−5−

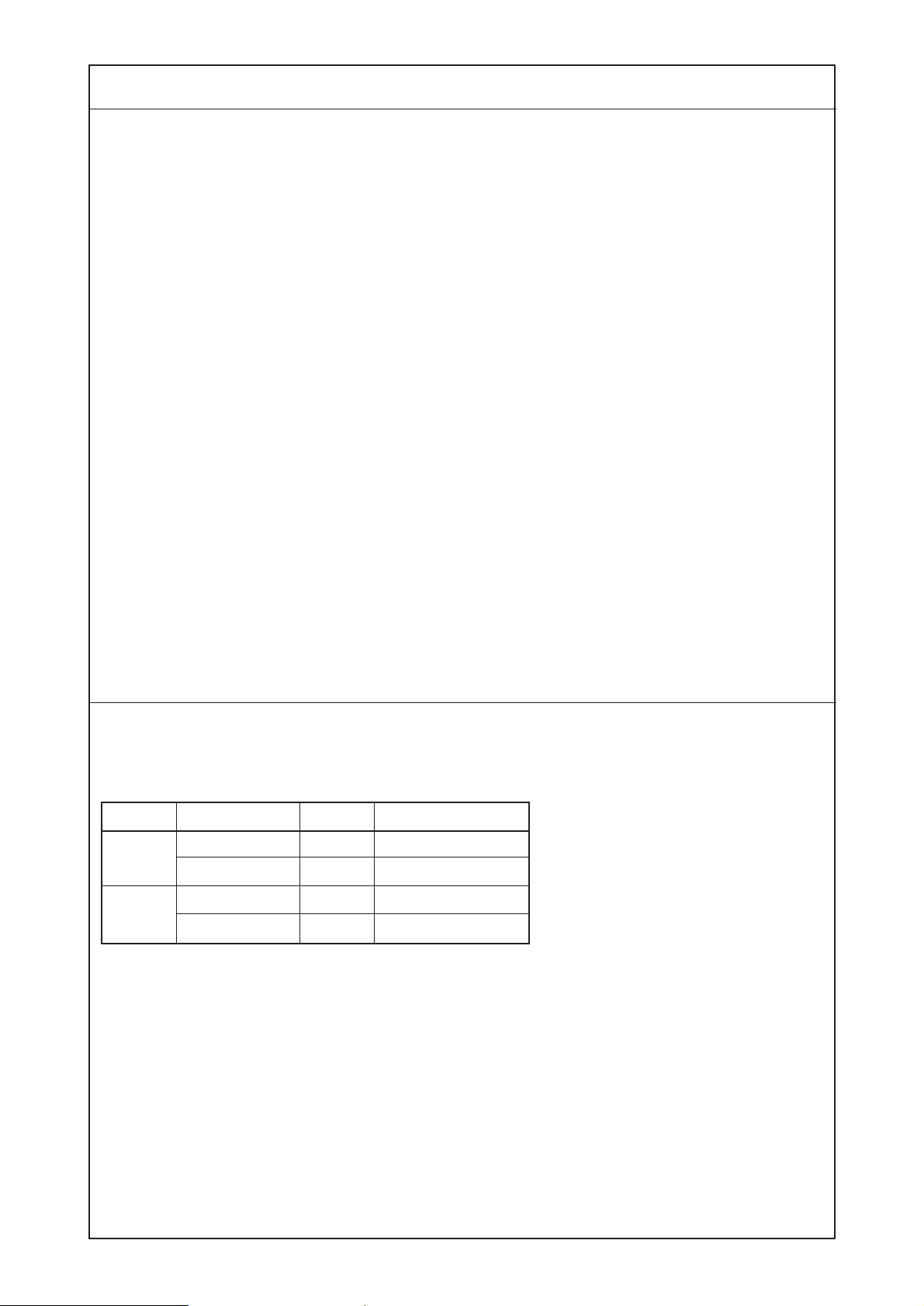

™For adjusting the timing of the travel of the yoke slide, align

the engraved marks of the loop positioning finger cam and

the triangle loop positioning finger cam with the engraved

mark of the cam and looper sleeve after the adjustment of

the looper so that the engraved marks are on a straight line.

Then temporarily tighten the screws.

1) Adjust the crosswise travel timing of the yoke slide in the

rotational direction of the triangle loop positioning finger cam.

When the timing is higher than 58 mm (48 mm), adjust the

timing in the rotational direction of the cam, and when it is

lower than 53 mm (43 mm), adjust the timing in the reverse

rotational direction of the cam.

The center of the cam is aligned with the center of the

positioning finger yoke slide in the longitudinal position of

the cam.

2) Adjust the lengthwise travel timing of the yoke slide in the

rotational direction of the loop positioning finger cam.

For the triangle movement of the yoke slide, it is good for

the yoke slide to go back like a slant line. When the yoke

slide goes back like a swollen line, adjust the cam in the

reverse rotational direction, and when it goes back like a

hollow line inside, adjust the cam in the rotational direction.

3) Adjust the longitudinal position of the yoke slide by moving

the loop positioning finger cam in the lengthwise direction.

™If the triangle loop positioning finger

cam begins to travel too late, thread

breakage, thread remaining, baloon

stitch, and insufficient tightness of

stitches will result.

On the contrary, if it begins to move

too early, the needle will come in

contact with the yoke slide.

™If the loop positioning finger cam

begins to go back too early, the

retreat of the yoke slide will become

like a swollen line and the looper

will hook the thread twice.

™On the other hand, if it begins to

retreat too late, its retreat will

become like a hollow line and the

needle will come in contact with the

yoke slide.

™If the longitudinal position of the

yoke slide is improper, the looper

will hook the thread twice or the

needle will come in contact with the

yoke slide.

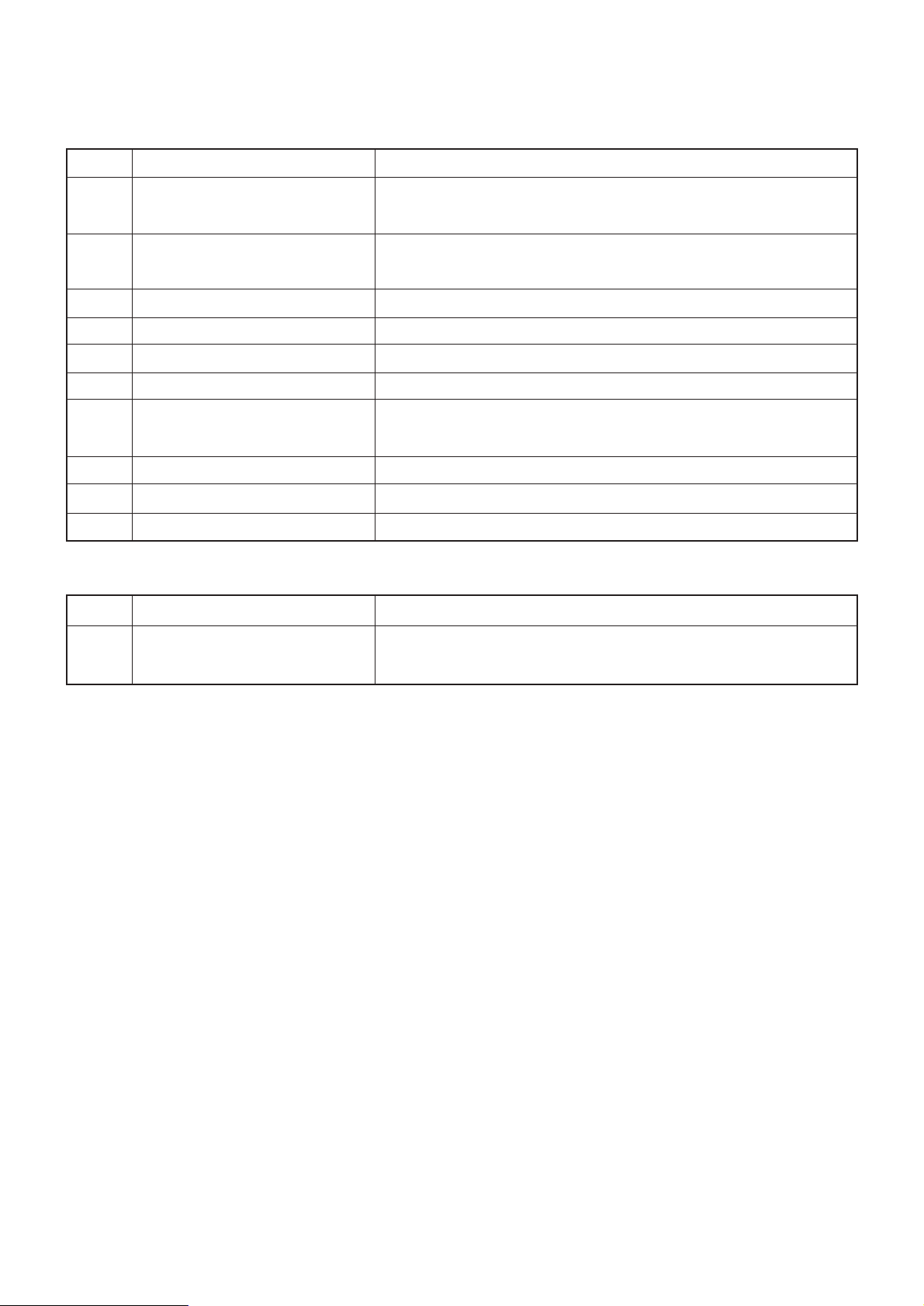

Adjustment Procedures Results of Improper Adjustment

Yoke slide retreats like

a swollen line.

Yoke slide retreats like

a hollow line.

Loop positioning

finger cam

Looper

Engraved mark

Triangle loop positioning

finger cam Cam and looper sleeve