CONTENTS

I. EXPLANATION OF THE LK-1900S,

COMPUTER-CONTROLLED HIGH-

SPEED BARTACKING MACHINE ........1

1. SPECIFICATIONS..............................................1

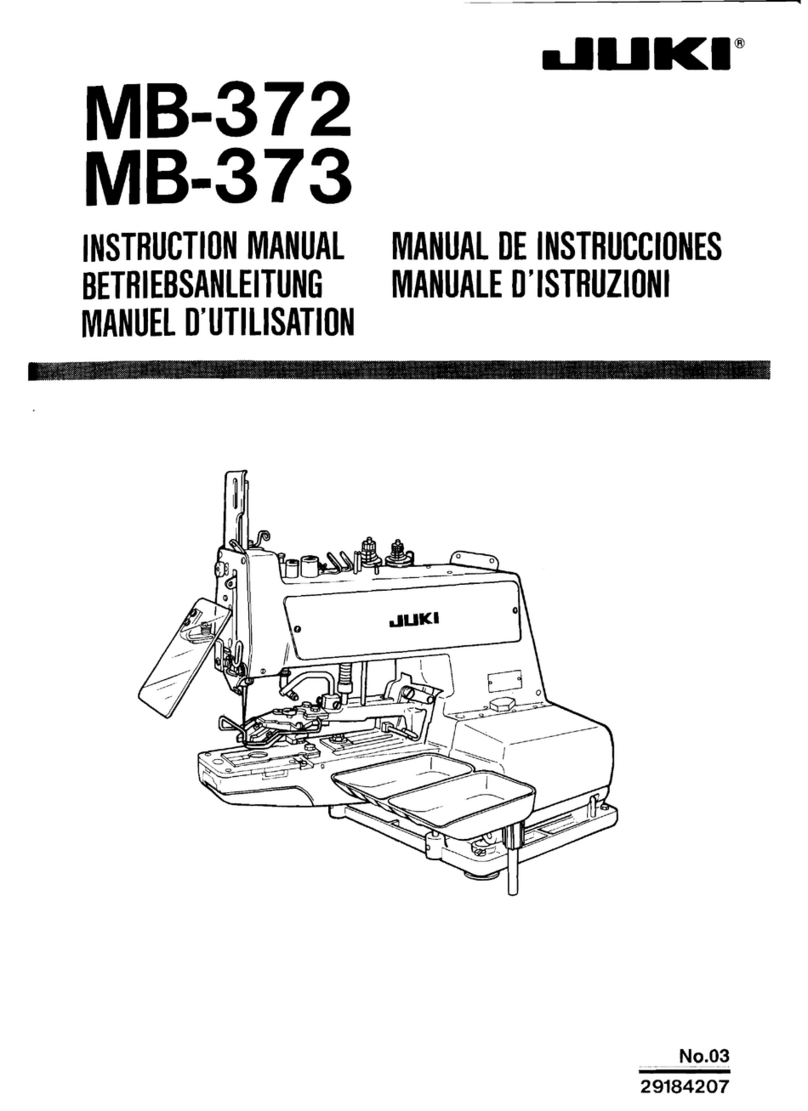

2. CONFIGURATION .............................................2

2-1. Names of main unit ........................................... 2

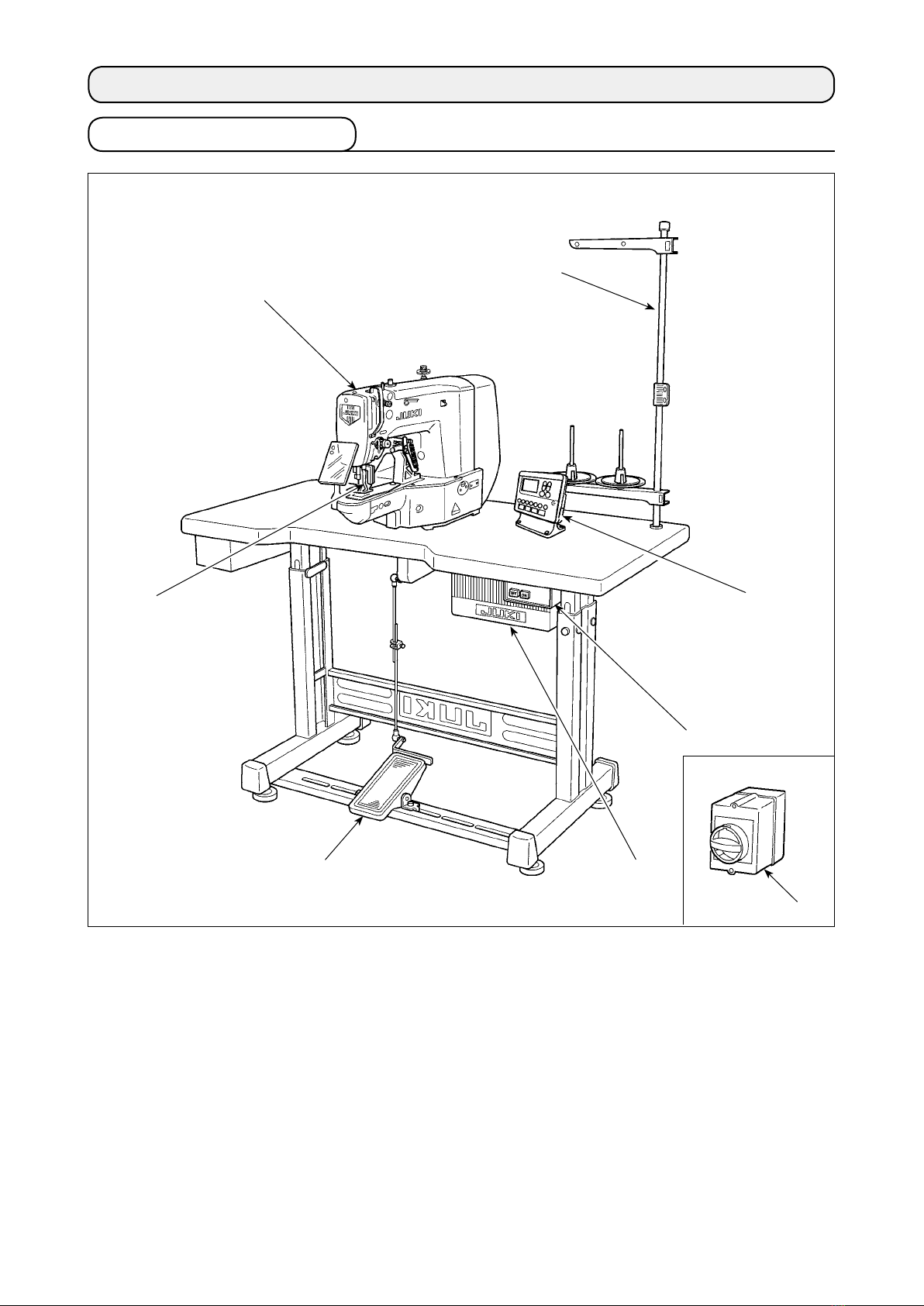

2-2. Names and explanation of switches on the

operation panel.................................................. 3

3. INSTALLATION..................................................4

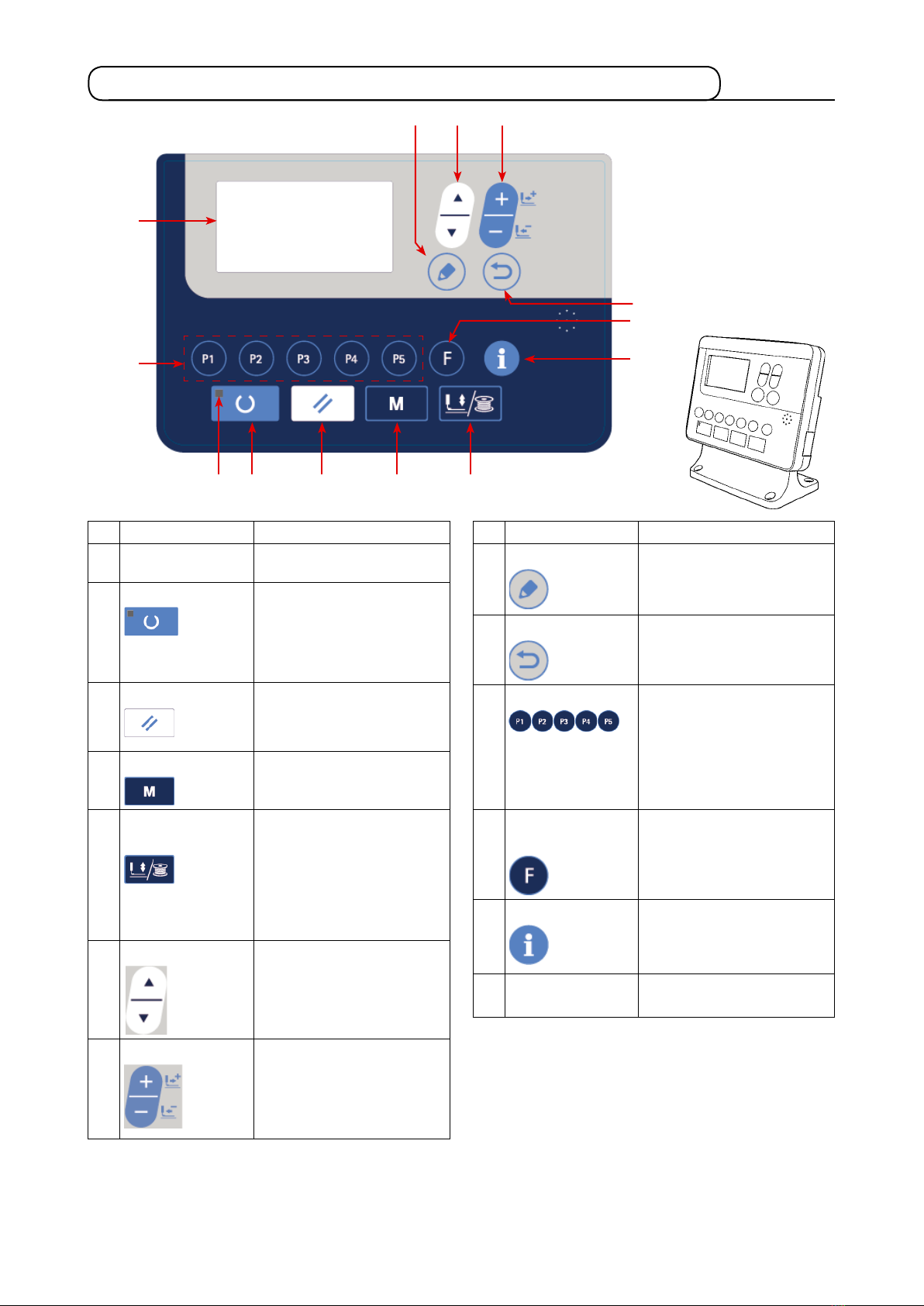

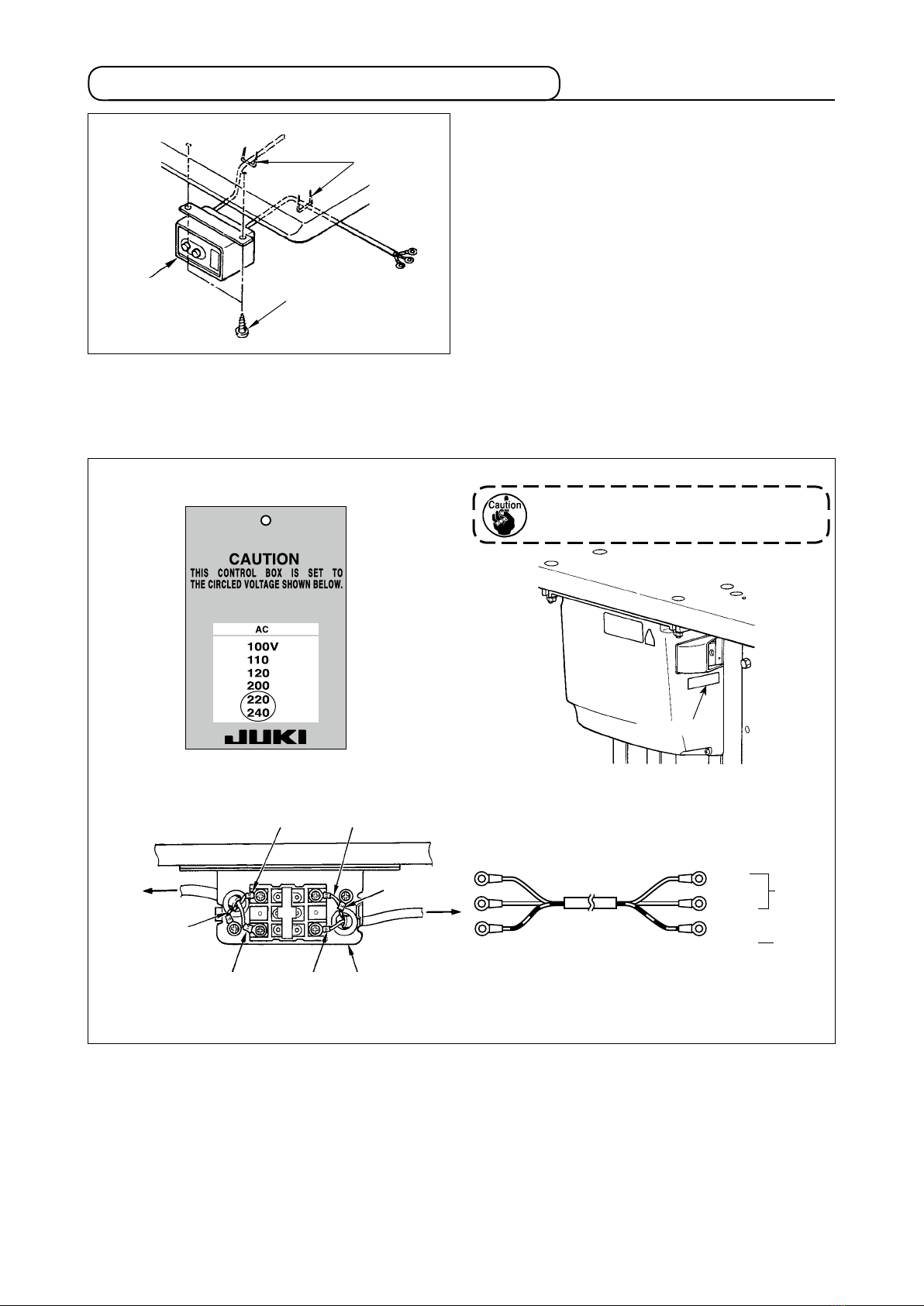

3-1. Installing the electrical box .............................. 4

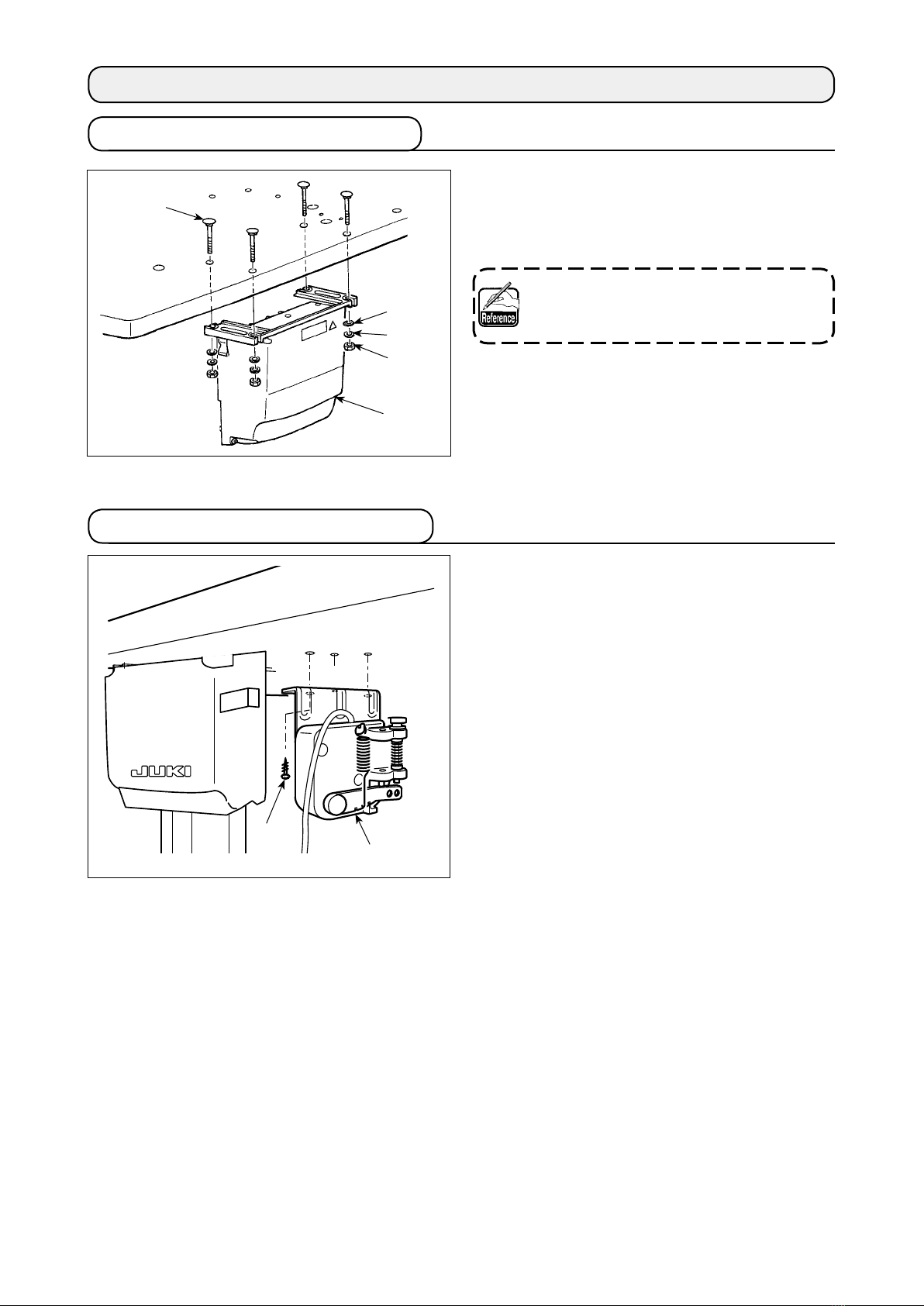

3-2. Installing the pedal sensor ............................... 4

3-3. Attaching the connecting rod........................... 5

3-4. Installing the head support rod........................ 5

3-5. Installing and connecting the power switch... 6

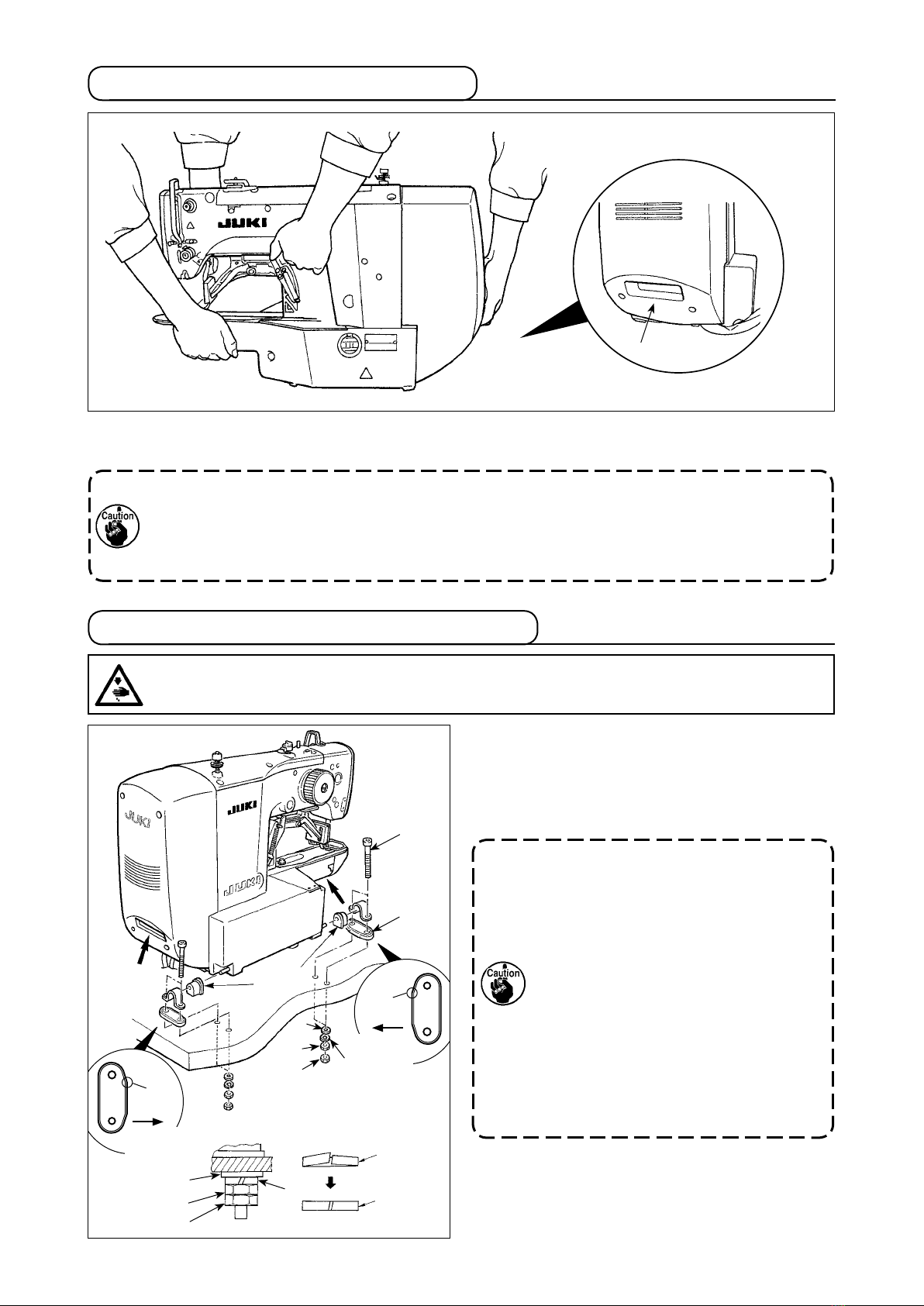

3-6. How to carry the sewing machine.................... 7

3-7. Installation of the sewing machine head......... 7

3-8. Installing the drain receiver and the head

support rubber................................................... 8

3-9. Safety switch...................................................... 8

3-10. Tilting the sewing machine head..................... 9

3-11. Installing the operation panel .......................... 9

3-12. Connecting the cords ..................................... 10

3-13. Handling the cords.......................................... 11

3-14. Installing the eye protection cover................ 12

3-15. Installing the thread stand ............................. 13

3-16. In the case the machine is transported

after factory-completed at the time of

shipment .......................................................... 13

4. OPERATION OF THE SEWING MACHINE.....14

4-1. Lubrication....................................................... 14

4-2. Attaching the needle ....................................... 14

4-3. Threading the machine head.......................... 15

4-4. Installing and removing the bobbin case...... 15

4-5. Installing the bobbin ....................................... 16

4-6. Adjusting the thread tension.......................... 16

4-7. Adjusting the thread take-up spring.............. 17

5. OPERATION OF THE SEWING MACHINE

(BASIC)............................................................17

5-1. Selection of language ..................................... 17

5-2. Setting the pattern number............................. 18

5-3. Setting the item data ....................................... 18

5-4. Checking the contour of a sewing pattern.... 21

5-5. Sewing.............................................................. 22

5-6. Changing the pattern to a different one ........ 22

5-7. Winding a bobbin ............................................ 23

5-8. How to open the tension disk......................... 24

5-9. LED hand light ................................................. 25

6. OPERATION OF THE SEWING MACHINE

(ADVANCED)...................................................26

6-1. Performing sewing using the pattern keys .. 26

6-2. Sewing using the combination function

(cycle sewing).................................................. 31

6-3. Sewing through the use of the counter......... 34

6-4. How to use the temporary stop...................... 37

6-5. Copying or deleting various kinds of

pattern data...................................................... 38

6-6. Communication ............................................... 40

6-7. Cautions in operation...................................... 42

6-8. Setting enable/disable of standard pattern

invoking............................................................ 43

6-9. How to use the F key....................................... 44

6-10. Production support function........................ 45

7. MAINTENANCE...............................................51

7-1. Adjusting the height of the needle bar.......... 51

7-2. Adjusting the needle-to-shuttle relation........ 52

7-3. Adjusting the lift of the work clamp foot....... 53

7-4. The moving knife and counter knife.............. 53

7-5. Adjustment of the wiper.................................. 54

7-6. Draining waste oil............................................ 54

7-7. Amount of oil supplied to the hook ............... 55

7-8. Replacing the fuse........................................... 55

7-9. Replenishing the designated places with

grease............................................................... 56

8. HOW TO USE THE MEMORY SWITCH.........58

8-1. Method of changing memory switch data..... 58

8-2. List of the memory switch functions............. 59

9. OTHERS ..........................................................62

9-1. Table of the standard pattern specications 62

9-2. Table of the standard patterns ....................... 63

9-3. Table of the work clamp foot .......................... 65

9-4. Installing the foot pedal switch (optional)..... 67

9-5. Error list............................................................ 68

9-6. Message list ..................................................... 72

9-7. Troubles and corrective measures (sewing

conditions) ....................................................... 74

9-8. Table of the optional parts.............................. 76

II. EXPLANATION OF THE LK-1903S,

COMPUTER-CONTROLLED HIGH-

SPEED LOCKSTITCH BUTTON

SEWING MACHINE.............................78

1. SPECIFICATIONS............................................78

2. PREPARATION OF THE SEWING MACHINE 78

2-1. Installation of the sewing machine and

preparation of the operation .......................... 78

2-2. Needle and thread ........................................... 78

2-3. Various sewing modes.................................... 79

3. ADJUSTMENT OF THE SEWING MACHINE .80

3-1. Position of the button clamp jaw lever.......... 80

3-2. Adjusting the feed plate.................................. 81

3-3. Adjusting the button clamp jaw lever............ 82

3-4. Adjusting the lifting amount of the button

clamp................................................................ 82

3-5. Adjustment of the pressure of the work

clamp unit ........................................................ 83

3-6. Adjustment of the wiper spring...................... 83

4. OTHERS ..........................................................84

4-1. Installing the save button bar (accessory

part) .................................................................. 84

4-2. Model classication according to the

button size ....................................................... 84

4-3. Attaching the shank button (optional)........... 85

III. DRAWING OF THE TABLE ................89