i

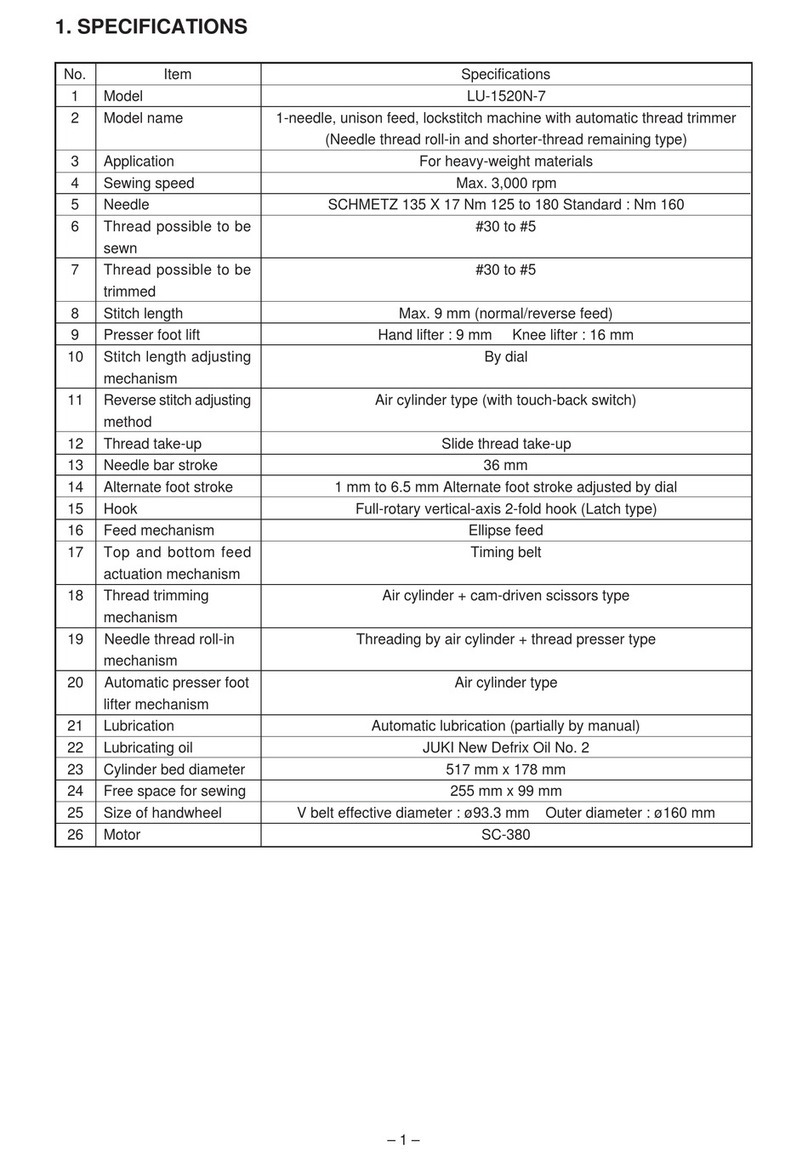

CONTENTS

1. INSTALLING THE OPERATION PANEL.......................................................................1

2. CONNECTING THE CORD ...........................................................................................1

3. MACHINE HEAD SETTINGS ........................................................................................2

4. ADJUSTING THE MACHINE HEAD ANGLE

(DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY).......................................3

5. EXPLANATION OF THE OPERATION PANEL.............................................................4

5-1. Names and functions of each components.................................................................................4

5-2. Adjusting the contrast of the operation panel screen................................................................6

5-3. Connection of the production support switch ............................................................................6

5-4. Basic screen...................................................................................................................................7

5-5. How to operate the operation panel for sewing stitching patterns...........................................9

(1) Reverse stitching pattern...................................................................................................................9

(2) Overlapped stitching pattern ........................................................................................................... 11

(3) Programmed stitching pattern.........................................................................................................12

(4) Cycle sewing pattern ........................................................................................................................16

6. BOBBIN COUNTER ....................................................................................................18

7. NO. OF PCS. COUNTER.............................................................................................19

8. RE-SEWING SWITCH .................................................................................................19

9. NEEDLE UP/DOWN COMPENSATION SWITCH.......................................................20

10. ON/OFF SWITCH OF THE MATERIAL EDGE SENSOR ......................................20

11. AUTOMATIC THREAD TRIMMING SWITCH ........................................................20

12. ONE-SHOT AUTOMATIC STITCHING SWITCH ...................................................20

13. THREAD TRIMMING PROHIBITION SWITCH ......................................................21

14. SIMPLIFIED FUNCTION SETTING.............................................................................22

15. KEY-LOCK FUNCTION SETTING ..............................................................................23

16. FUNCTION SETTING ..................................................................................................24

17. OPTIONAL INPUT/OUTPUT SETTINGS ....................................................................29

18. AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR ....30

19. INITIALIZATION OF THE SETTING DATA .................................................................31

20. INFORMATION ............................................................................................................32

(1) Maintenance management function................................................................................................32

(2) Working measurement function ......................................................................................................36

21. EXTERNAL INTERFACE ............................................................................................38

22. ERROR DISPLAY ........................................................................................................38

22-1. Error code list (Error display in panel).....................................................................................39