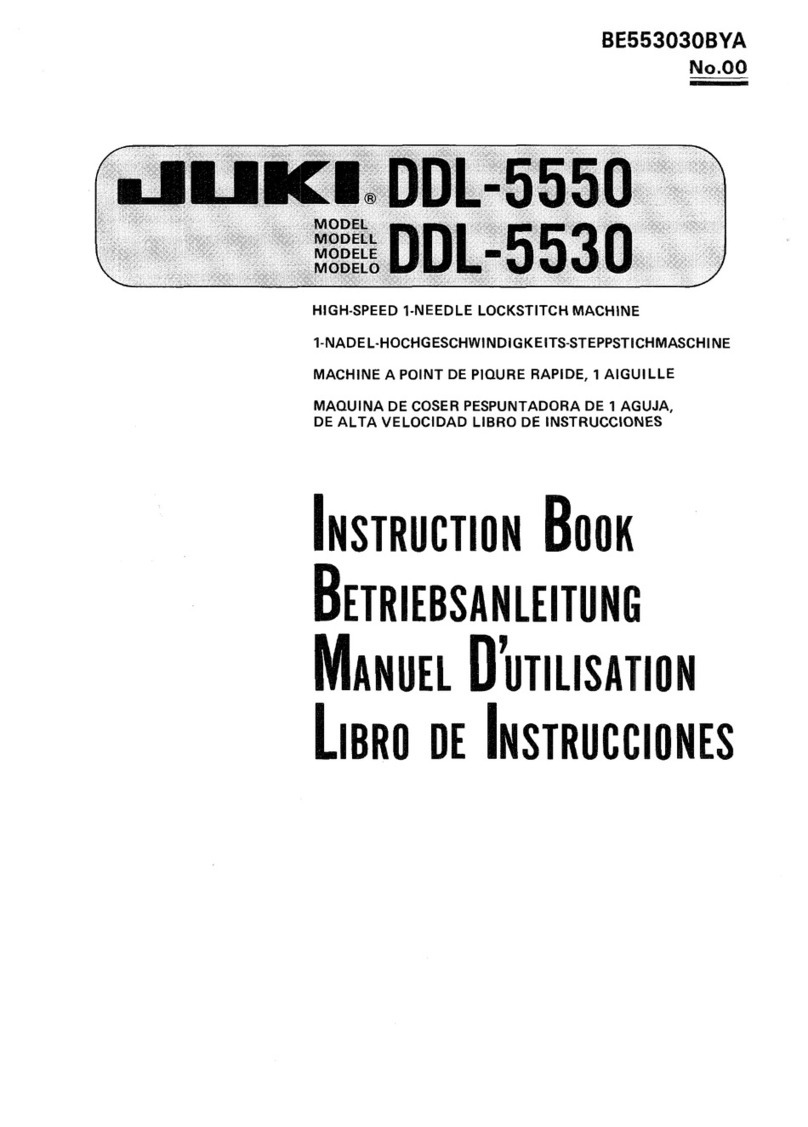

i

CONTENTS

I. MECHANICAL SECTION ........................................................................ 1

1. SPECIFICATIONS..................................................................................................................... 1

2. CONFIGURATION..................................................................................................................... 2

3. INSTALLATION ......................................................................................................................... 3

3-1. Installing the extension plate and the power switch ..................................................................3

3-2. Installing the bobbin winder device .............................................................................................4

3-3. Installing the panel.........................................................................................................................6

3-4. Installing the thread stand ............................................................................................................6

3-5. Installing the X-axis feed mechanism ..........................................................................................7

3-6. Attaching and removing the hook ................................................................................................8

3-7. Installing the auxiliary table..........................................................................................................9

3-8. Installing the air hose ....................................................................................................................9

3-9. Precautions to be taken when installing the machine..............................................................10

3-10. Cautions for the compressed air supply (source of supply air) facility ................................. 11

4. PREPARATION OF THE SEWING MACHINE........................................................................ 12

4-1. Lubricating method and check of the oil quantity....................................................................12

4-2. Attaching the needle....................................................................................................................13

4-3. Threading the machine head ......................................................................................................13

4-4. Bobbin replacement procedure..................................................................................................14

4-5. Adjusting the thread tension ......................................................................................................15

4-6. Adjusting the thread take-up spring and the thread breakage detector plate .......................16

4-7. Adjusting the thread take-up stroke...........................................................................................16

4-8. Needle-to-hook relationship........................................................................................................17

4-9. Adjusting the height of the intermediate presser .....................................................................17

4-10. Adjusting the stroke of the intermediate presser .....................................................................18

4-11. Adjusting the height of disc presser and the presser foot pressure ......................................19

4-12. Adjusting the counter knife.........................................................................................................20

4-13. How to conrm the amount of oil (oil splashes) in the hook...................................................21

4-14. Adjusting the amount of oil in the hook.....................................................................................22

4-15. Direction of rotation of the hand pulley .....................................................................................23

4-16. Installing and adjusting the thread separation plate ................................................................23

4-17. Adjusting the angle of air blower................................................................................................24

5. MAINTENANCE OF SAWING MACHINE............................................................................... 25

5-1. Replenishing the designated places with grease .....................................................................25

5-2. Draining waste oil ........................................................................................................................26

5-3. Use of an air gun..........................................................................................................................27

5-4. Cleaning the hook section ..........................................................................................................27

5-5. Other precautions ........................................................................................................................27

5-6. How to remove the face plate .....................................................................................................28

5-7. Troubles and corrective measures (Sewing conditions)..........................................................29

6. PRECAUTIONS....................................................................................................................... 30

6-1. Standard specication of the templates....................................................................................30

6-2. Sewing with large pitches ...........................................................................................................30

6-3. Reverse feed stitching.................................................................................................................31

6-4. Condensation stitching ...............................................................................................................31

6-5. Groove on the template...............................................................................................................31