i

CONTENTS

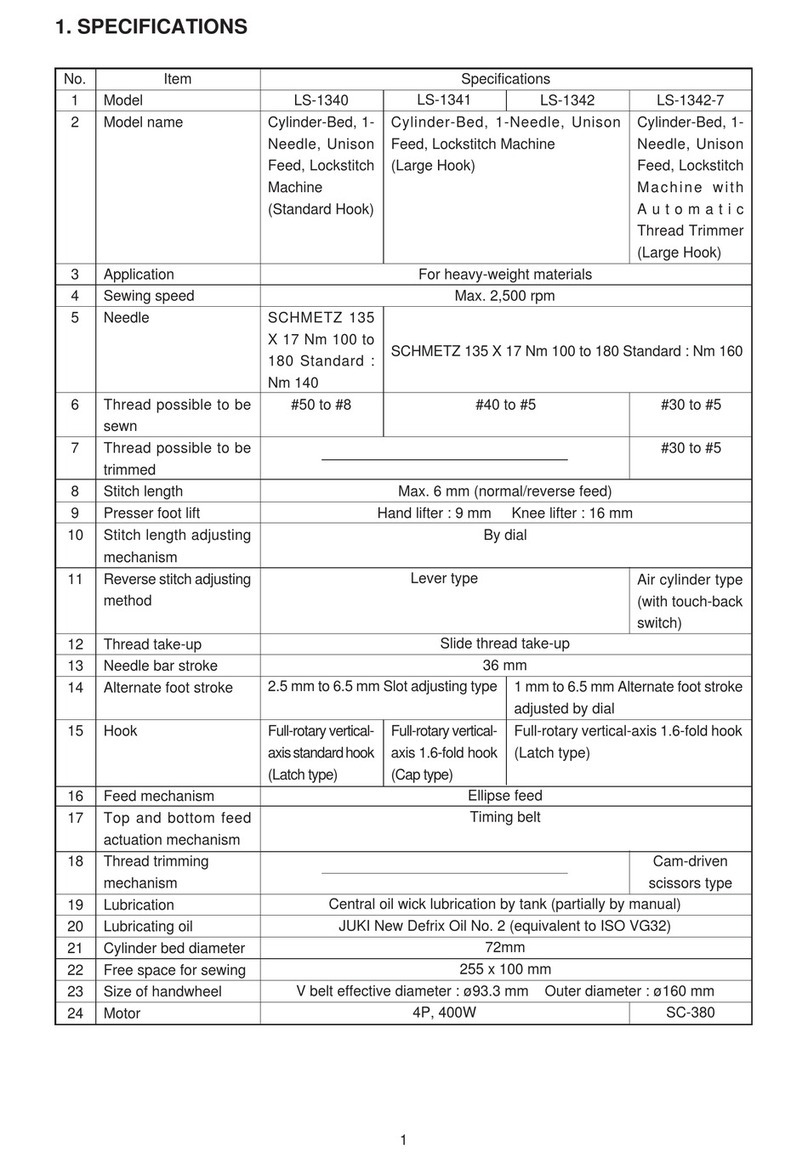

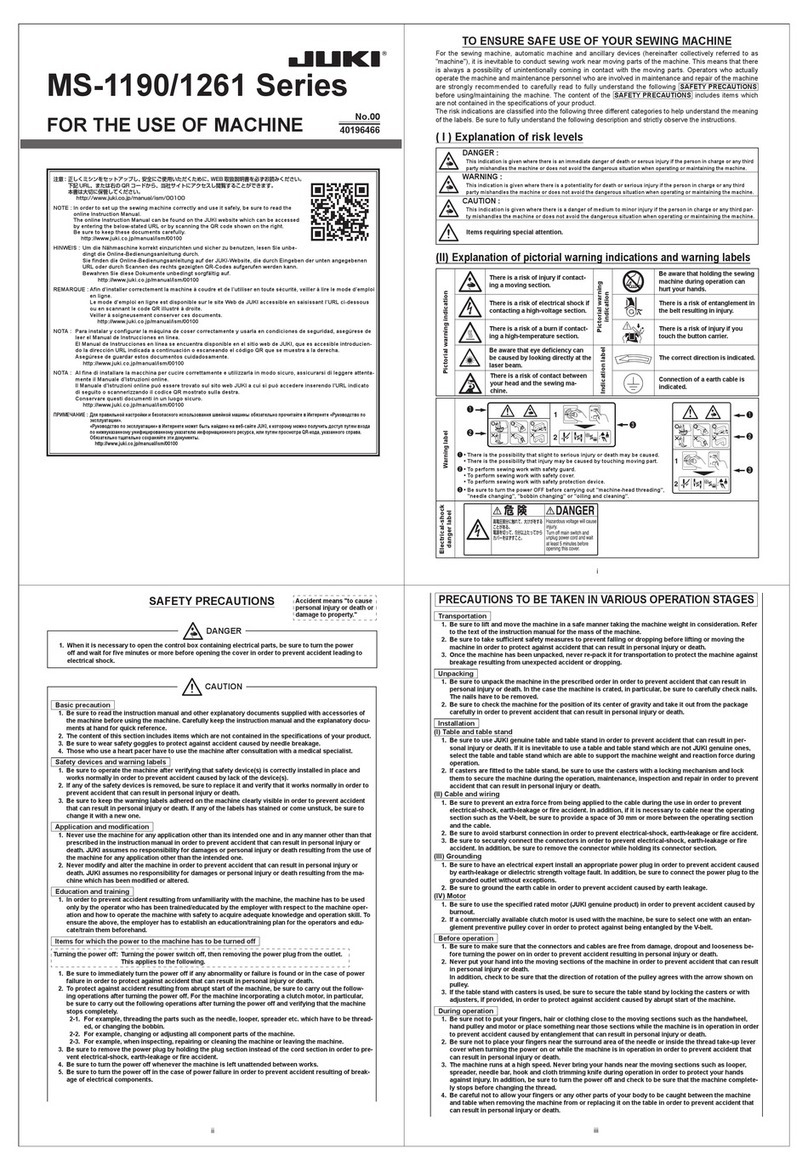

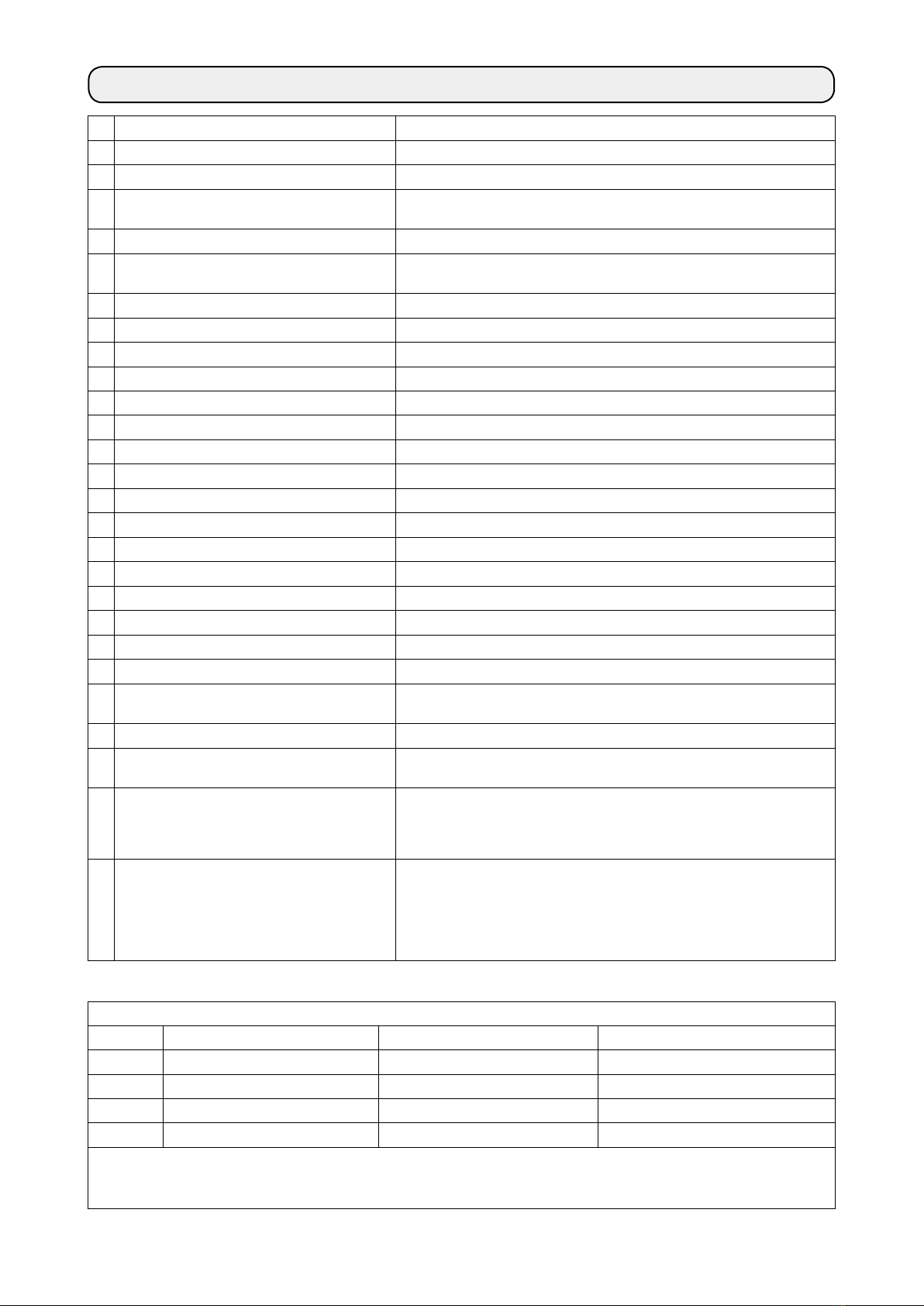

1. SPECIFICATIONS..................................................................................................................... 1

2. CONFIGURATION..................................................................................................................... 2

3. INSTALLATION ......................................................................................................................... 3

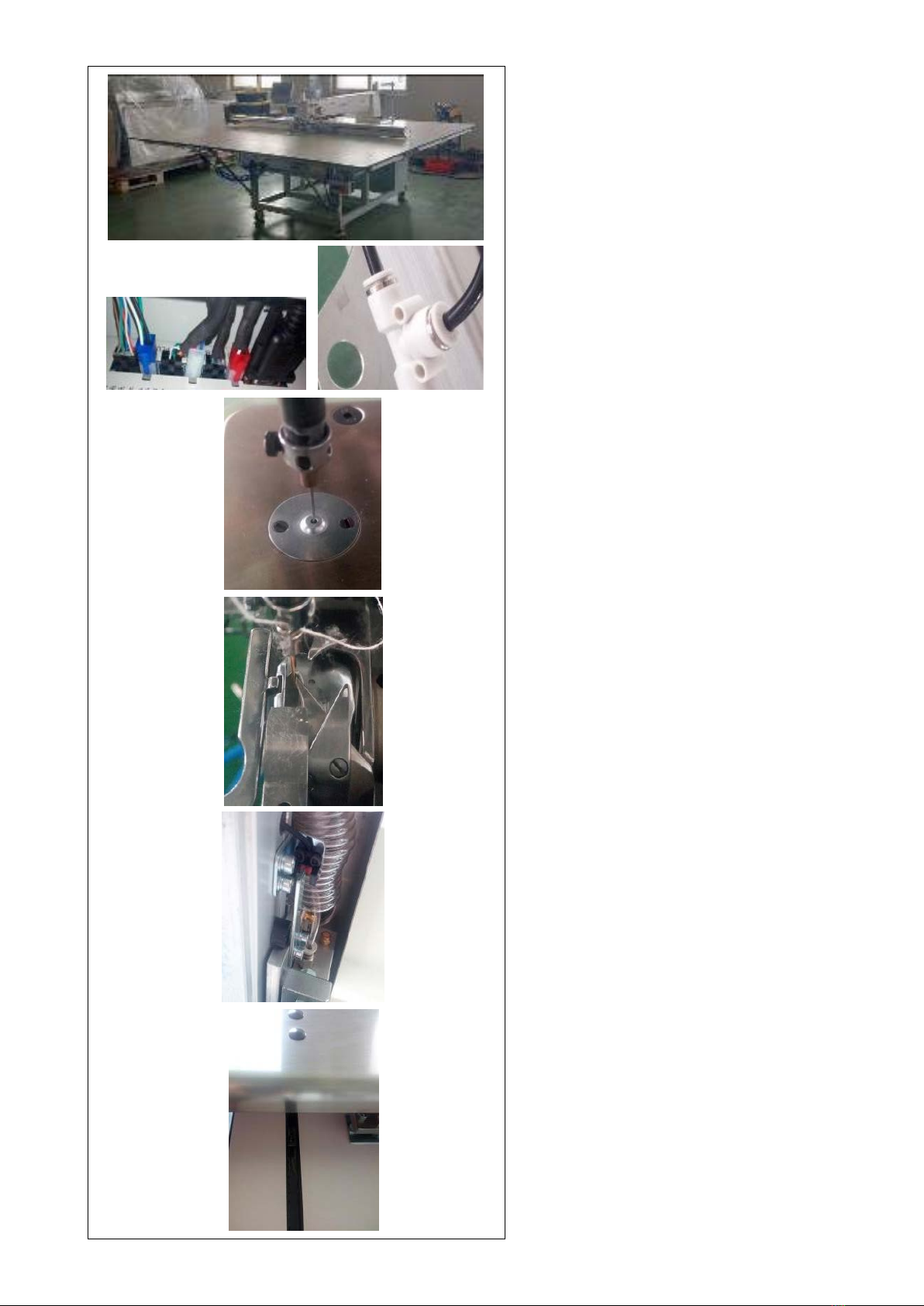

3-1. Setting up the sewing machine ....................................................................................................3

3-2. Installing the air hose ....................................................................................................................9

3-3. Cautions for the compressed air supply (source of supply air) facility .................................10

3-4. Installing the bobbin winder device ...........................................................................................11

3-5. Precautions for installation of the machine ..............................................................................11

4. PREPARATION OF THE SEWING MACHINE........................................................................ 12

4-1. Lubricating method and check of the oil quantity....................................................................12

4-2. Attaching the needle....................................................................................................................13

4-3. Threading the machine head ......................................................................................................14

4-4. Bobbin replacement procedure..................................................................................................15

4-5. Adjusting the thread tension ......................................................................................................16

4-6. Adjusting the thread take-up spring and the thread breakage detector plate .......................17

4-7. Adjusting the thread take-up stroke...........................................................................................17

4-8. Needle-to-hook relationship........................................................................................................18

4-9. How to wind a bobbin..................................................................................................................19

4-10. Adjusting the needle bar height..................................................................................................20

4-11. Adjusting the position of the thread trimmer ............................................................................21

4-12. How to attach / remove the cylinder lifting plate ......................................................................23

4-13. How to conrm the amount of oil (oil splashes) in the hook...................................................24

4-14. Adjusting the amount of oil in the hook.....................................................................................25

4-15. Adjusting the needle hole in the throat plate and the needle ..................................................26

4-16. Setting the mechanical origin .....................................................................................................27

4-17. Adjusting the disk presser pressure ..........................................................................................28

4-18. Adjusting the thread end position at the beginning of sewing................................................29

4-19. Adjusting the electronic intermediate presser stroke ..............................................................30

4-20. Adjusting the function for holding the thread by blowing air upward ....................................31

4-21. Making a template ........................................................................................................................32

4-22. Preparation for sewing ................................................................................................................34

4-23. Conguration of the operation panel .........................................................................................36

4-24. Maintenance mode.......................................................................................................................38

4-25. List of parameters ........................................................................................................................39

4-26. List of error codes........................................................................................................................45

5. MAINTENANCE OF SAWING MACHINE............................................................................... 50

5-1. Troubles and corrective measures (Sewing conditions)..........................................................55