Safety

1.3.2 Warning of property damage

WARNING

Risk of water damage or damage

to property

The device may only be installed by

qualified technical personnel.

The installation room must be dry and

free from frost.

The ambient temperature must not

exceed 30 °C! In higher temperatures

or direct sunlight, material damage may

occur up to and including breakage of

device parts.

An adequately sized waste water con-

nection (e.g. floor drain) in compliance

with DIN 1986 must be provided.

In order to ensure safe drinking water

hygiene, a free discharge of the waste

water acc. to DIN EN 1717 must be

ensured.

The pipe must be able to safely sup-

port the device (weight: see chapter 7).

If necessary, the pipes must be provided

with additional fastenings or support.

If no bypass valve is installed, a shut-

off valve must be installed upstream of

the unit in order to interrupt the water

supply during installation, maintenance,

repair or malfunction of the device.

Install the device in a vertical position

(± 5°). Otherwise, water may escape and

cause water damage.

For the installation of the device in

domestic water piping, only use the sup-

plied built-in rotary flange (see chapter

3.2).

The flange surface of the rotary flange

fitting must be upright!

The rotary flange fitting must be fitted so

that it is free from mechanical stress or

strain. Otherwise mechanical damage to

the pipe or the rotary flange fitting up to

and including breaks can result.

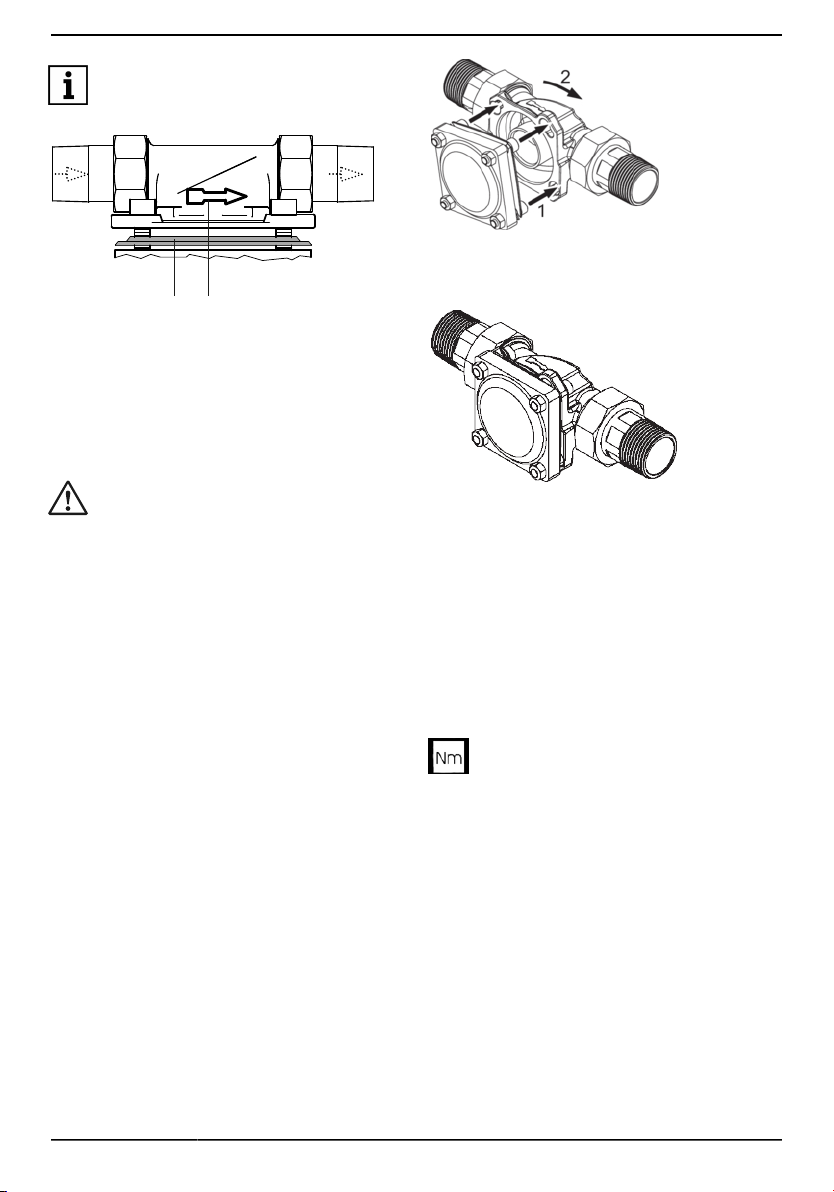

For proper sealing the profile of the pro-

file flange seal must point towards the

rotary flange fitting (see Figure 3).

Only operate the device in a technically

faultless condition:

•Check for damage prior to installa-

tion.

•Immediately have any malfunctions in

operation rectified by qualified tech-

nical personnel.

Persons who, due to their physical, sen-

sory or mental abilities or their inexperi-

ence or lack of knowledge, are unable to

operate the device safely may not oper-

ate it without supervision or instruction

from a responsible person.

Regular backwashing of the device is

required to ensure safe drinking water

hygiene (see chapter 4.2.1).

Before carrying out a backwash, ensure

that the wastewater connection is func-

tional.

At the end of the backwashing process,

turn the handwheel until it engages so

that no more backwash water escapes.

Otherwise, water may constantly escape

and cause water damage.

Do not use household cleaning agents

to clean the outside of the device, but

only use clear water to avoid embrittle-

ment of the plastic.

The device may only be repaired by

qualified technical personnel.

Only use original spare parts for repairs.

Before performing work on the device

that goes beyond pure operational use,

the device must be depressurised! If

this is ignored, the result may be uncon-

trolled escape of water resulting in water

damage to the building/home.

1703301 • 2020/07 JUDO JPM-QC 5