4. ADJUSTING THE SEWING MACHINE ......................................................................... 24

4-1. Thread tension................................................................................................................... 24

4-1-1. Adjusting the needle thread tension .....................................................................................24

4-1-2. Adjusting the bobbin thread tension ..................................................................................... 24

4-2. Thread take-up spring....................................................................................................... 24

4-2-1. Adjusting the thread take-up spring strength.......................................................................24

4-2-2. Adjusting the thread take-up amount of the thread take-up spring.................................... 24

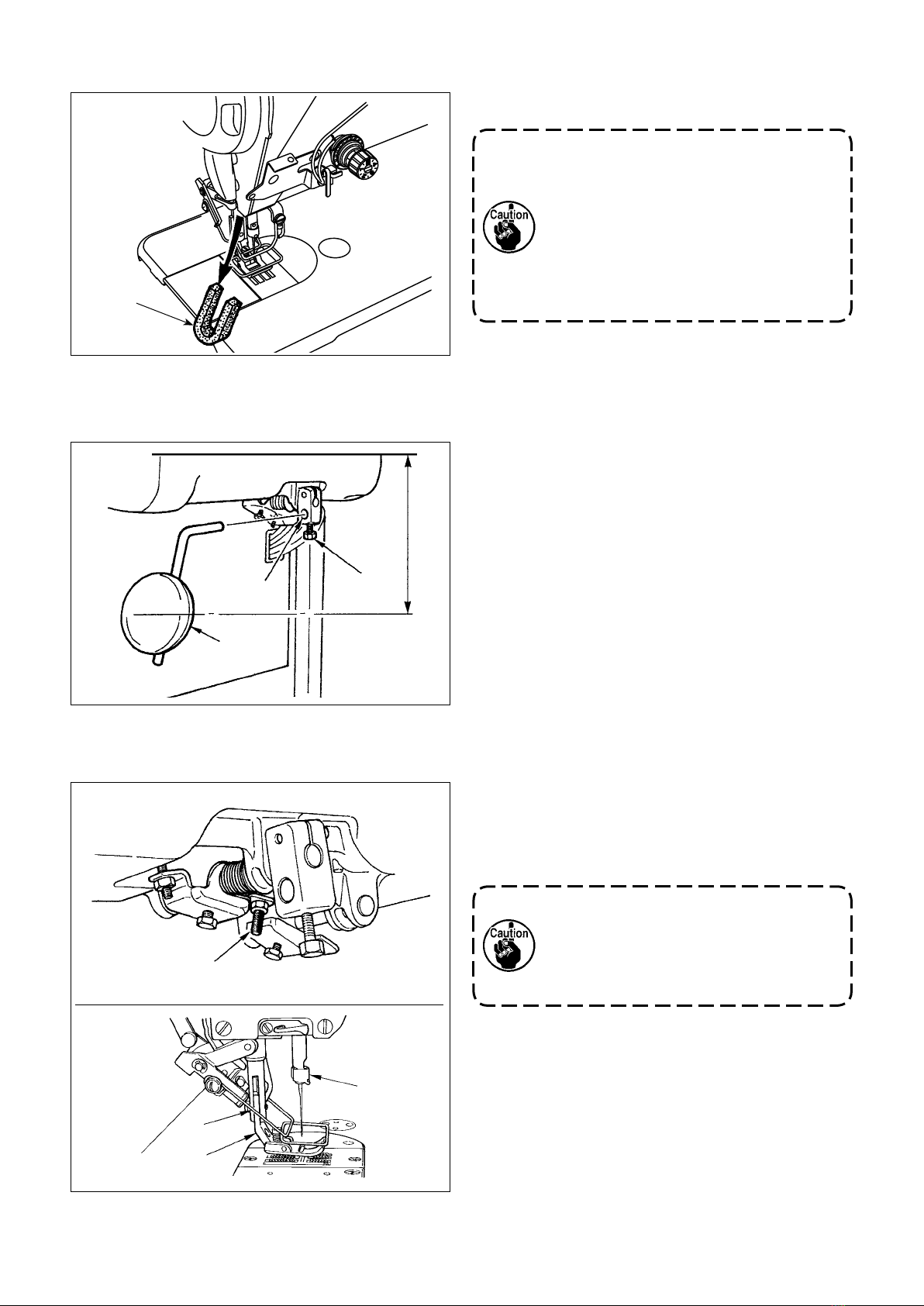

4-3. Presser foot........................................................................................................................ 25

4-3-1. Adjusting the pressure of the presser foot ........................................................................... 25

4-3-2. Adjusting the height of the presser bar.................................................................................25

4-3-3. Micro-lifting mechanism of the presser foot ........................................................................25

4-4. Adjusting the stitch length ............................................................................................... 26

4-5. Changing the sewing speed ............................................................................................. 26

4-6. LED hand light ................................................................................................................... 27

4-7. Reverse feed stitching ...................................................................................................... 27

4-8. Custom switch ................................................................................................................... 28

4-9. Mirror stitching .................................................................................................................. 30

4-10. Fagot stitch ...................................................................................................................... 32

4-11. Adjusting the amount of oil in the hook ....................................................................... 33

5. HOW TO USE THE OPERATION PANEL ..................................................................... 34

5-1. Explanation of the sewing screen (when selecting a sewing pattern) ......................... 34

5-2. Sewing patterns................................................................................................................. 38

5-2-1. Sewing pattern conguration ................................................................................................. 38

5-2-2. List of sewing patterns............................................................................................................ 39

5-2-3. Reverse feed stitching (at start) pattern ................................................................................41

5-2-4. Reverse feed stitching (at end) pattern .................................................................................46

5-2-5. Editing the sewing patterns ....................................................................................................47

5-2-6. List of pattern functions.......................................................................................................... 50

5-2-7. Teaching function ....................................................................................................................60

5-2-8. One-touch utility changeover function ..................................................................................62

5-2-9. Registration of a new sewing pattern .................................................................................... 63

5-2-10. Copying a pattern ..................................................................................................................65

5-2-11. Narrow-down function...........................................................................................................66

5-3. Setting of the sewing shape ............................................................................................. 67

5-3-1. 2-step zigzag, 3-step zigzag and 4-step zigzag stitch .......................................................... 67

5-3-2. Scallop stitching ...................................................................................................................... 70

5-3-3. Blind stitch sewing .................................................................................................................. 73

5-3-4. Custom pattern stitching ........................................................................................................74

5-3-5. T stitch, left...............................................................................................................................74

5-3-6. T stitch, right ............................................................................................................................ 76

5-3-7. Pattern 1....................................................................................................................................79

5-3-8. Pattern 2 (fagoting) ..................................................................................................................81

5-3-9. Pattern 3....................................................................................................................................83

5-3-10. Pattern 4..................................................................................................................................85

5-4. Counter function................................................................................................................ 87

5-4-1. Displaying the sewing screen under the counter display mode .........................................87

5-4-2. Types of the counter................................................................................................................ 87

5-4-3. How to set the counter ............................................................................................................ 88

5-4-4. How to reset the count-completion state ..............................................................................91

5-5. Simplied chart of panel displays ................................................................................... 92

ii