i

CONTENTS

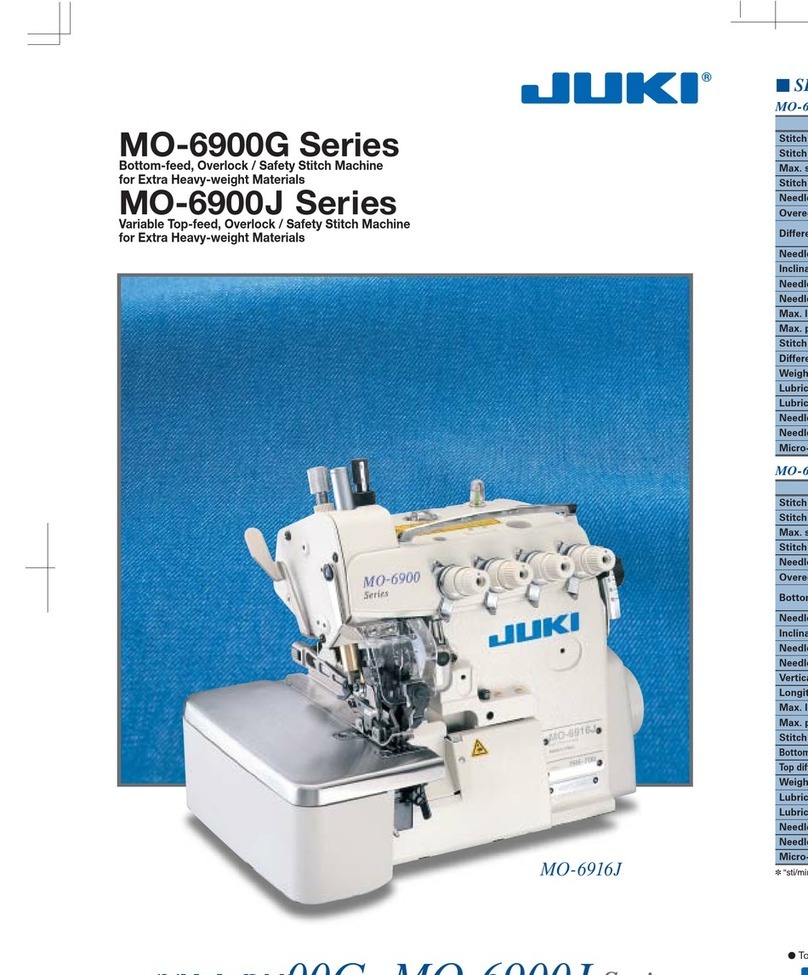

!. SPECIFICATIONS .............................................................................................1

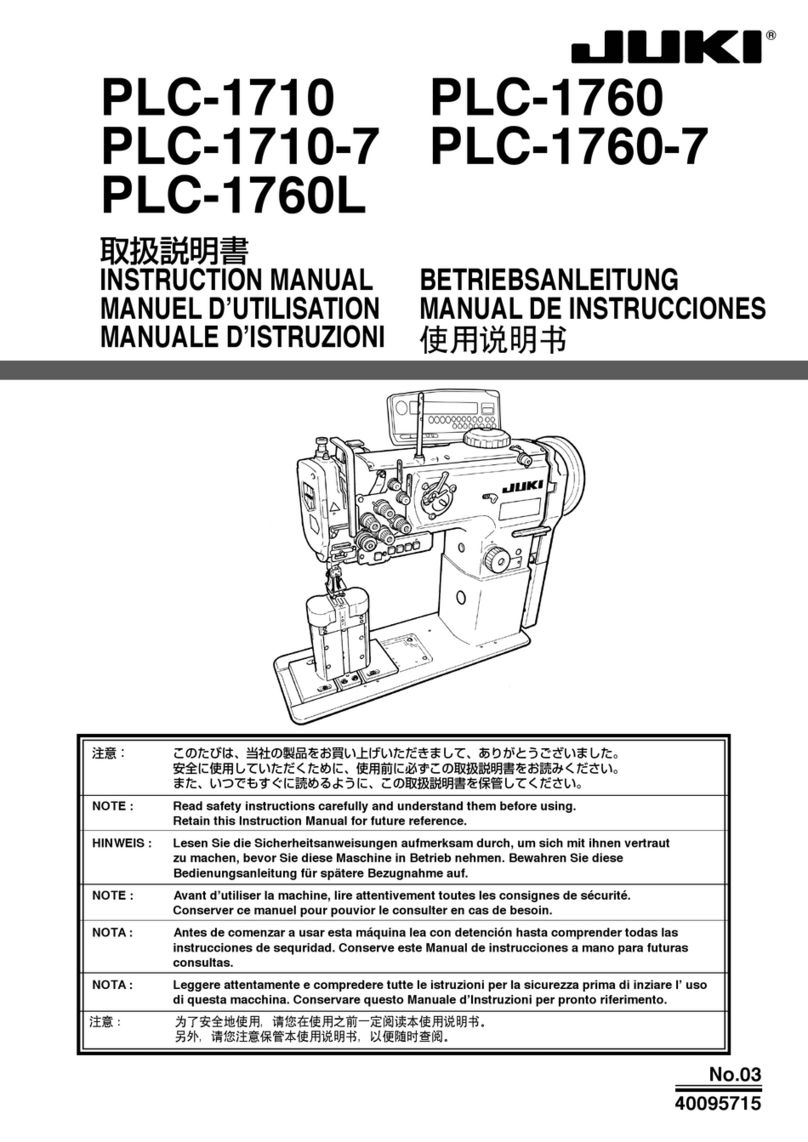

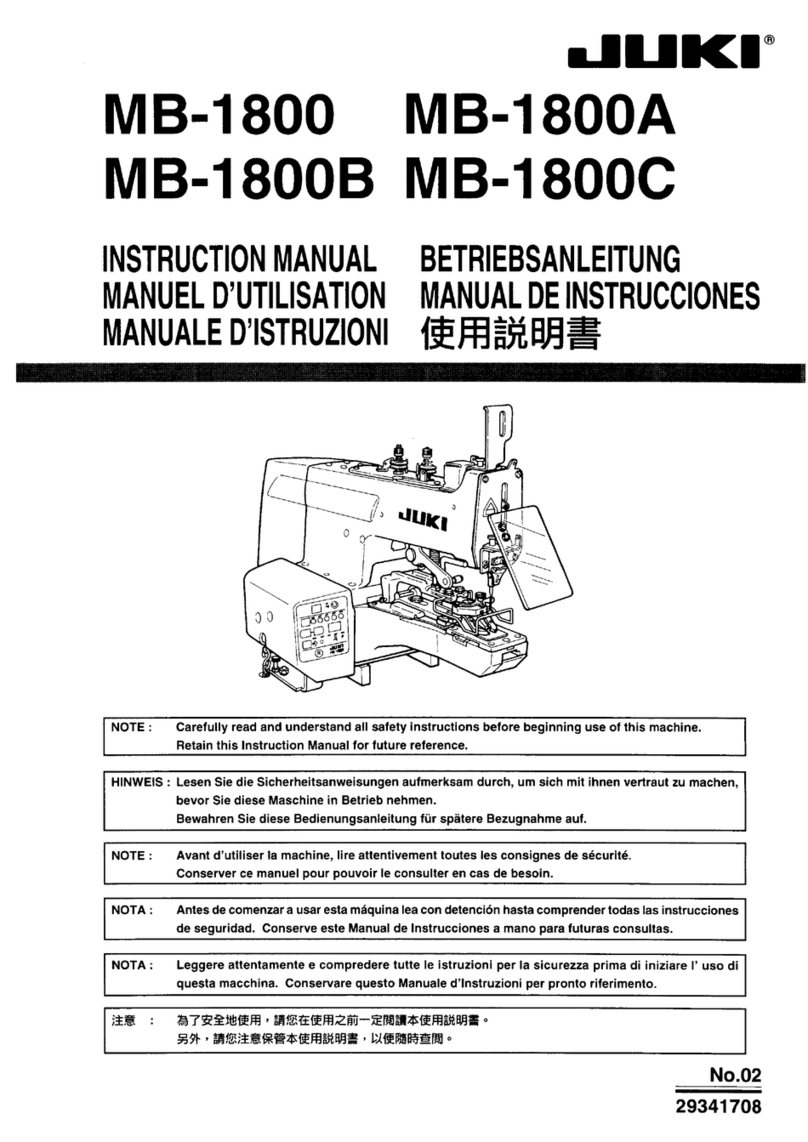

@.NAME OF EACH COMPONENT ....................................................................... 2

1. Name of the main unit ....................................................................................................................... 2

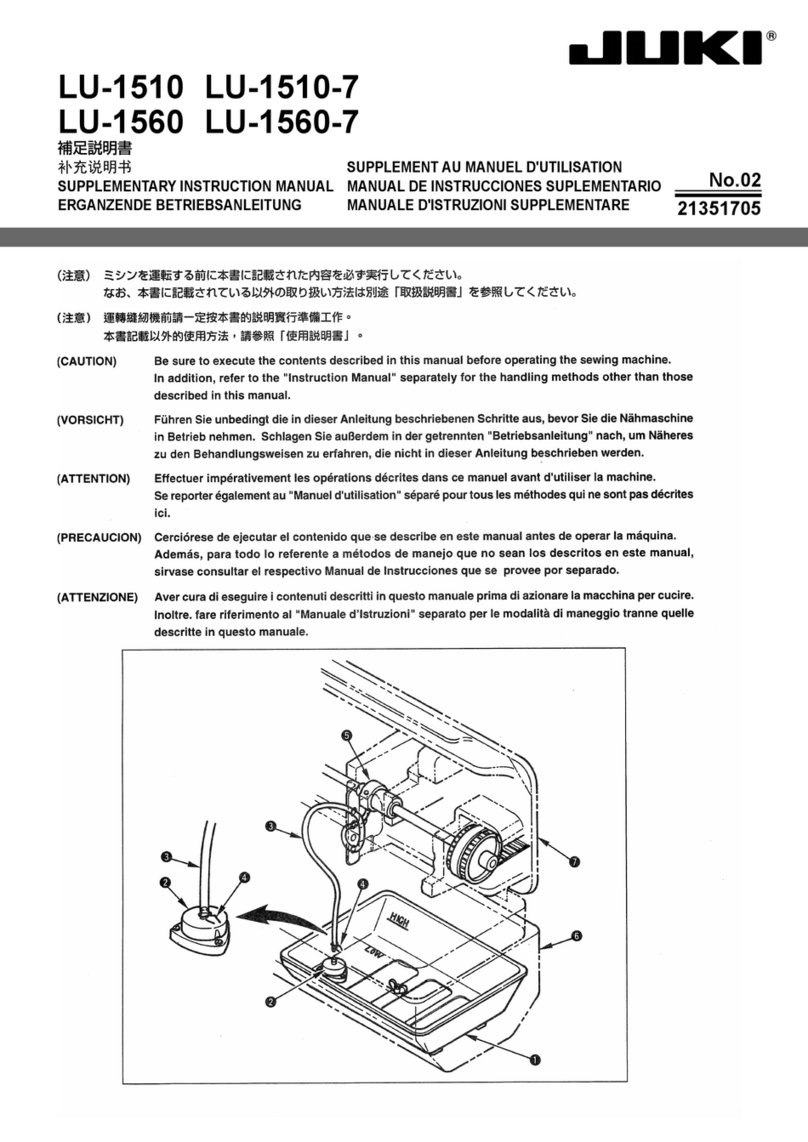

#. INSTALLATION .................................................................................................3

$.PREPARATION OF THE SEWING MACHINE ..................................................7

1. Attaching the needle ......................................................................................................................... 7

2. Threading the machine ..................................................................................................................... 7

%.OPERATION OF THE SEWING MACHINE....................................................... 8

1. Names of the operation panel switches .......................................................................................... 8

2. Pattern table....................................................................................................................................... 9

3. Operating procedure of the operation panel (basic volume) ...................................................... 10

4. Stitching without the crossover thread ......................................................................................... 11

5. Operating procedure of the operation panel (applied volume)................................................... 11

6. How to use the memory switch...................................................................................................... 13

^.ADJUSTMENT OF THE SEWING MACHINE ................................................. 14

1. Thread tension adjustment ............................................................................................................ 14

2. Adjustment of thread hauling amount .......................................................................................... 14

3. Timing of thread tension release ................................................................................................... 14

4. Adjustment of the thread tension guide on the face plate .......................................................... 15

5. Adjustment of needle-to-looper relation .......................................................................................15

6. Adjustment of the needle guide ..................................................................................................... 16

7. Adjustment of the thread trimming mechanism........................................................................... 16

8. Adjusting the height of the button clamp unit .............................................................................. 17

9. Adjusting the work pressing force ................................................................................................ 17

10. Adjustment of the button clamp stop lever .................................................................................. 17

11. How to adjust the position of the feed origin ...............................................................................18

12. Installing the save button bar (accessory part) (MB-1800, MB-1800B) ...................................... 19

13. Adjusting the wiper (Optional for MB-1800) ................................................................................. 19

&. ATTACHMENTS ..............................................................................................20

1. Attachment for shank buttons (pearl buttons) (14617658, 14617757)........................................ 21

2. Attachment for the first process of wrapped-around buttons (B24473720A0) ......................... 21

3. Attachment for the second process of wrapped-around buttons (MAZ046010A0) .................. 22

4. Attachment for snap (14617955) .................................................................................................... 22

5. Attachment for metal buttons (14618052) ..................................................................................... 23

*.ERROR LIST ....................................................................................................24

(.TROUBLES AND CORRECTIVE MEASURES ............................................... 25

). OPTIONAL .......................................................................................................26

1. Installing the without-crossover-thread device (Part No. : M85126300A0)................................ 26

_.DRAWING OF THE TABLE ............................................................................. 27