7. MF-7724DU10D60 (4 needles)............................................................................. 77

(1) Specifications . ..................................................................................................................... 77

(2) Needle .................................................................................................................................... 77

(3) Standard adjustments .......................................................................................................... 78

1) Needle mounting.............................................................................................................................78

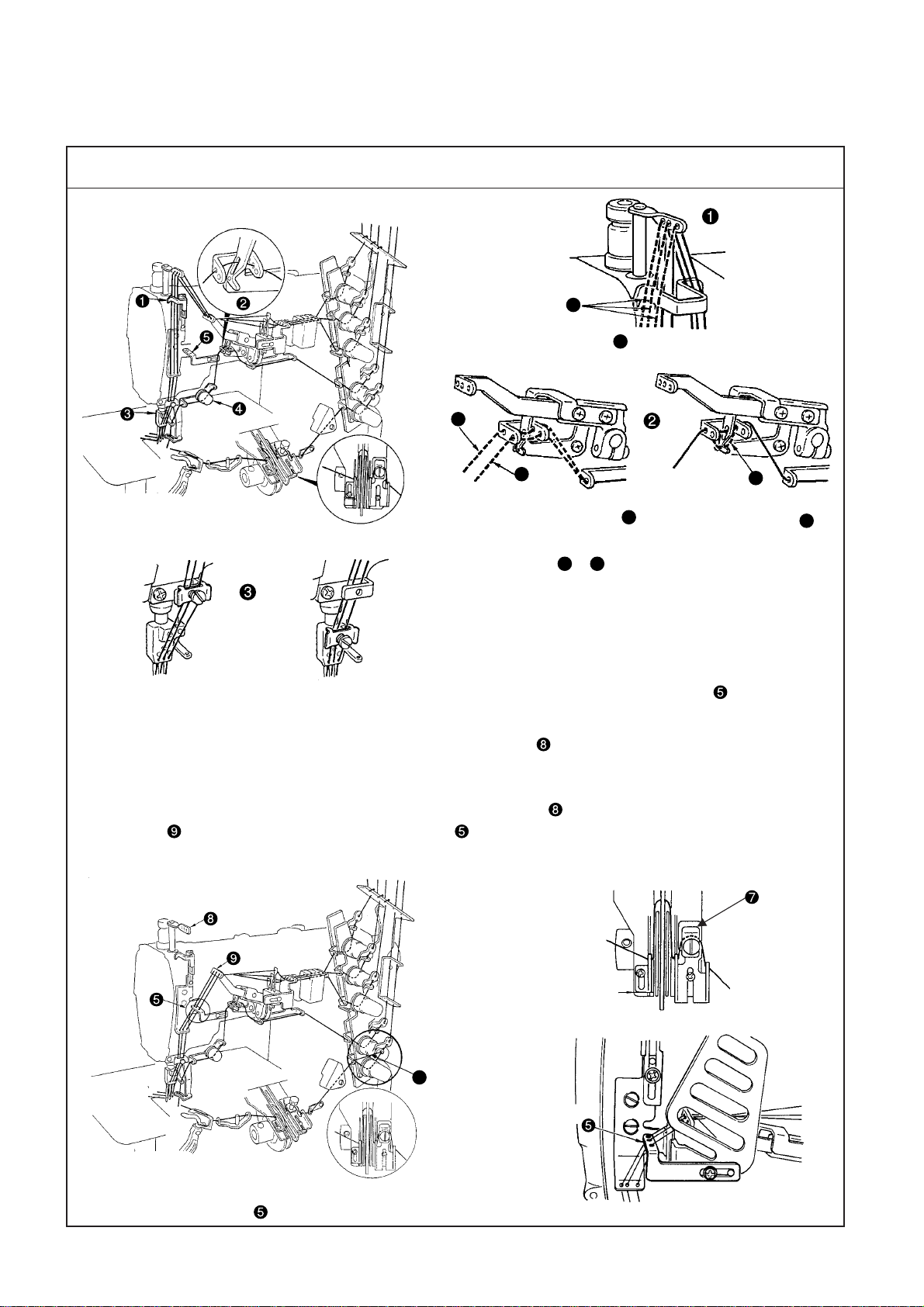

2) Threading the machine head .........................................................................................................80

3) Adjusting the rocking thread take-up ...........................................................................................82

4) Adjusting the position of the needle thread guide rod ...............................................................84

5) Adjusting the rocking thread take-up thread receiver ................................................................86

6) Adjusting the looper.......................................................................................................................88

7) Adjusting the height of the needle................................................................................................88

8) Adjusting the rear needle guard....................................................................................................90

9) Adjusting the looper thread cam...................................................................................................90

10)Installing position of the spreader ................................................................................................92

8. UT31 ...................................................................................................................... 94

(1) Installation of SC-500 ........................................................................................................... 94

(2) Change of the setting ........................................................................................................... 96

(3) Adjusting the synchronizer ................................................................................................. 98

(4) Installation of SC-510 ......................................................................................................... 100

(5) Adjusting the looper thread trimmer mechanism............................................................ 106

9. UT33 .................................................................................................................... 120

(1) Installation of SC-500 ......................................................................................................... 120

(2) Installation of SC-510 ......................................................................................................... 122

(3) Piping of the thread trimmer device ................................................................................. 124

(4) Adjusting the looper thread trimmer mechanism............................................................ 126

(5) Adjusting the top covering thread trimmer mechanism ................................................. 130

(6) Adjusting the air-blow wiper.............................................................................................. 132

10.TC13 (Tape cutter) ............................................................................................. 134

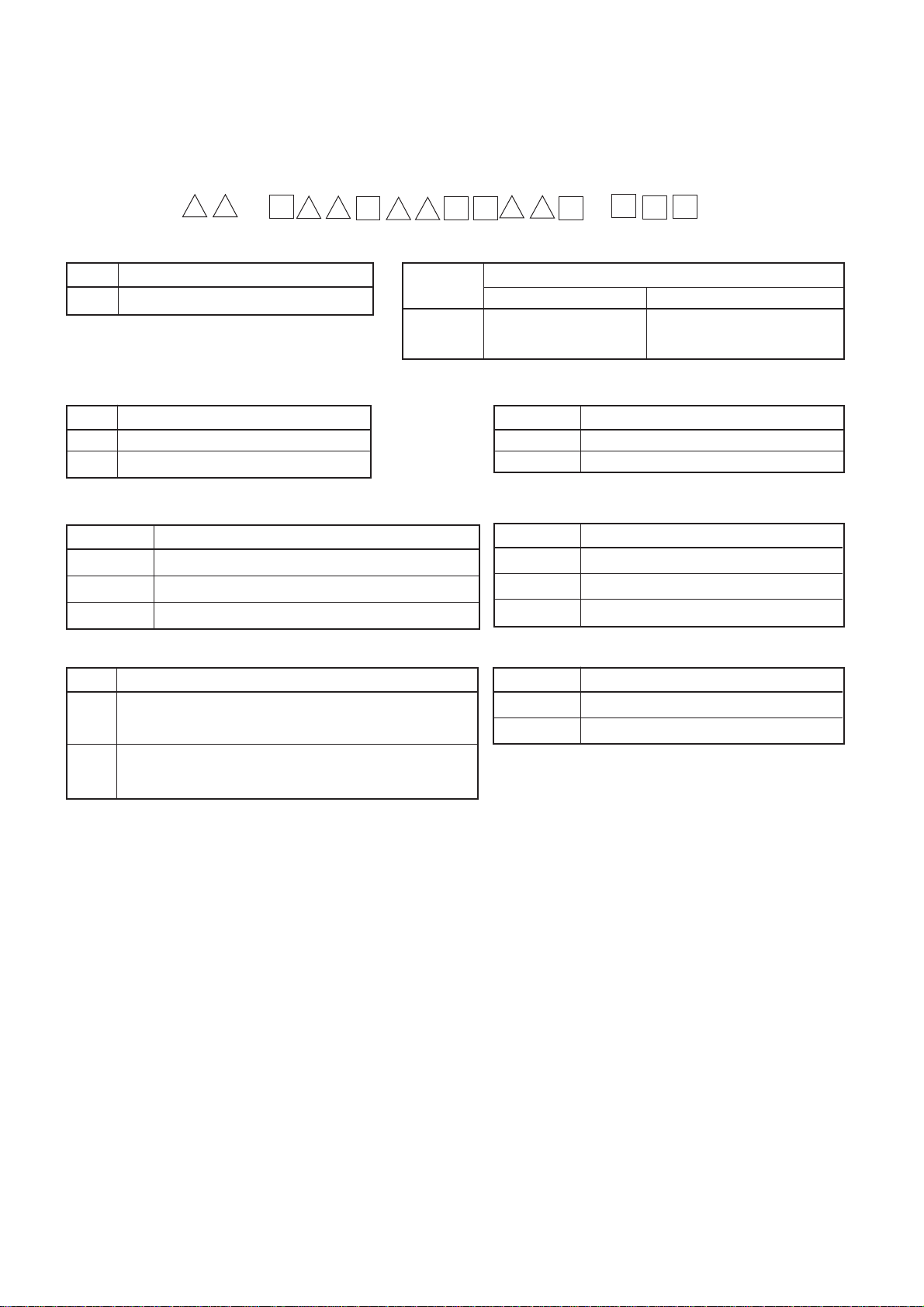

(1) Specifications ..................................................................................................................... 134

(2) Adjustment of knife ............................................................................................................ 136

(3) TC13C .................................................................................................................................. 140

11. OTHER CAUTIONS ............................................................................................ 146

(1) MF-7700D dry section......................................................................................................... 146

(2) Application of appropriate grease .................................................................................... 146

(3) Adhesives application spots ............................................................................................. 148

12.TROUBLES AND CORRECTIVE MEASURES .................................................. 149

13.DRAWING OF TABLE......................................................................................... 163

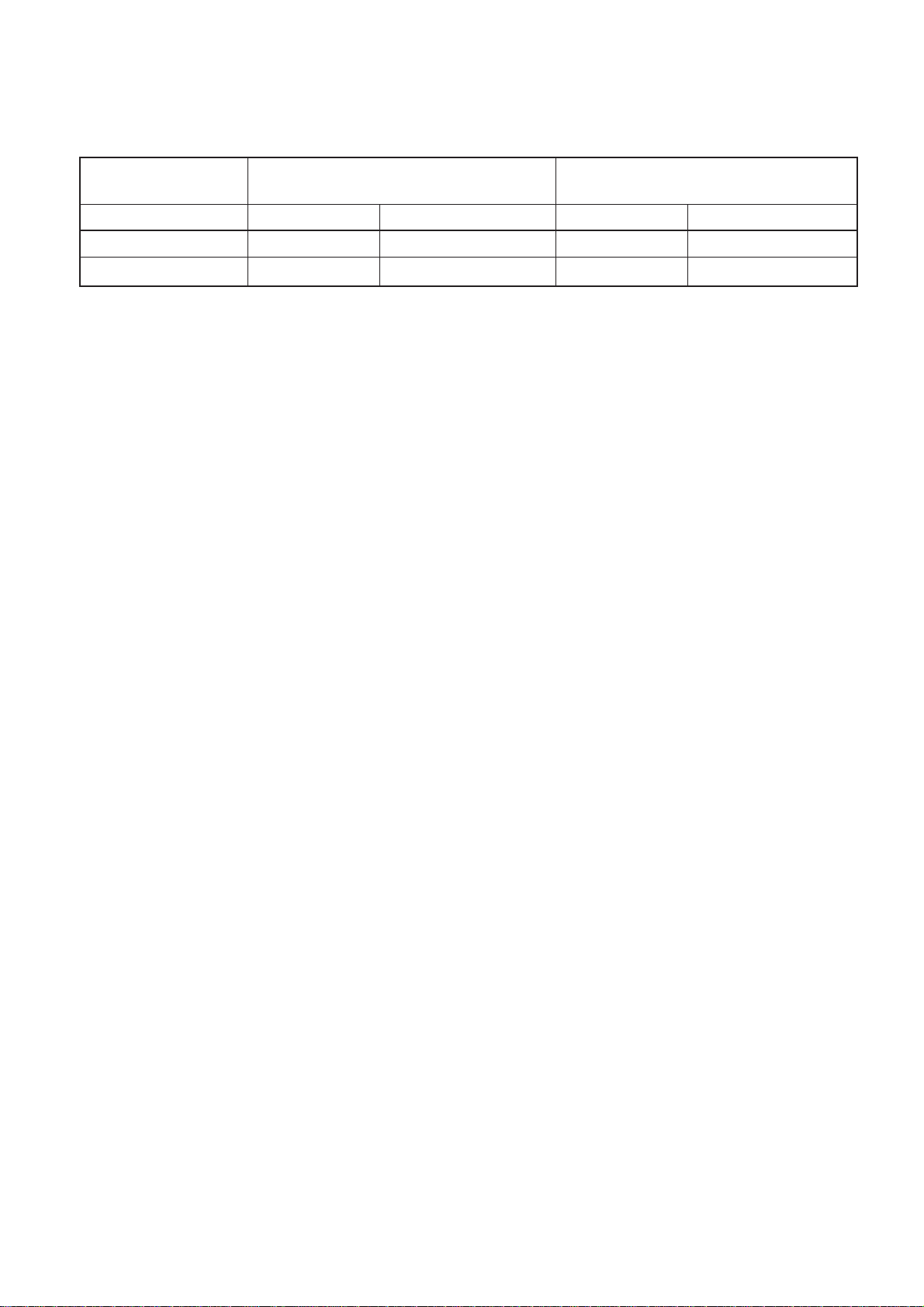

(1) Semi-Submerged Type ....................................................................................................... 163

(2) For MF-7700D/E10 (Semi-Submerged Type) .................................................................... 164