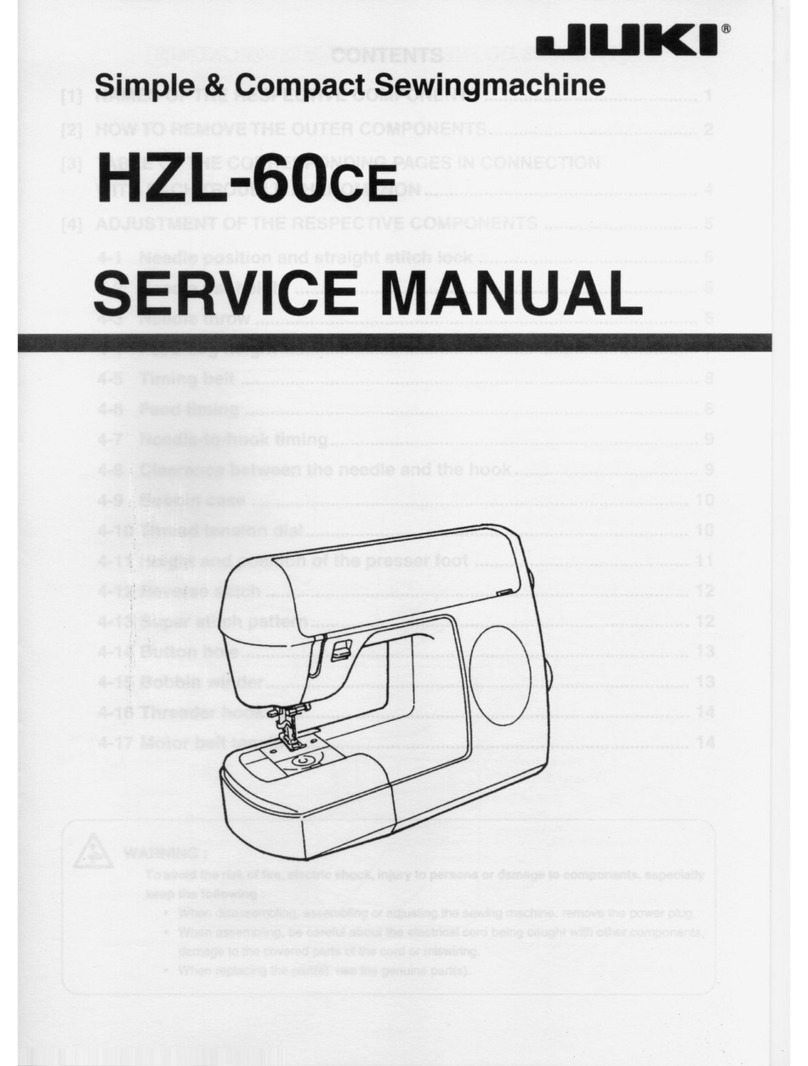

– 9 –

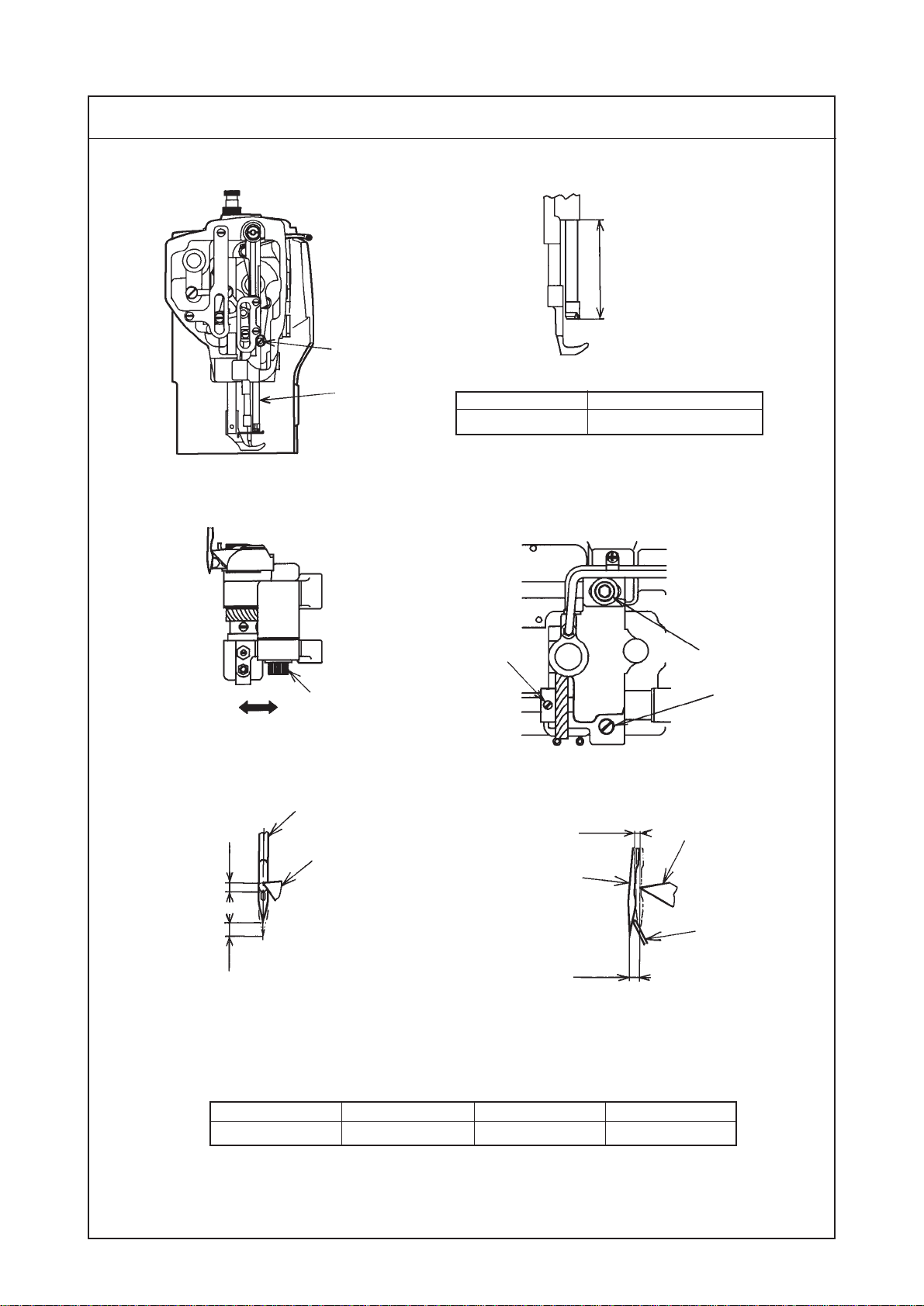

Adjustment Procedures Results of Improper Adjustment

™Stitch skipping or thread

breakage will result.

™Loose stitches will result.

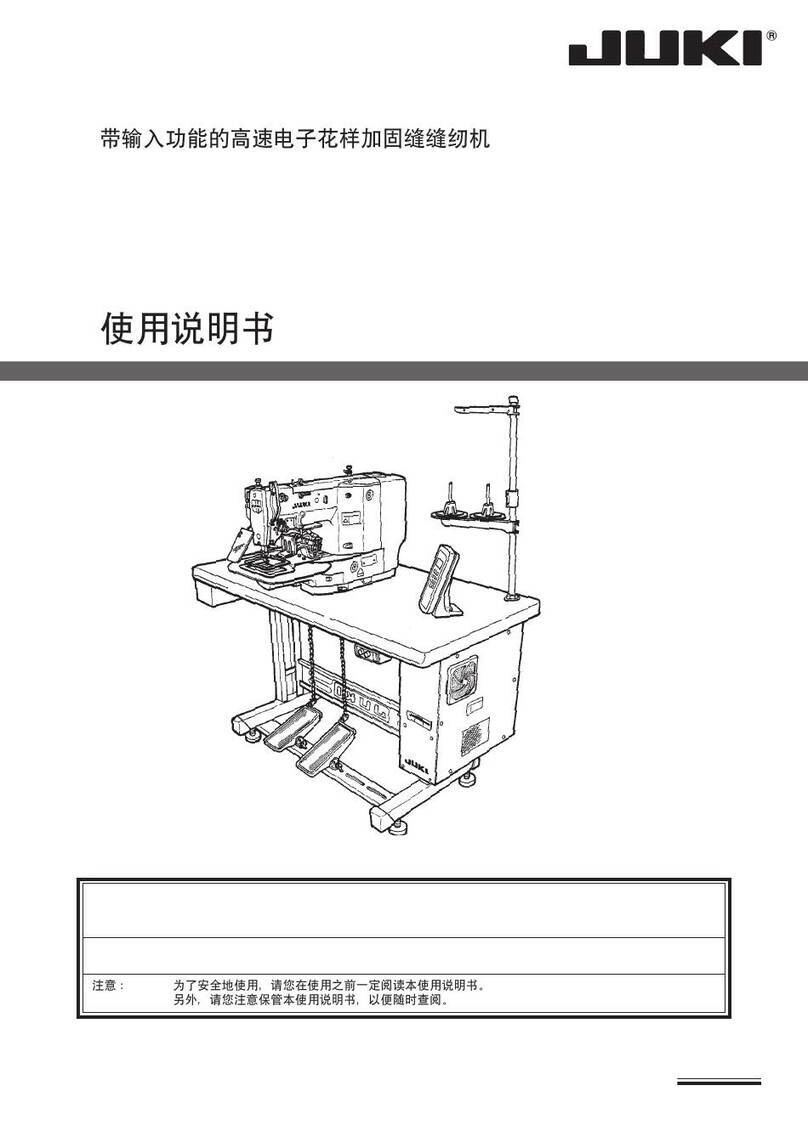

1) Standard of the lowest dead point of the needle bar

1. Set the stitch dial to “0”.

2. Turn the handwheel to bring needle bar 1to the lowest dead

point of its stroke.

3. Loosen the setscrew in the face plate to remove the face plate.

4. Loosen clamping screw 2in the needle bar holder. At this

time, loosen the screw to such an extent that needle bar 1

moves up and down by hand since needle bar 1drops if the

screw is fully loosened.

5. Adjust the distance from the lower end of needle bar frame to

the lower end of the needle bar to dimension A. Then tighten

clamping screw 2in the needle bar holder.

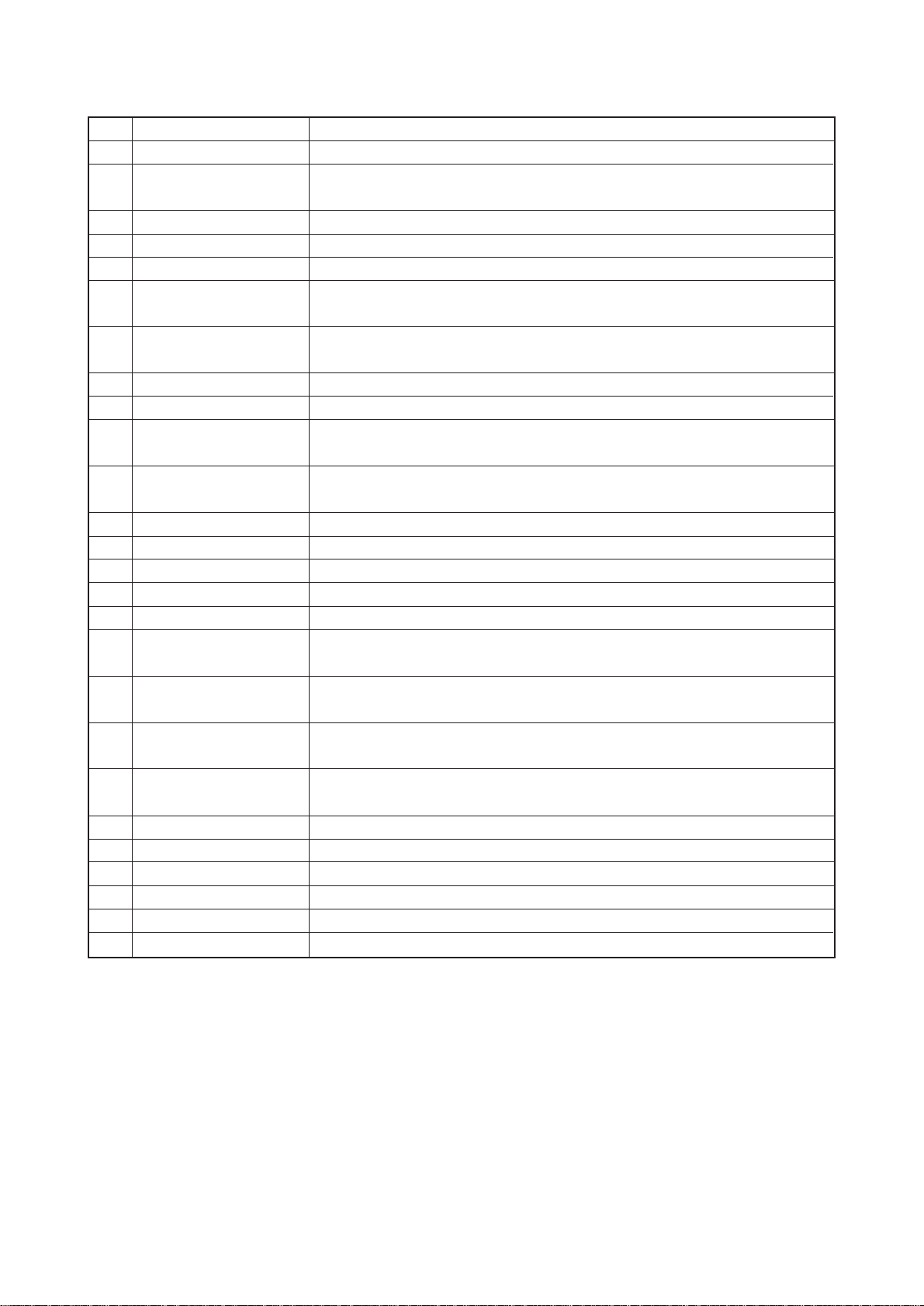

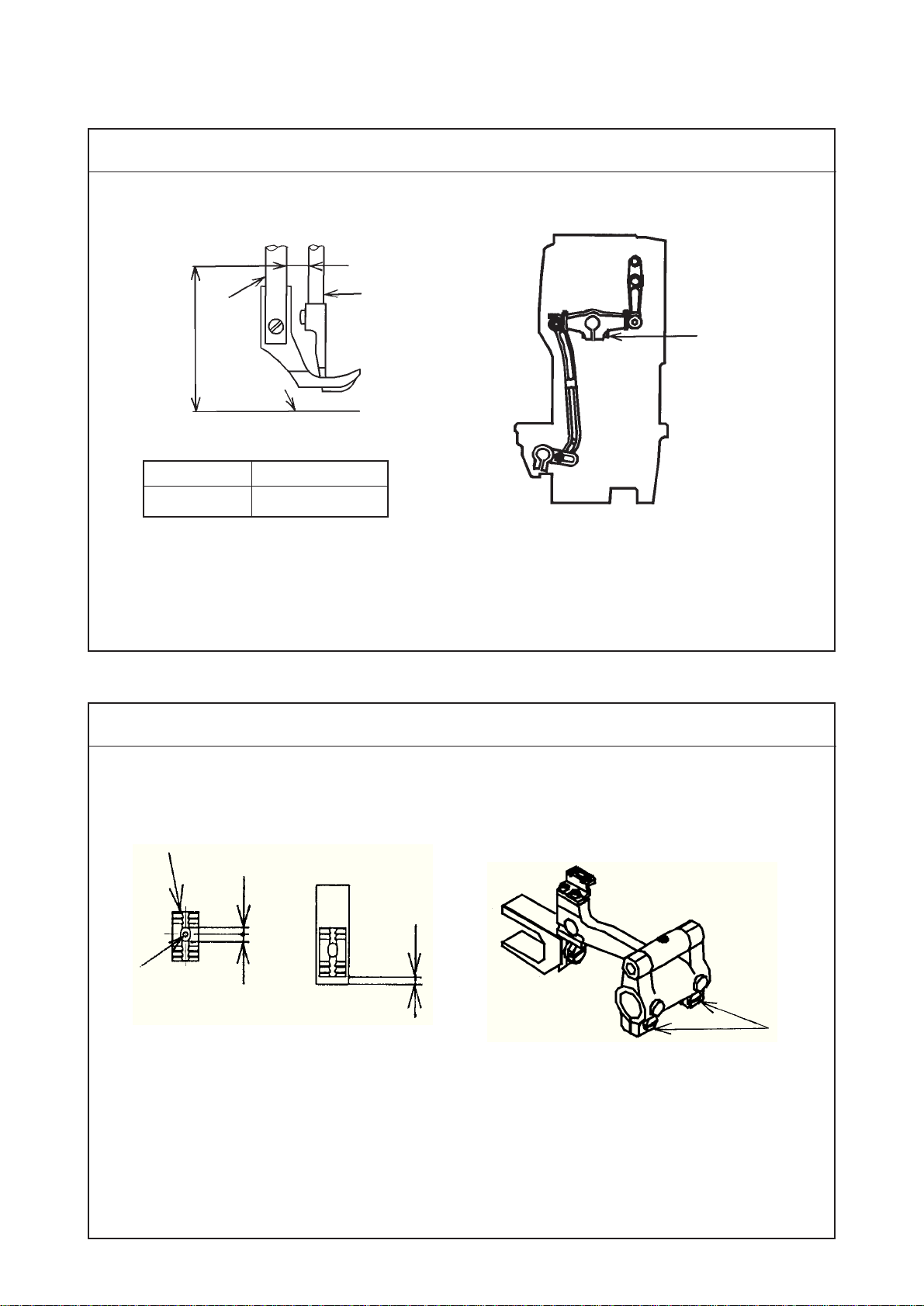

2) Needle-to-blade point of hook timing

1. Set the stitch dial to “0”.

2. Loosen two setcrews 3in the screw gear (large).

3. Turn the handwheel and when dimensions B and C are

approximately obtained, loosen setscrew A 4and setscrew B

8 in the hook shaft driving saddle. Then move the hook driving

shaft saddle to the right or left to adjust the cearance between

needle 5and blade point 6of the hook to dimension D. Then

securely tighten setscrew A 4and setscrew B 8.

4. Turn the handwheel and move the screw gear (large) to the

right or left so that needle 5aligns with blade point 6of the

hook when needle bar 1is raised from the lowest dead point

of its stroke to dimension B. Then tighten two setscrews 3.

5. Turn the handwheel and loosen clamping screw 2in the needle

bar holder to adjust so that the distance from the top end of the

eyelet of needle 5to blade point 6of the hook becomes

dimension C when needle bar 1is raised from the lowest dead

point of its stroke to dimension B. Then tighten again the

clamping screw.

6. Set the stitch dial to the maximum and check that needle 5

does not come in contact with blade point 6of the hook.

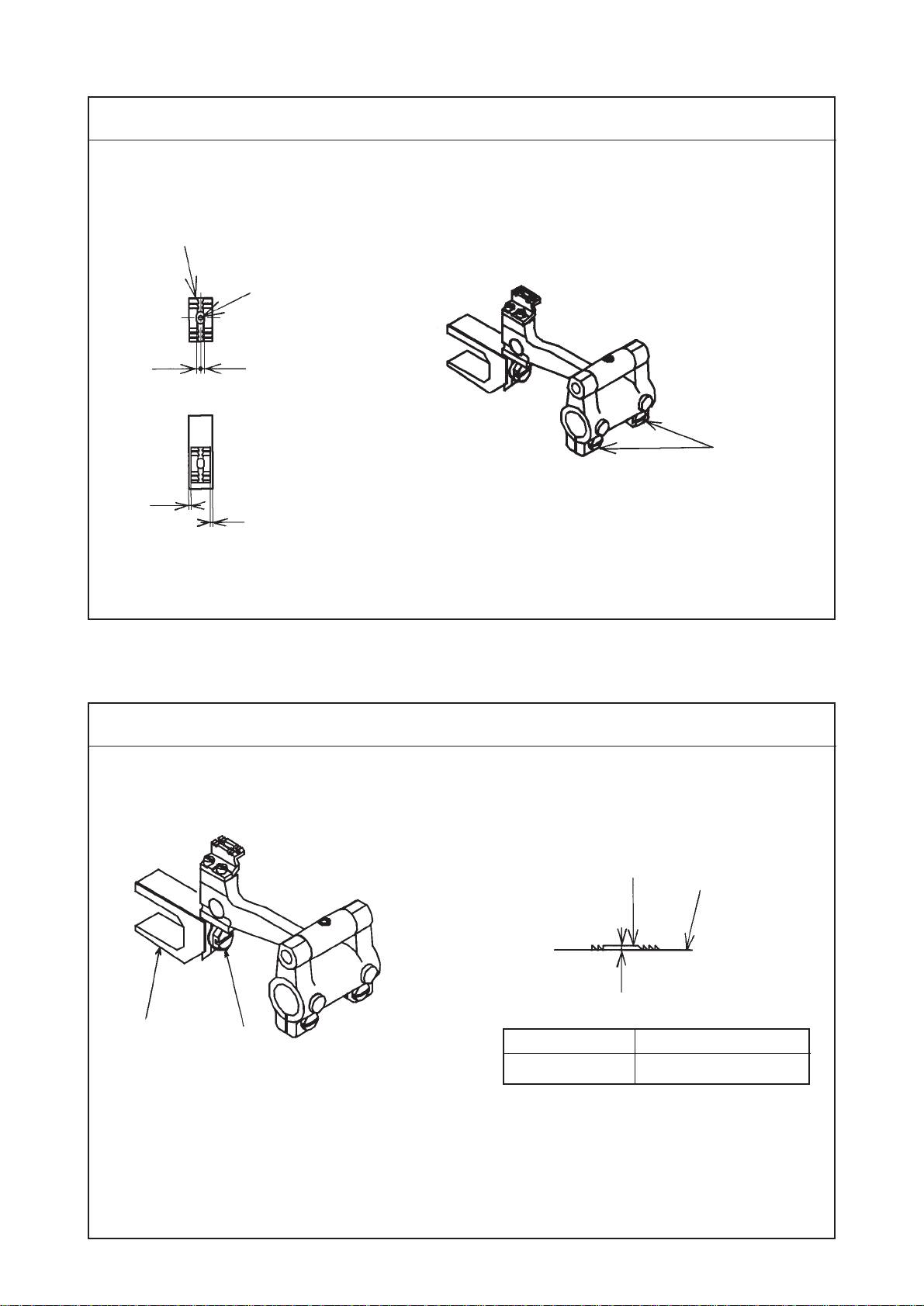

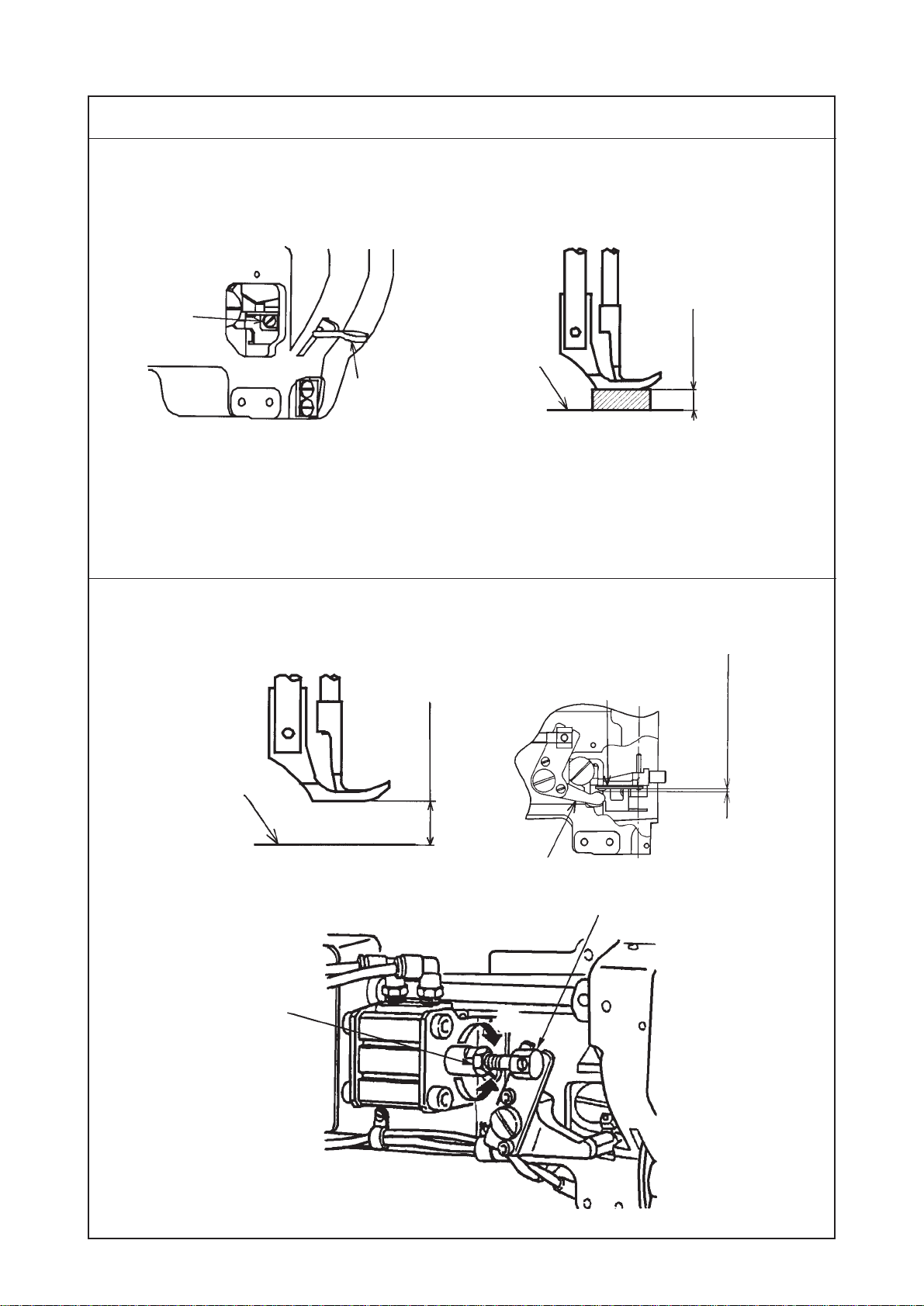

3) Adjusting the needle guard of the hook

1. Bend needle guard 7and adjust so that the needle guard 7

comes in contact 0.1 to 0.2 mm with the needle.

(Caution) 1. After tightening the hook shaft screw gear,

check that the hook shaft has no thrust play.

2. Check that the hook shaft screw gear has

backlash.