i

CoNTENTS

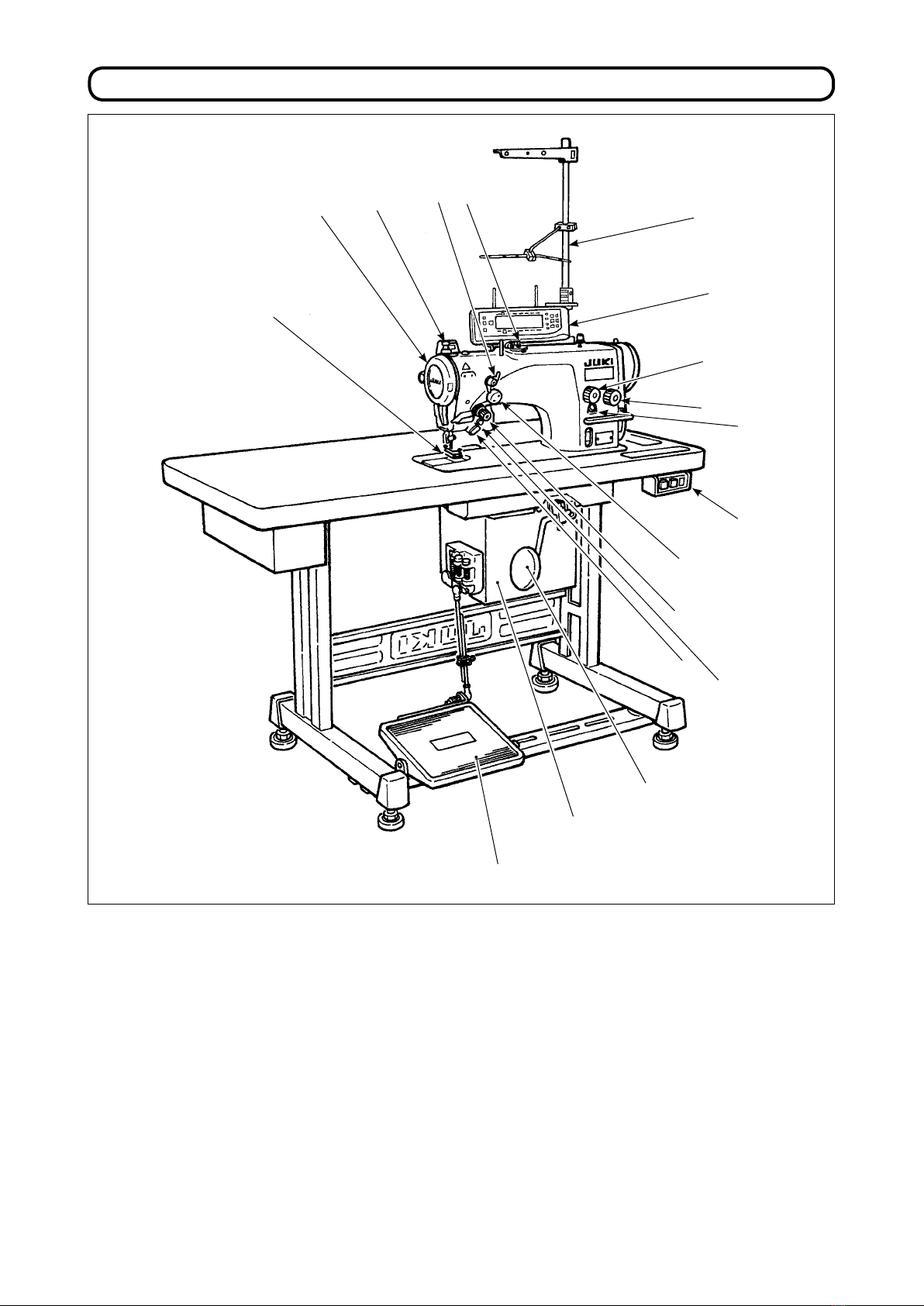

1. NAME oF EACH CoMPoNENT .................................................................................................. 1

2. SPECIFICATIoNS......................................................................................................................... 2

2-1. Specications of the machine head ..................................................................................................2

2-2. Specications of the electrical box ...................................................................................................2

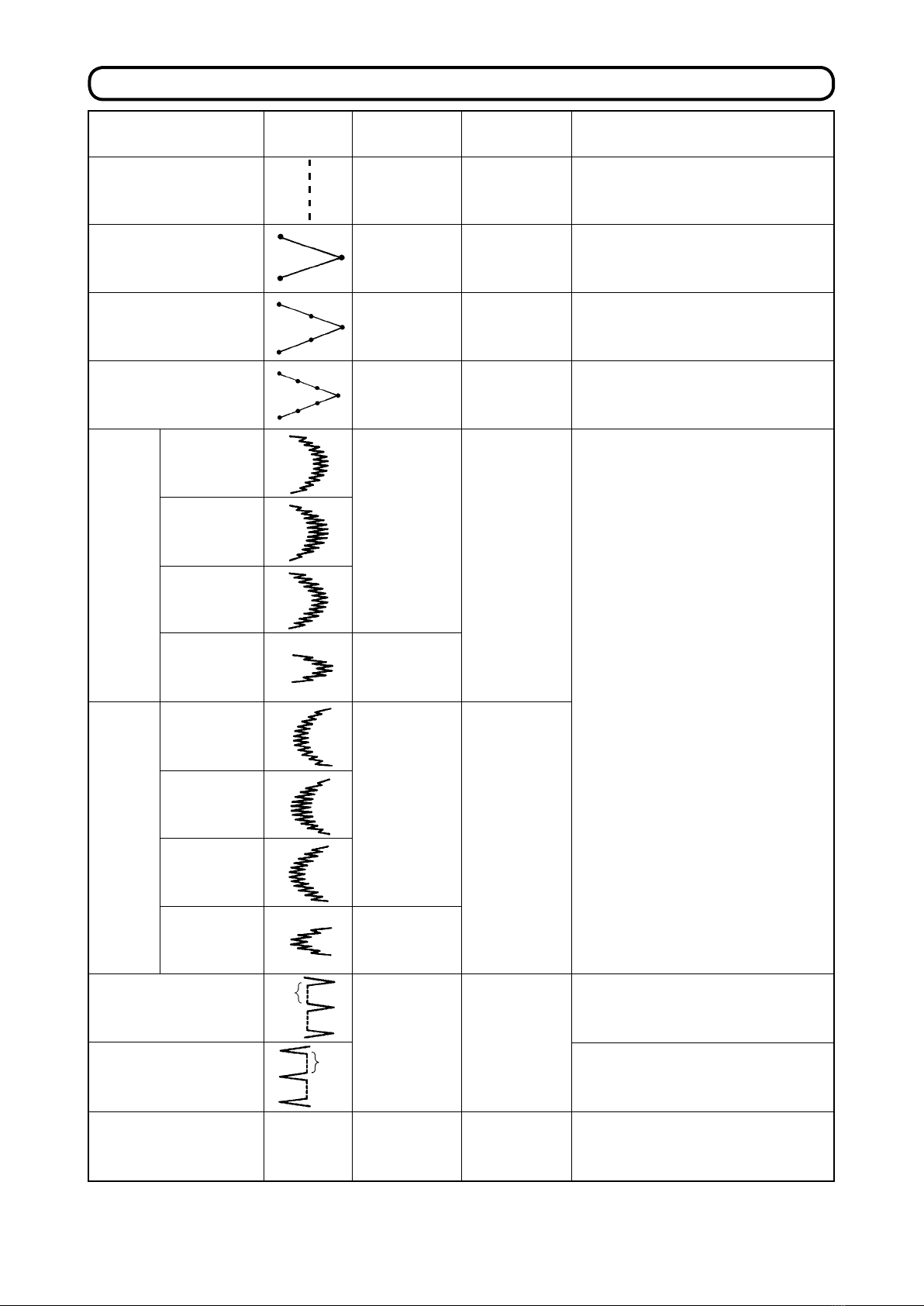

3. STITCH PATTErN TABLE ........................................................................................................... 3

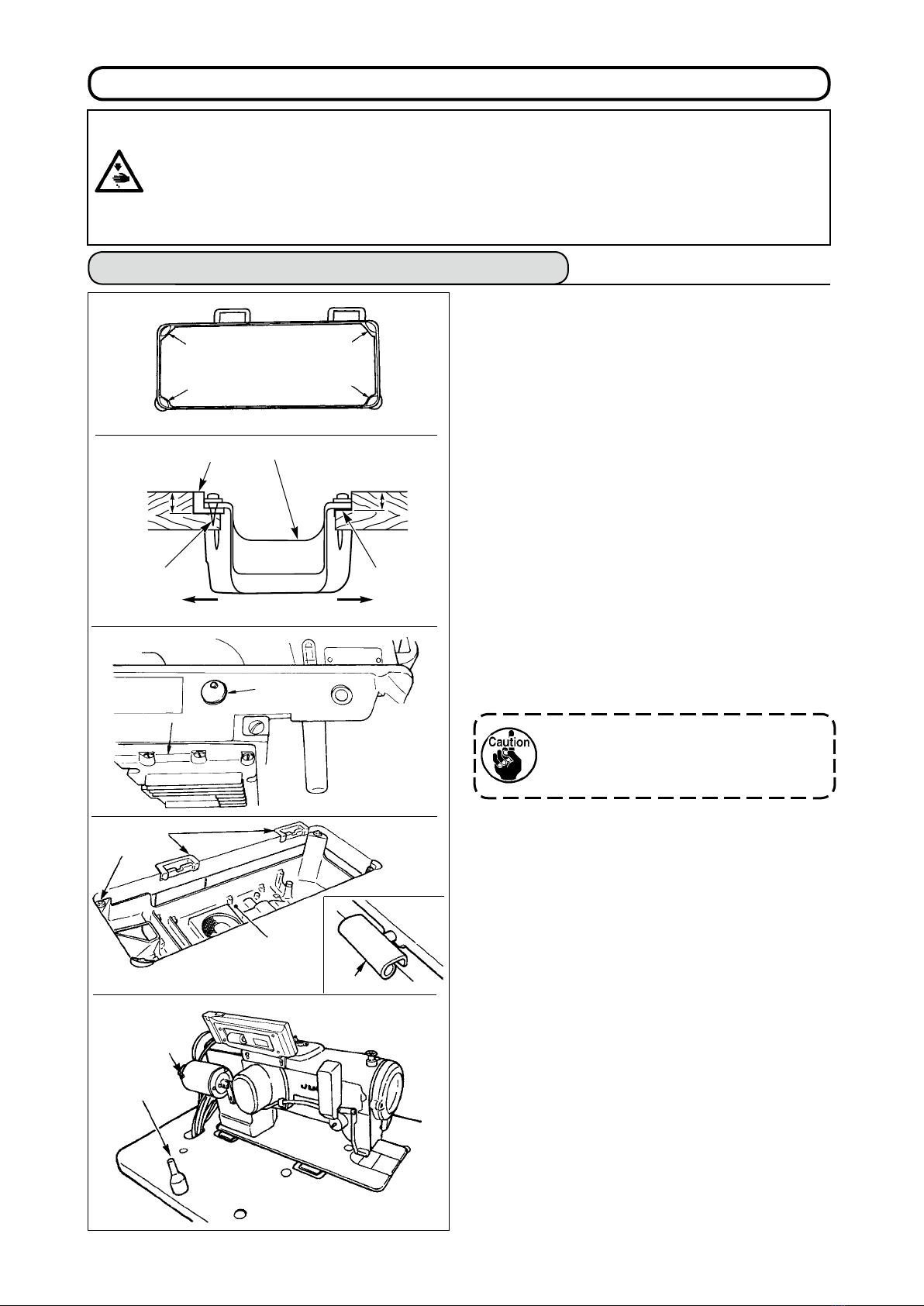

4. INSTALLATIoN............................................................................................................................. 4

4-1. Installation of the sewing machine head ..........................................................................................4

4-2. Removing the needle bar stopper .....................................................................................................5

4-3. Attaching the knee-lifter .....................................................................................................................5

4-4. Adjusting the height of the knee lifter...............................................................................................5

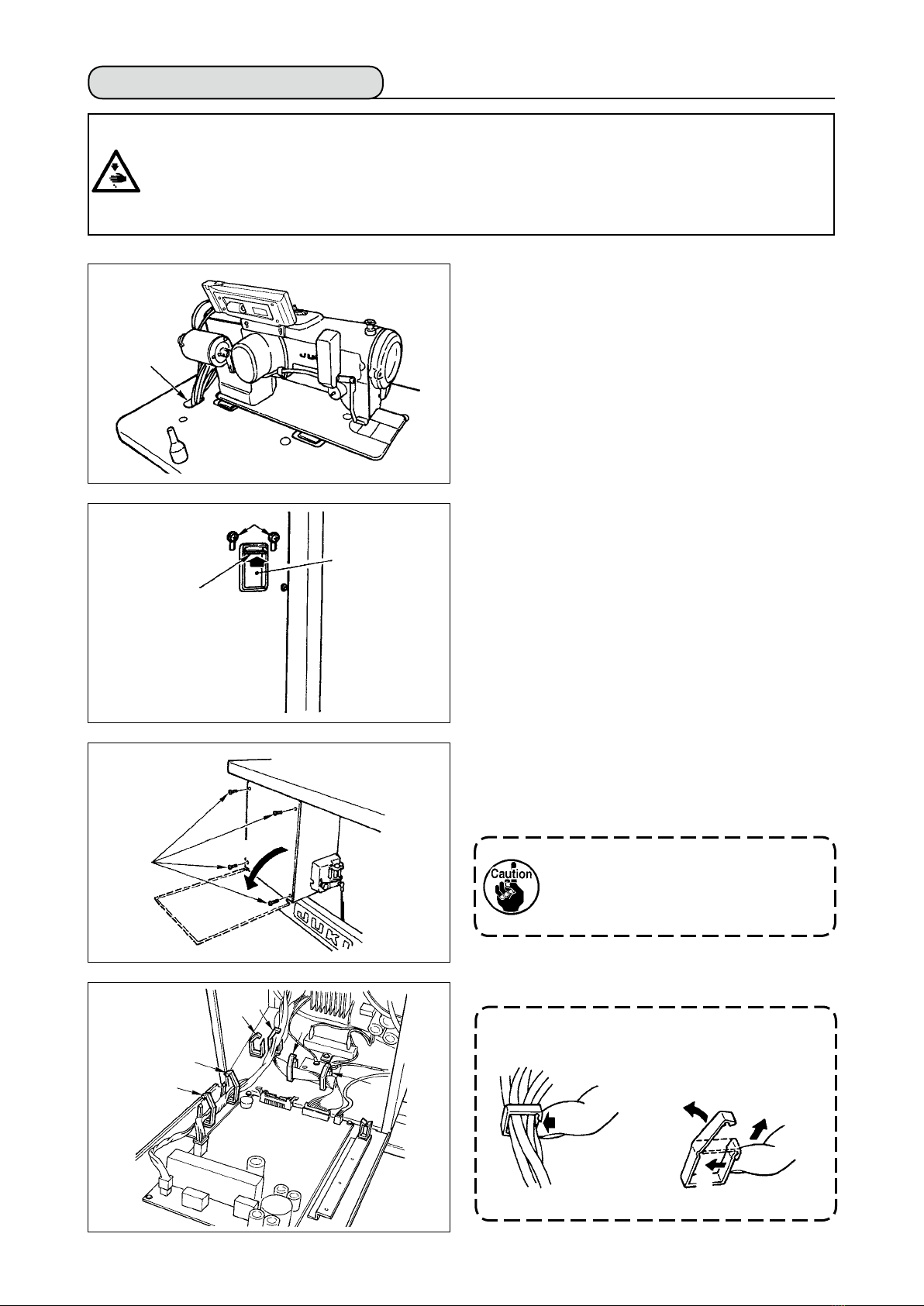

4-5. Installing the electrical box ................................................................................................................6

4-6. Connecting the power switch cord (Japan and general export area) ............................................6

4-7. Installing the operation panel (IT-100D) ............................................................................................ 6

4-8. Connecting the cords .........................................................................................................................7

(1) Preparation of wiring ........................................................................................................................................ 7

(2) Connecting the connectors............................................................................................................................... 8

4-9. Attaching the connecting rod .......................................................................................................... 11

4-10. Adjustment of the pedal ................................................................................................................. 11

4-11. Installing the thread stand.............................................................................................................. 12

4-12. Installing the bird’s nest prevention (CB) type sewing machine................................................12

4-13. Lubrication (LZ-2290A-SS • A-SU (-7) )..........................................................................................13

4-14. Test run ............................................................................................................................................14

(1) Turn ON the power......................................................................................................................................... 14

(2) How to operate the pedal ............................................................................................................................... 14

5. PrEPArATIoN BEForE SEWING ........................................................................................... 15

5-1. Inserting the needle .........................................................................................................................15

5-2. Removing the bobbin case ..............................................................................................................15

5-3. Winding the bobbin thread...............................................................................................................15

5-4. Placing the bobbin case and the bobbin ........................................................................................16

5-5. Threading the machine head ...........................................................................................................17

5-6. Adjusting the stitch length ...............................................................................................................17

5-7. Adjusting the condensation stitching .............................................................................................17

6. HoW To uSE THE oPErATIoN PANEL .................................................................................. 18

6-1. Names and functions of the respective sections...........................................................................18

6-2. Before setting the pattern ................................................................................................................20

(1) Limitation of the max. zigzag width ................................................................................................................ 20

(2) Setting the reference of stitch base line ......................................................................................................... 22

6-3. Basic screen .....................................................................................................................................23

6-4. List of the display pictographs of each screen..............................................................................24

6-5. Setting the sewing pattern ...............................................................................................................35

(1) Selecting the zigzag pattern .......................................................................................................................... 35

6-6. Setting of the sewing shape.............................................................................................................37

(1) 2-step zigzag, 3-step zigzag and 4-step zigzag stitch.................................................................................... 37

(2) Scallop stitching ............................................................................................................................................. 38

(3) Blind stitch sewing.......................................................................................................................................... 40

(4) Custom pattern stitching................................................................................................................................. 41

6-7. Reverse feed stitching......................................................................................................................42

(1) Standard condensation .................................................................................................................................. 43

(2) 2-point condensation ...................................................................................................................................... 44

(3) Condensation custom..................................................................................................................................... 46

(4) Comparison table of the reverse stitch of each shape ................................................................................... 47

6-8. Selection of the kind of stitching.....................................................................................................48

(1) Overlapped stitching....................................................................................................................................... 48

(2) Programmed stitching .................................................................................................................................... 48

6-9. Custom pattern..................................................................................................................................50

(1) Custom pattern setting ................................................................................................................................... 50

(2) New creation of the custom pattern ............................................................................................................... 51

(3) Custom pattern edit ........................................................................................................................................ 52

(4) Registration, copy and deletion of the custom pattern ................................................................................... 52

6-10. Condensation Custom....................................................................................................................54

(1) Condensation custom setting ......................................................................................................................... 54

(2) Condensation custom edit.............................................................................................................................. 55

6-11. Pattern stitching ..............................................................................................................................56

(1) Setting the pattern stitching............................................................................................................................ 56

(2) Registering the pattern stitching..................................................................................................................... 57

(3) Copy and deletion of the pattern stitching ...................................................................................................... 58