ENGLISH

CONTENTS

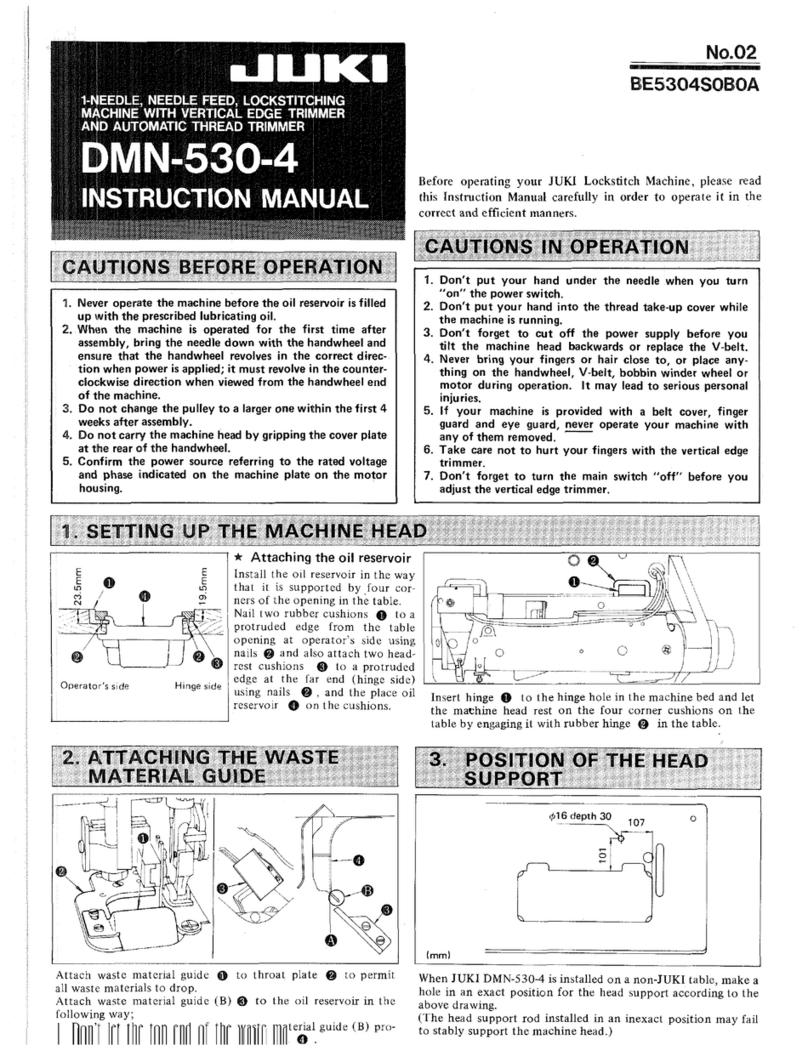

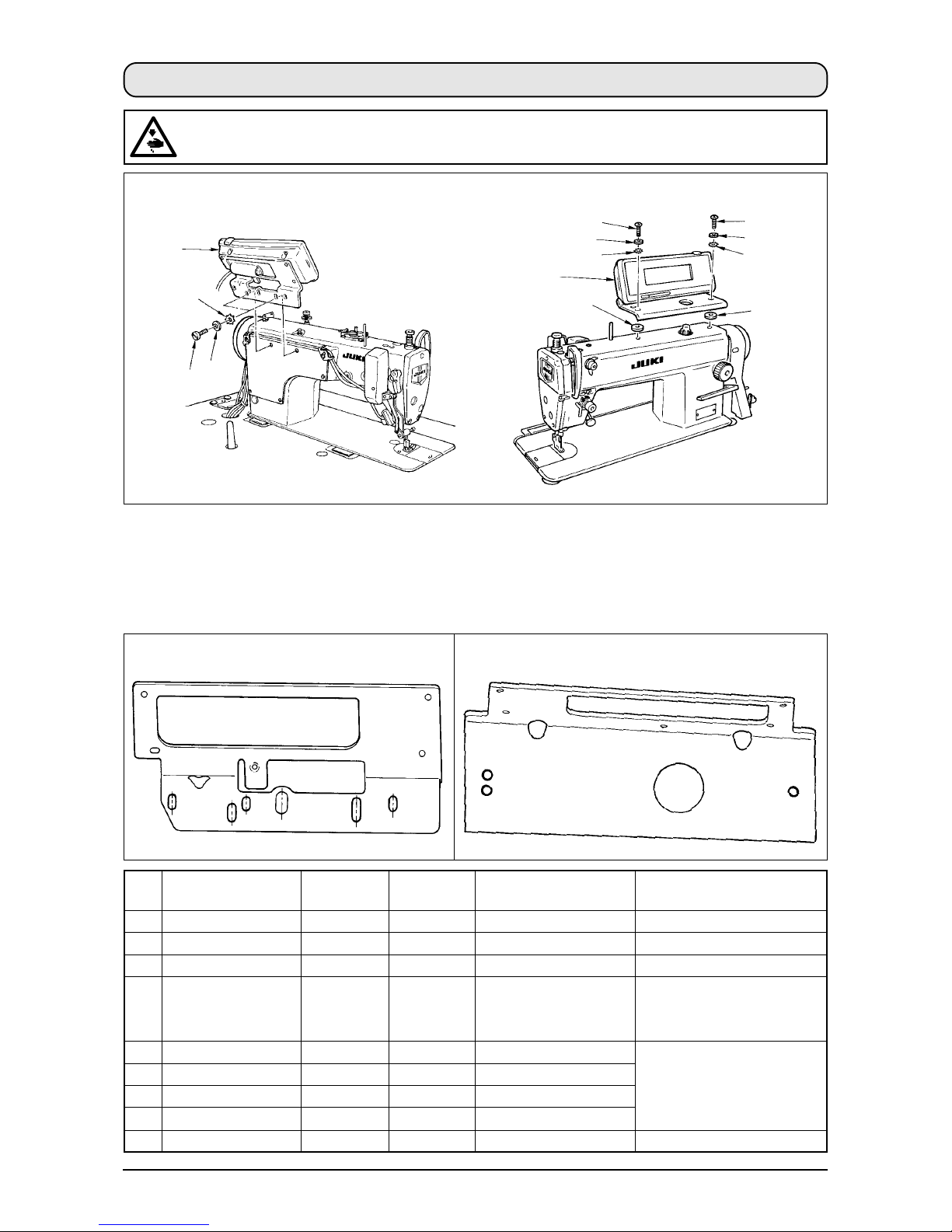

1. INSTALLINGTHE OPERATION PANEL ................................................................... 1

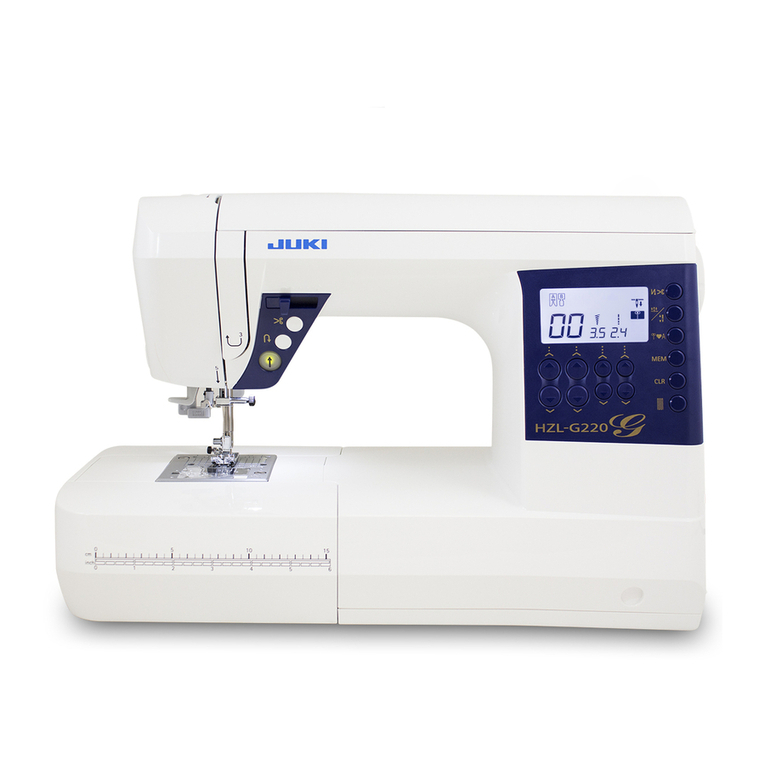

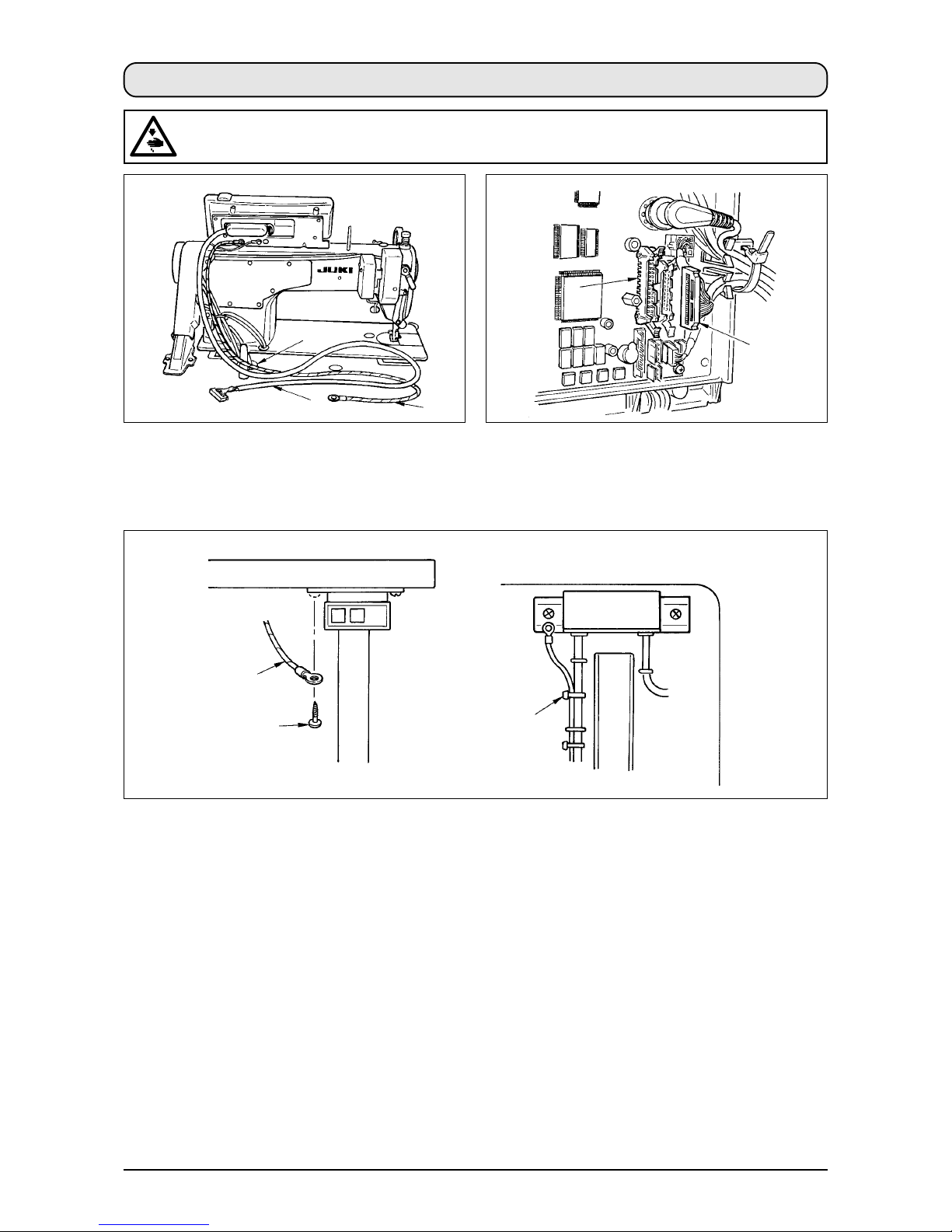

2. CONNECTINGTHE CORD........................................................................................2

3. HOWTO USETHE OPERATION PANEL .................................................................. 3

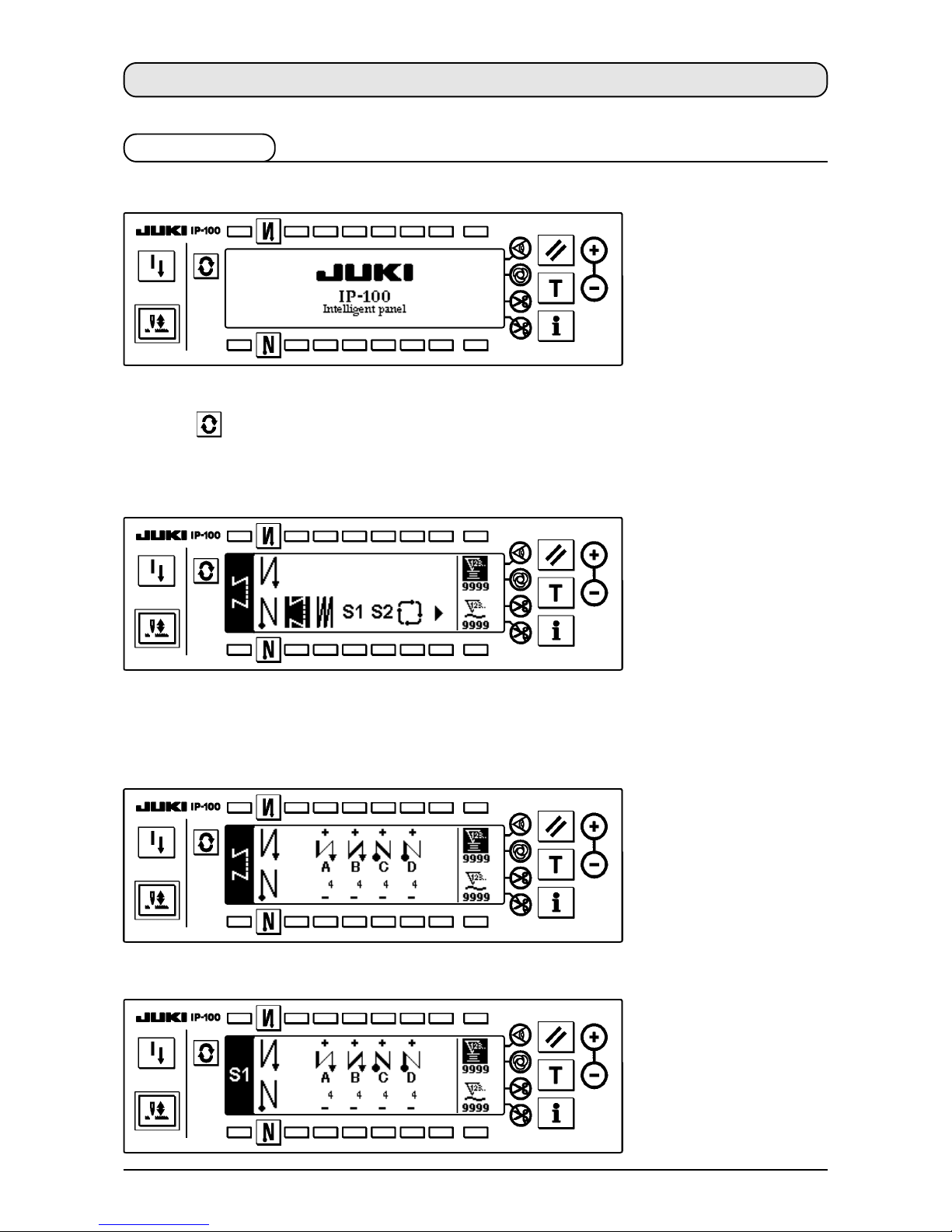

3-1. Names and functions of each components ........................................................................ 3

3-2. Adjusting the contrast of the operation panel display ...................................................... 5

3-3. Production control switch connecting connector.............................................................. 5

4. STANDARD PANEL...................................................................................................6

4-1. Screen list .............................................................................................................................. 6

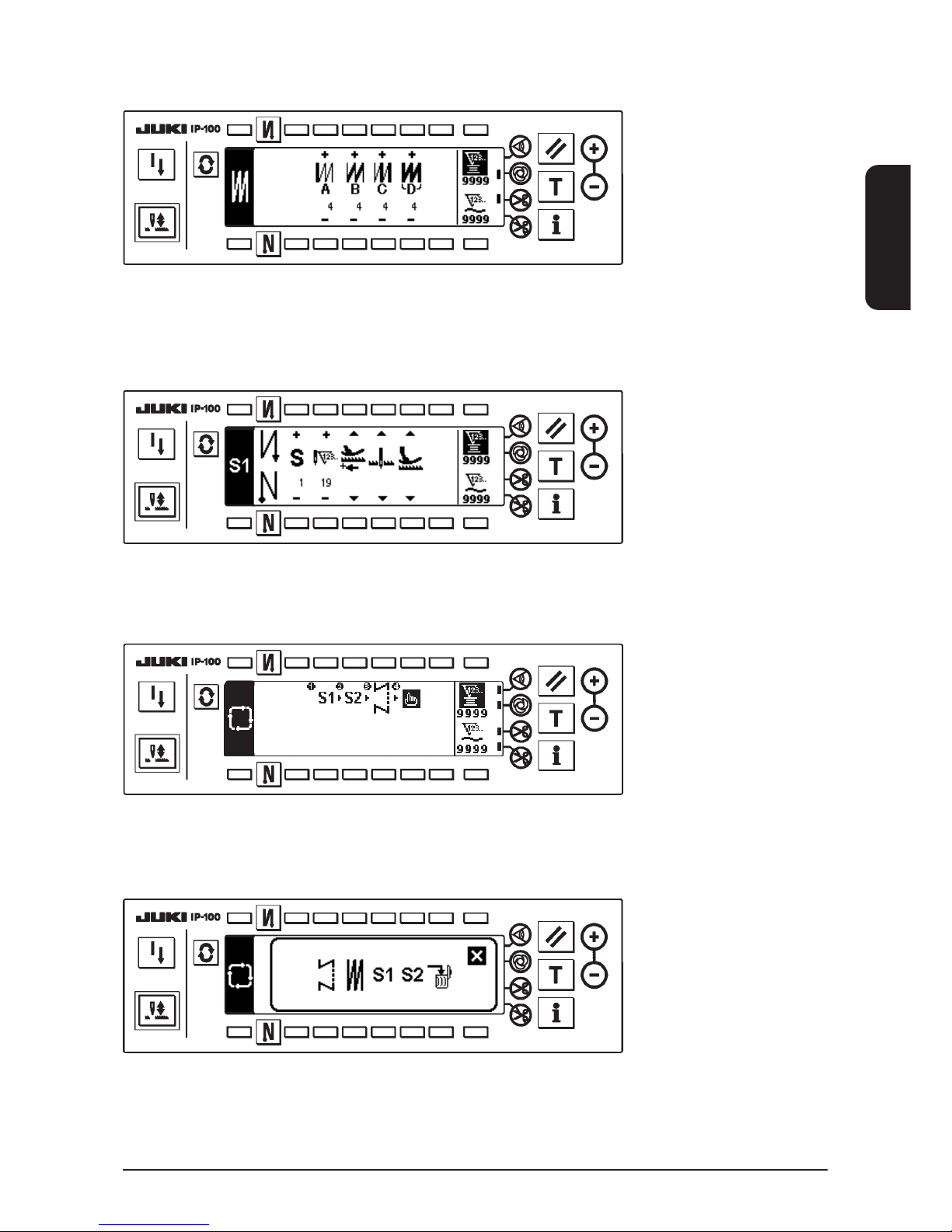

4-2. How to operate the operation panel for sewing stitching patterns .................................. 8

(1) Reverse stitching pattern...................................................................................................................8

(2) Overlapped stitching pattern...........................................................................................................10

(3) Programmed stitching pattern ........................................................................................................11

(4) Cycle sewing pattern........................................................................................................................15

4-3. How to use the bobbin thread counter.............................................................................. 17

4-4. No. of pcs. counter .............................................................................................................. 18

4-5. Re-sewing switch ................................................................................................................ 18

4-6. Needle up/down compensation switch ............................................................................. 19

4-7. ON/OFF switch of the material edge sensor ............................................................... 19

4-8. Automatic thread trimming switch .............................................................................. 19

4-9. One-shot automatic stitching switch ........................................................................... 19

4-10.Thread trimming prohibition switch ........................................................................... 19

4-11. Key lock.............................................................................................................................. 19

4-12. Information......................................................................................................................... 20

(1) Sewing management information ...................................................................................................20

(2) Production control function ............................................................................................................24

(3) Working measurement function ......................................................................................................26

4-13. Setting for functions ......................................................................................................... 28

(1) How to change over to the function setting mode ........................................................................28

(2) Function setting list .........................................................................................................................31

5. PANEL FOR LH-4168/4188..................................................................................... 34

5-1. Screen list ............................................................................................................................ 34

5-2. How to operate the operation panel for sewing stitching patterns ................................ 38

(1) Reverse stitching pattern.................................................................................................................38

(2) Overlapped stitching pattern...........................................................................................................40

(3) Corner pattern...................................................................................................................................41

(4) Step pattern.......................................................................................................................................47

(5) Cycle sewing pattern........................................................................................................................50

5-3. How to use the bobbin thread counter.............................................................................. 51

5-4. No. of pcs. counter .............................................................................................................. 52

5-5. Re-sewing switch ................................................................................................................ 53

5-6. Needle up/down compensation switch ............................................................................. 54

5-7. ON/OFF switch of the material edge sensor ............................................................... 54