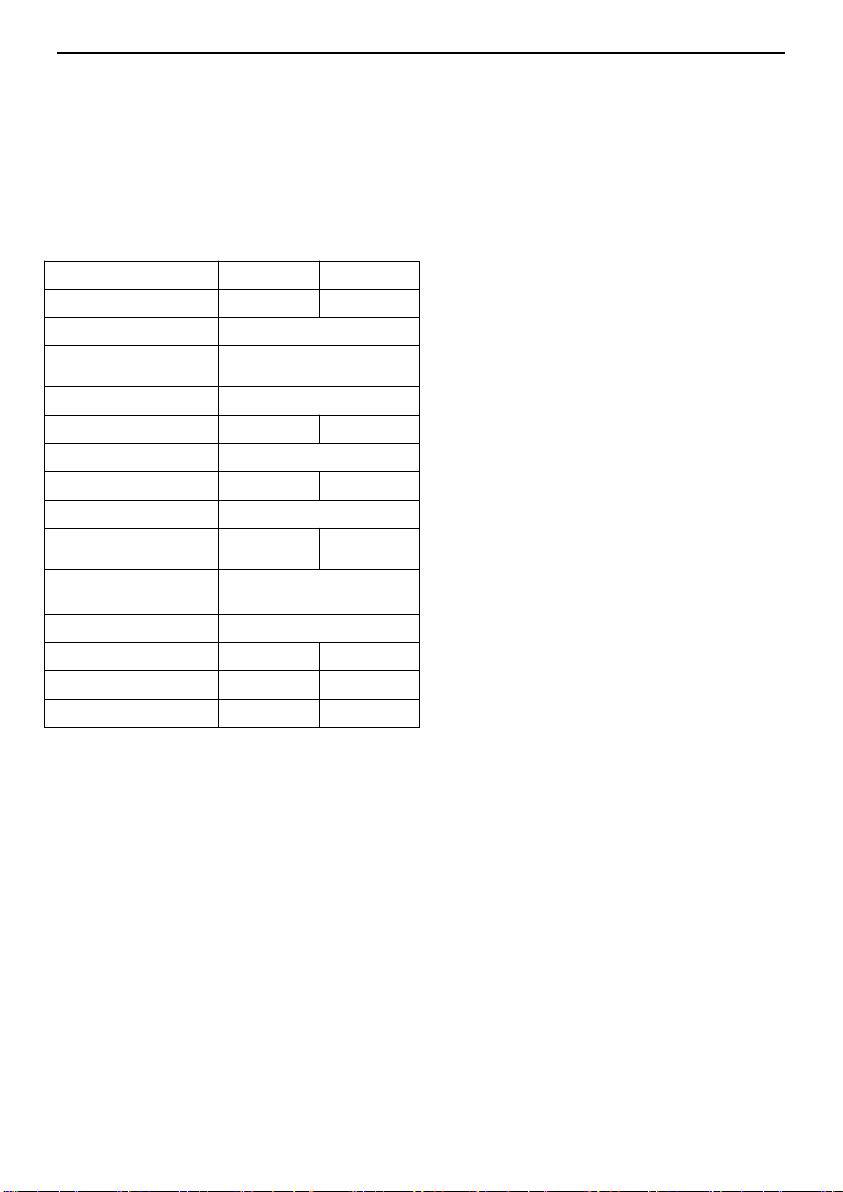

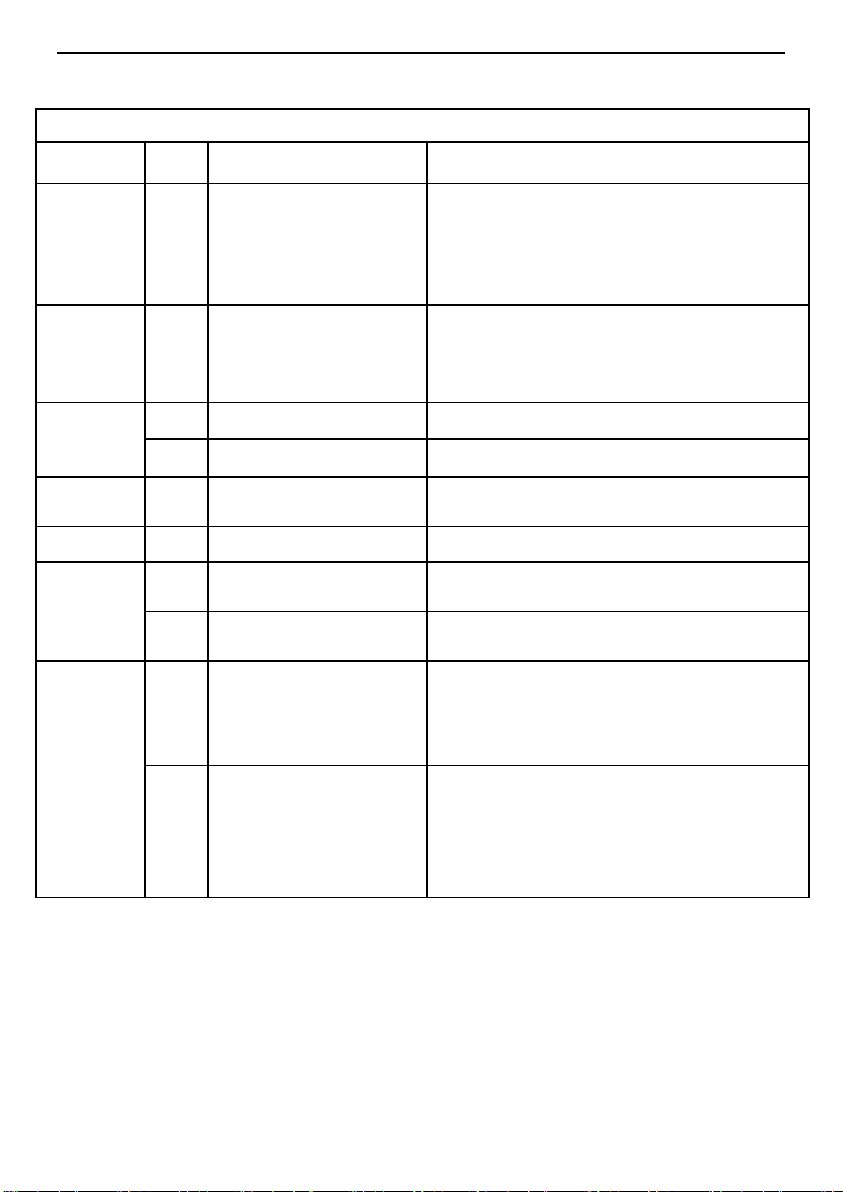

Table1

3. Function

This fuel stove is a safe diesel stove with no

open flame.The fuel stove is not allowed to be

used during running.

--Cooking mode

Adjust the heating power by controlling the

switch to cook and heat various kinds of food

-- Air conditioning mode

Close the upper cover and adjust the setting

temperature by controlling the switch to heat

the room temperature.

4. Safety instructions

Safe working environment

-- The danger of toxic fumes.If the vehicle is

parked in a closed room, in an enclosed space

(such as a garage, repair shop), the exhaust gas

from the fuel stove can be toxic.Therefore, in

the enclosed space to turn off the fuel supply of

the fuel stove, through the control switch to

turn off the fuel stove.

-- Thermosensitive objects (e.g., spray cans) or

flammable materials/liquids should not be

stored in the same compartment as the

equipment because, in some cases, the area

may be affected by high temperatures.

-- At all times, keep exhaust pipe and

combustion air inlet free from contamination

(slush, ice, leaves, etc.).

Obligations of the operator/owner

It is the owner's responsibility to operate the

equipment correctly.

The fuel system must comply with the

technical and administrative regulations of the

state.Must abide by national legislation and

regulations.

Safe operation

-- Make sure the interior is well

ventilated.When the burner is turned on, there

may be some smoke or odor due to dust or

dirt.Especially if the equipment has not been

used for a long time.

-- The integrity and tight fit of the intake and

exhaust pipes must be checked periodically,

especially at the end of a long journey.

Do not spray water directly into the exhaust

hood while cleaning the vehicle.

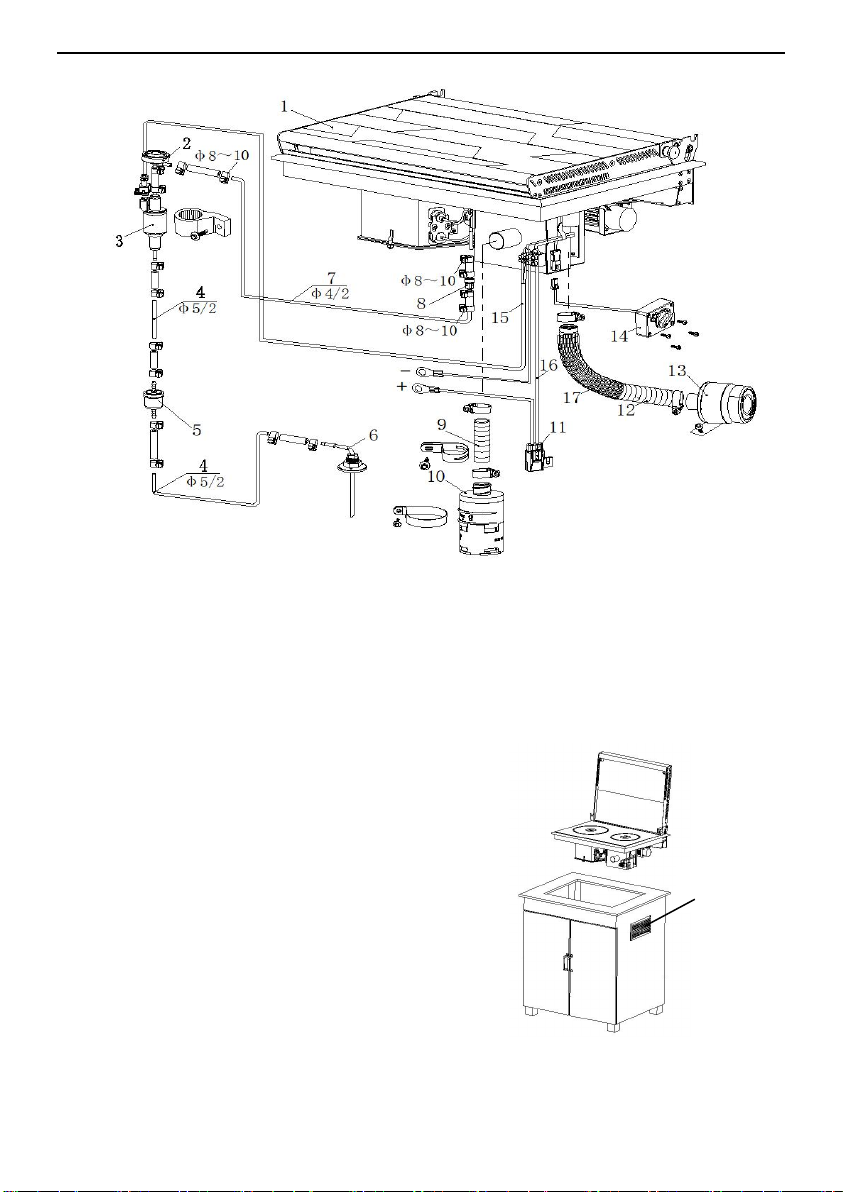

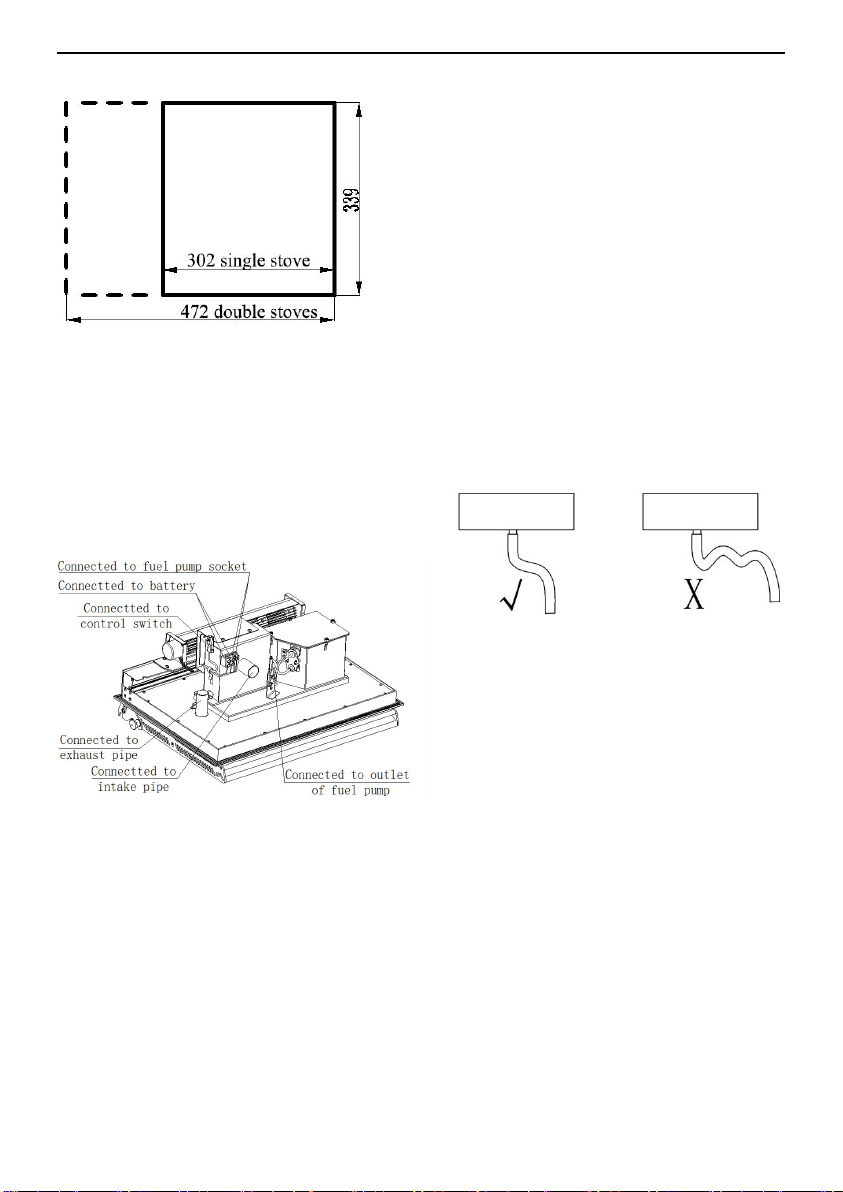

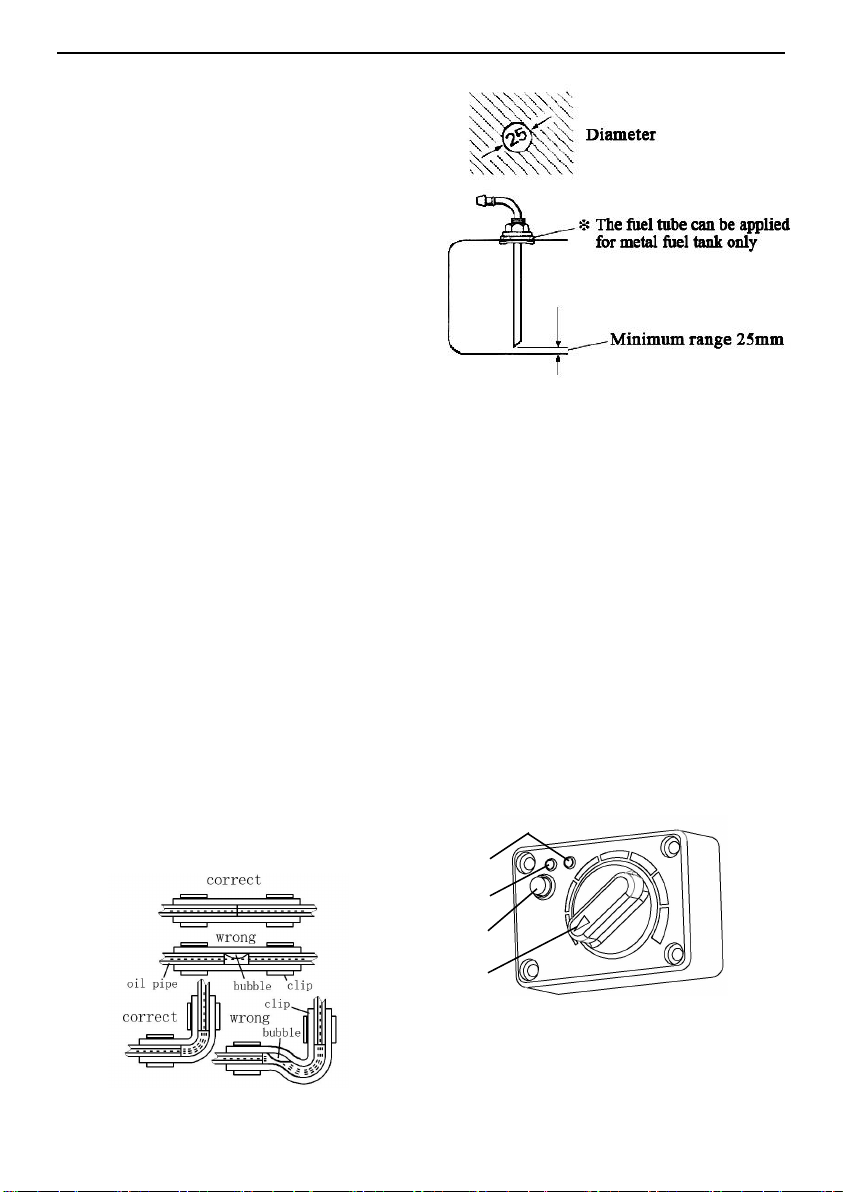

5. Installation

Typical installation diagram of fuel stoves

figure 1.

★Must be authorized by the company's

professional installation, maintenance!

The Company shall not be liable for any of the

following ACTS:

-- Refitting fuel stoves and accessories.

-- Modification of exhaust pipe path and

accessories.

-- Do not follow the operation installation

instructions.

-- Do not use our special accessories.

--Overheat damage caused by idle burning or