CONTENTS

I. SPECIFICATIONS......................................................................................................................1

1. Specications ................................................................................................................................................ 1

2. Modelclassicationaccordingtothebuttonsize ..................................................................................... 2

3. Shapeofbuttons ........................................................................................................................................... 2

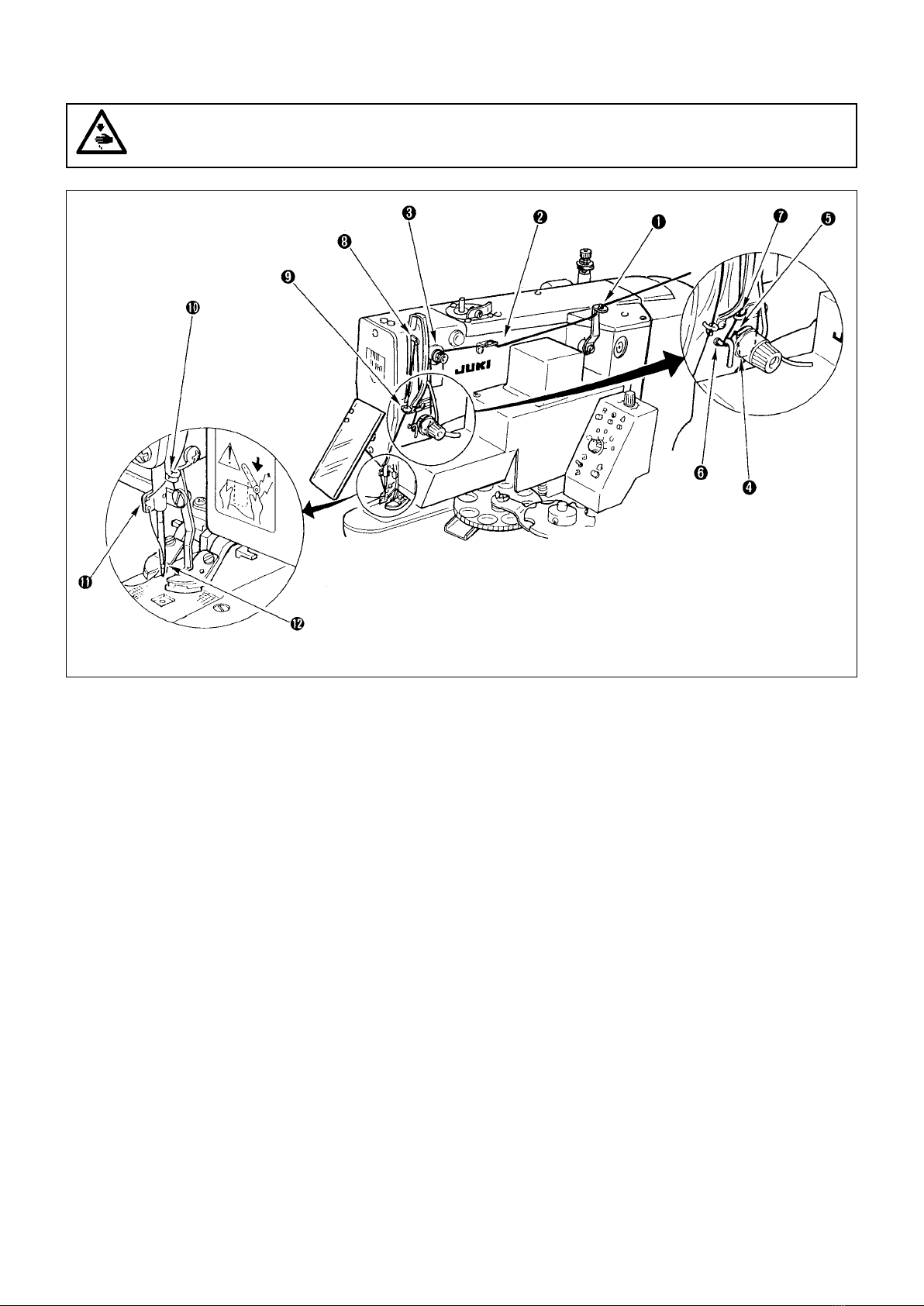

II. NAME OF EACH COMPONENT ..............................................................................................3

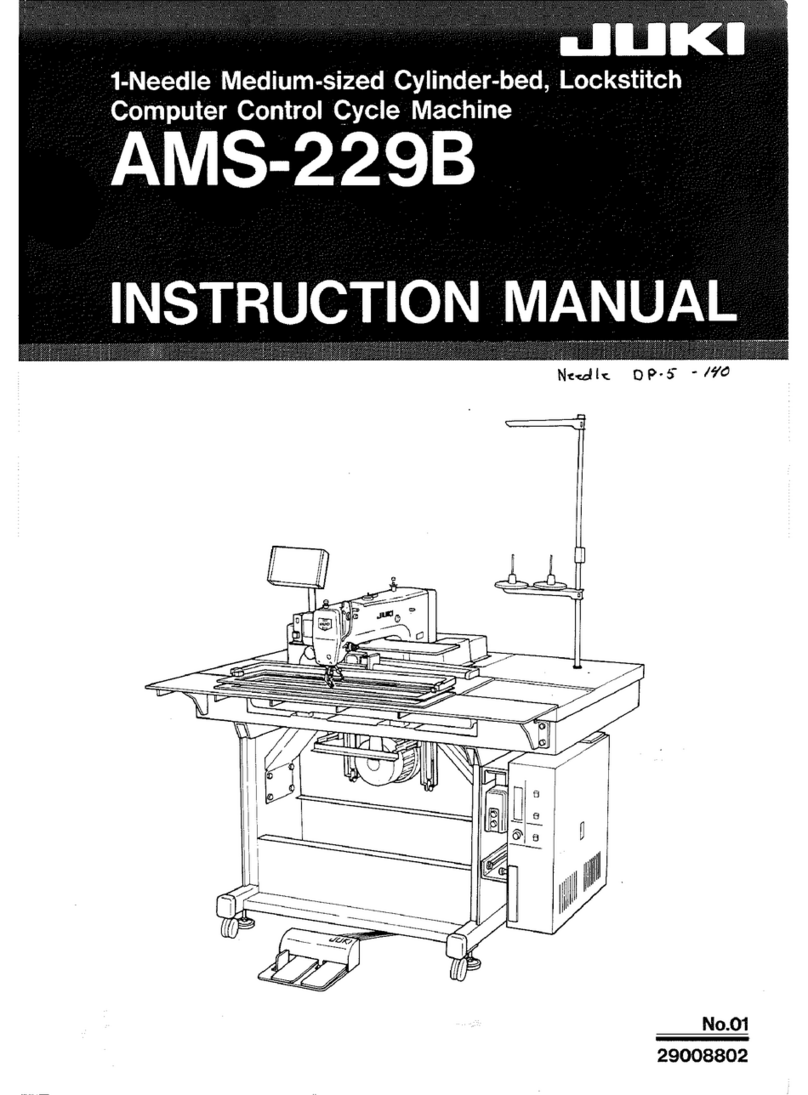

III. INSTALLATION OF THE SEWING MACHINE AND PREPARATION OF THE OPERATION 4

1. Installationofthetableandstand ............................................................................................................... 4

2. Needleandthread ......................................................................................................................................... 4

3. Attachingtheneedle ..................................................................................................................................... 4

4. Threadingthemachine ................................................................................................................................. 5

IV. OPERATION ............................................................................................................................6

1. Operationofthesewingmachine ................................................................................................................ 6

2. Varioussewingmodes.................................................................................................................................. 6

3. Operationofthebuttonfeederunit ............................................................................................................. 8

4. Operation...................................................................................................................................................... 10

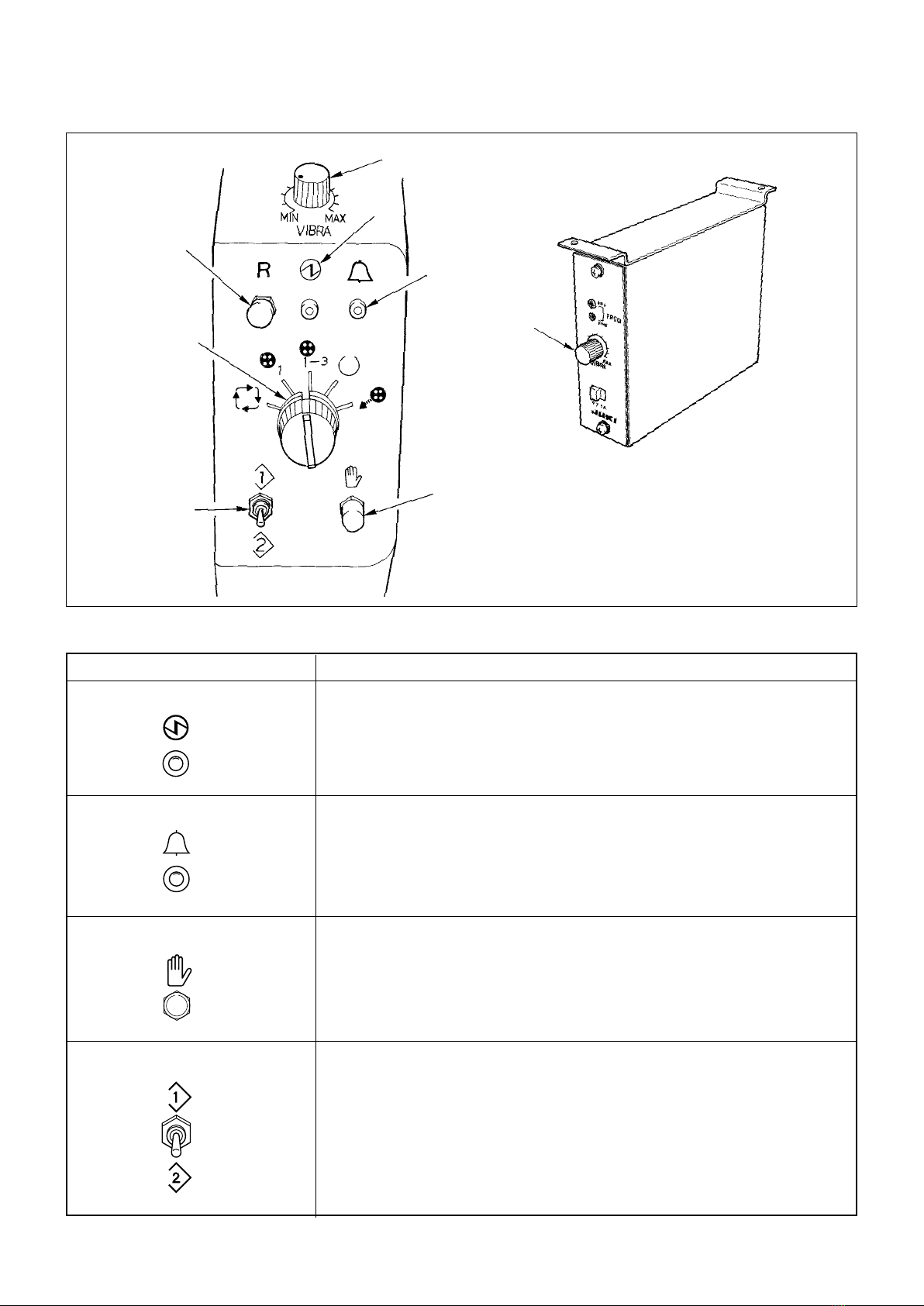

5. HowtosettheDIPswitchesandthedigitalswitches ............................................................................. 10

V. MAINTENANCE......................................................................................................................16

1. Tiltingthesewingmachinehead ............................................................................................................... 16

2. Positionofthebuttonclampjawlever...................................................................................................... 17

3. Adjustingthefeedplate.............................................................................................................................. 18

4. Adjustingthebuttonclampjawlever........................................................................................................ 18

5. Adjustingtheliftingamountofthebuttonclamp .................................................................................... 19

6. Adjustmentofthepressureoftheworkclampunit................................................................................. 20

7. Adjustmentofthewiper.............................................................................................................................. 20

8. Adjustmentofthewiperspring.................................................................................................................. 20

9. Installingthesavebuttonbar(accessorypart)........................................................................................ 21

10. Adjustmentofthebuttonfeederunitcontrolbox .................................................................................... 21

11. Detectingmechanismofthebuttonfeedercomponentsandtheadjustment ...................................... 22

12. Adjustingthefeedplateoftheindexunit ................................................................................................. 23

13. Replacingthebuttonfeedercomponentsandpositioningthem ........................................................... 24

14. Adjustingthevibrationofthebuttonfeeder............................................................................................. 25

15. Adjustingthefeederbowlcomponents .................................................................................................... 25

16. Howtoreplacethebuttons(onthebuttonfeederside) .......................................................................... 28

VI.ALARMNO.INDICATION(onthebuttonfeederunit(BR)side).......................................30

VII. TROUBLES AND CORRECTIVE MEASURES IN BR.........................................................31

VIII. OPTIONAL PARTS..............................................................................................................32

1. Kindsofthebuttoncarrier ......................................................................................................................... 32

2. Attachment................................................................................................................................................... 33

3. Others ........................................................................................................................................................... 34