i

CONTENTS

!. SPECIFICATIONS ..................................................................................... 1

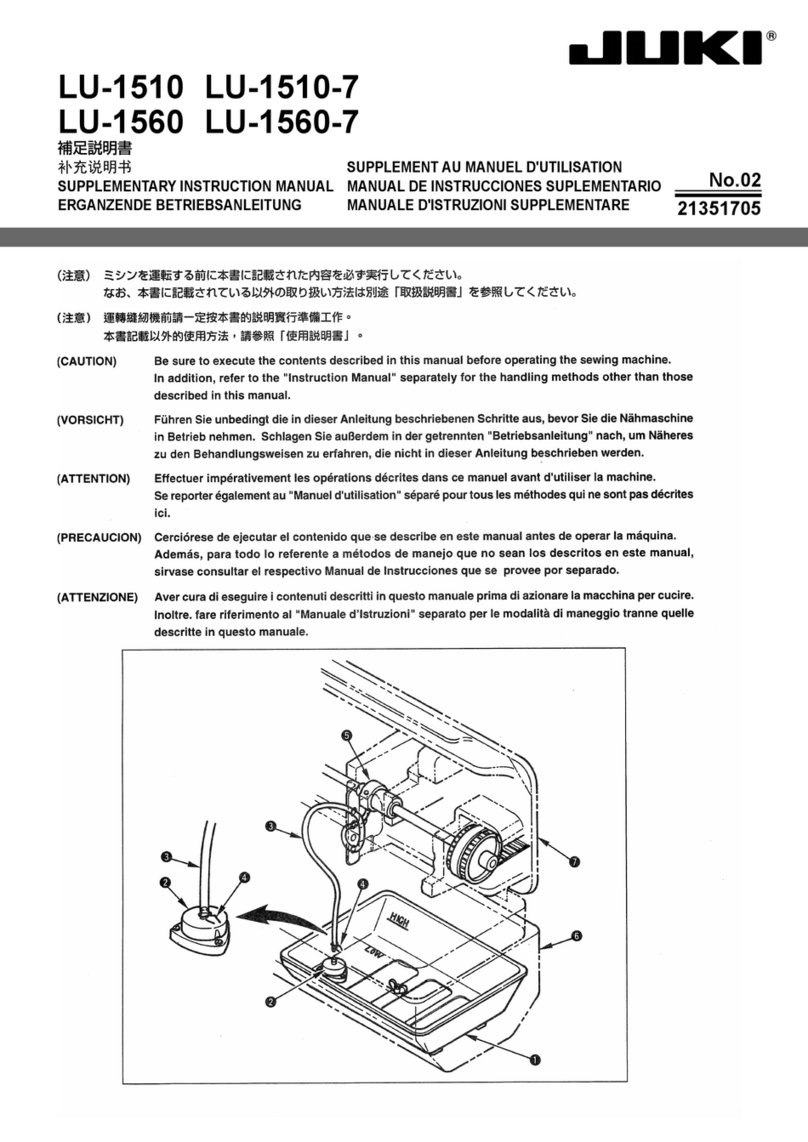

@. SET-UP...................................................................................................... 1

1. Installing to the table..........................................................................................................................1

2. Installing the motor unit.....................................................................................................................2

3. Installing the control box ...................................................................................................................2

4. Installing the belt ................................................................................................................................3

5. Adjusting the pulley cover.................................................................................................................3

6.

Installation and adjustment for the protecting pin and the belt slip-off preventing bracket................... 4

7. Connecting the cords.........................................................................................................................5

8. Attaching the connecting rod..........................................................................................................13

9. Setting procedure of the machine head .........................................................................................14

10. Adjusting the machine head (direct-drive motor type sewing machine only) ............................15

#. FOR THE OPERATOR ............................................................................ 16

1. Operating procedure of the sewing machine.................................................................................16

2. Operation panel (CP-18)...................................................................................................................17

3. Operating procedure of the sewing pattern ................................................................................... 18

(1) Reverse feed stitching pattern ......................................................................................................18

(2) Overlapped stitching pattern......................................................................................................... 19

4. One-touch setting .............................................................................................................................20

5. Production support function ...........................................................................................................22

6. Setting of functions of SC-922 ........................................................................................................25

7. Function setting list..........................................................................................................................27

8. Detailed explanation of selection of functions ..............................................................................33

9. Automatic compensation of neutral point of the pedal sensor ................................................... 47

10.Selectionofthepedalspecications..............................................................................................47

11. Setting of the auto lifter function ....................................................................................................48

12. Selecting procedure of the key-lock function................................................................................49

13. Initialization of the setting data .......................................................................................................49

14. External input / output connector ...................................................................................................50

15. How to connect the material edge sensor......................................................................................51

$. MAINTENANCE ...................................................................................... 52

1. Removing the rear cover.................................................................................................................. 52

2. Replacing the fuse............................................................................................................................52

3. Error codes........................................................................................................................................53