CONTENTS

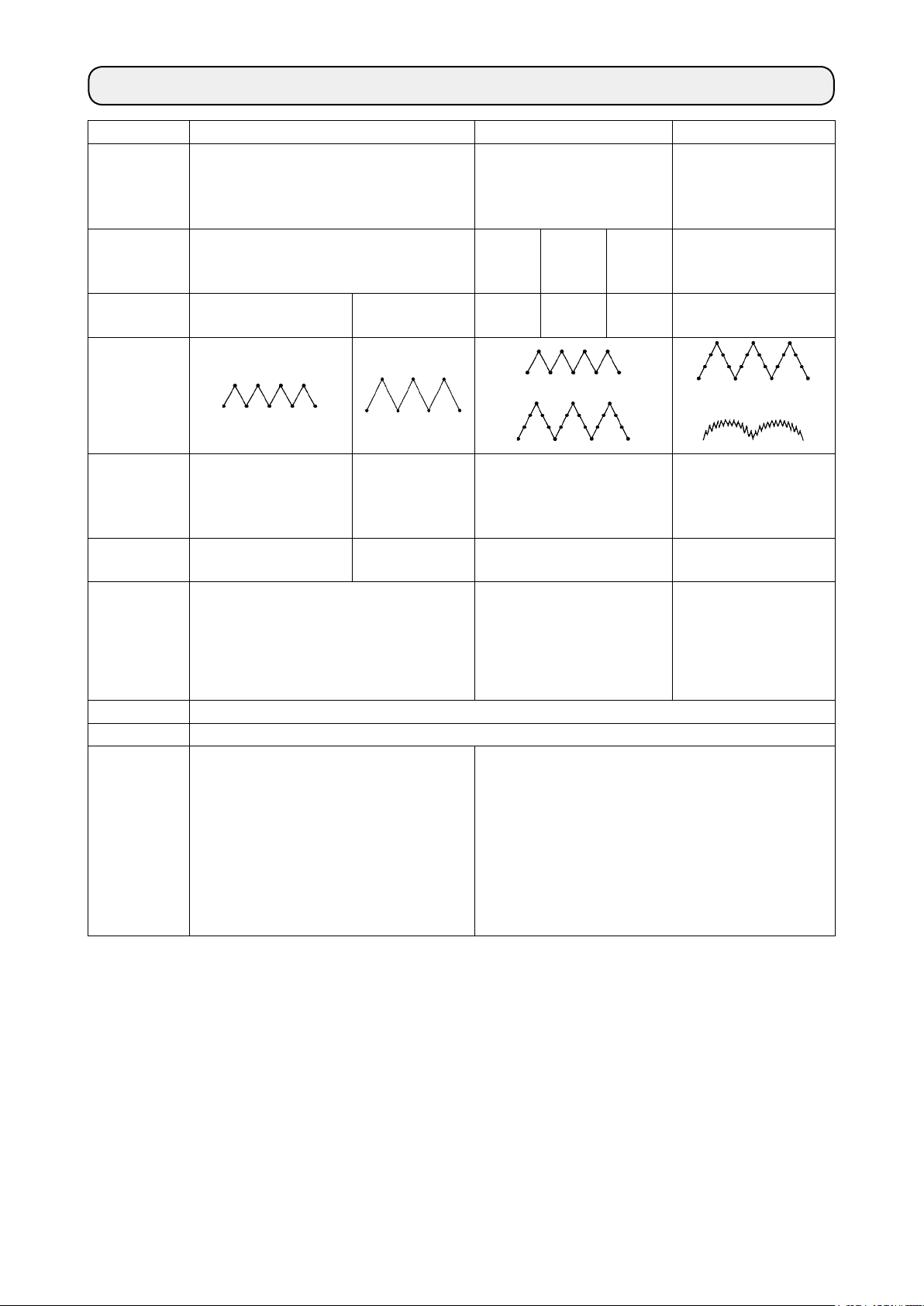

1. SPECIFICATIONS......................................................................................................... 1

2. INSTALLATION............................................................................................................. 4

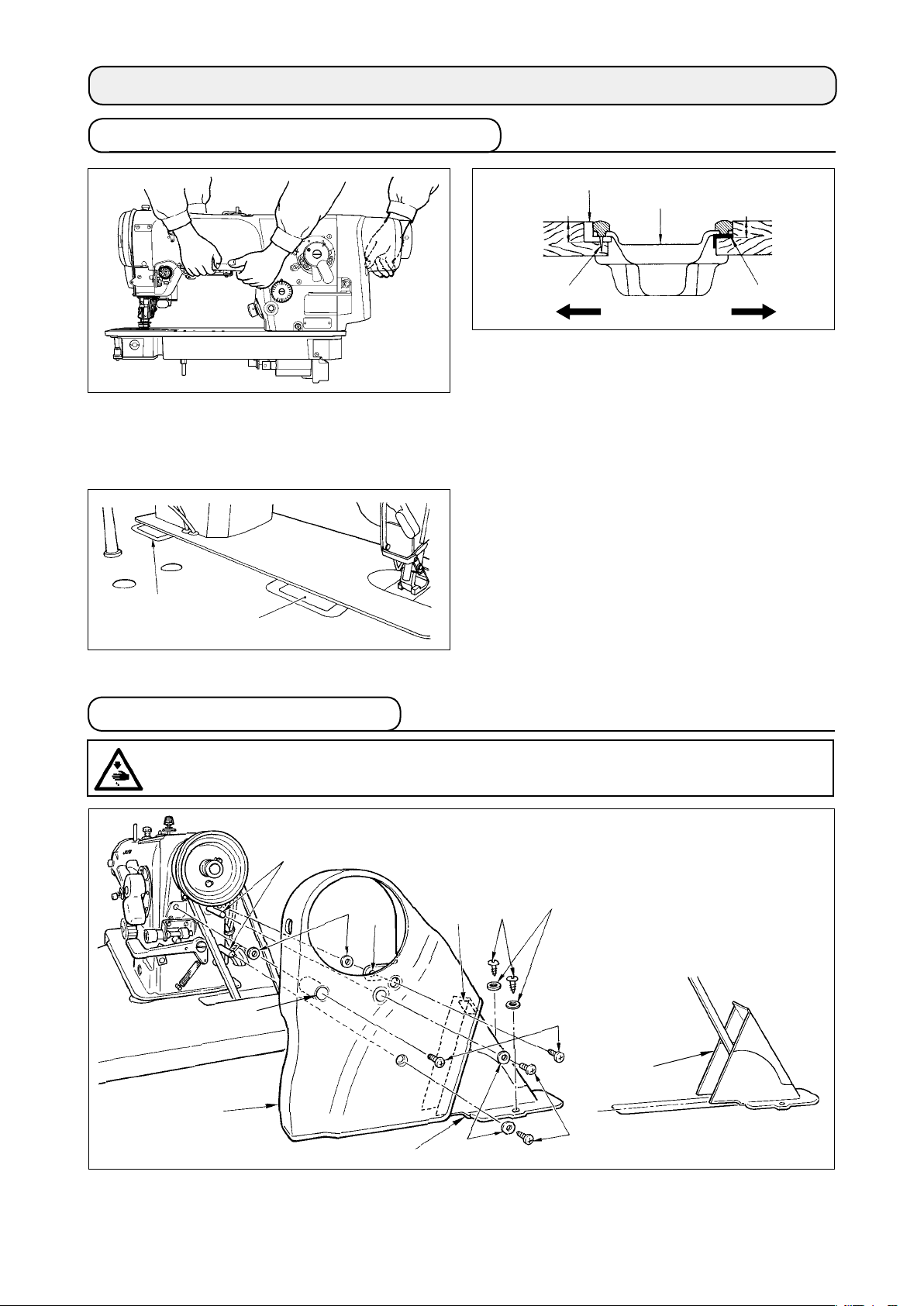

2-1. Installation of the sewing machine...............................................................................................4

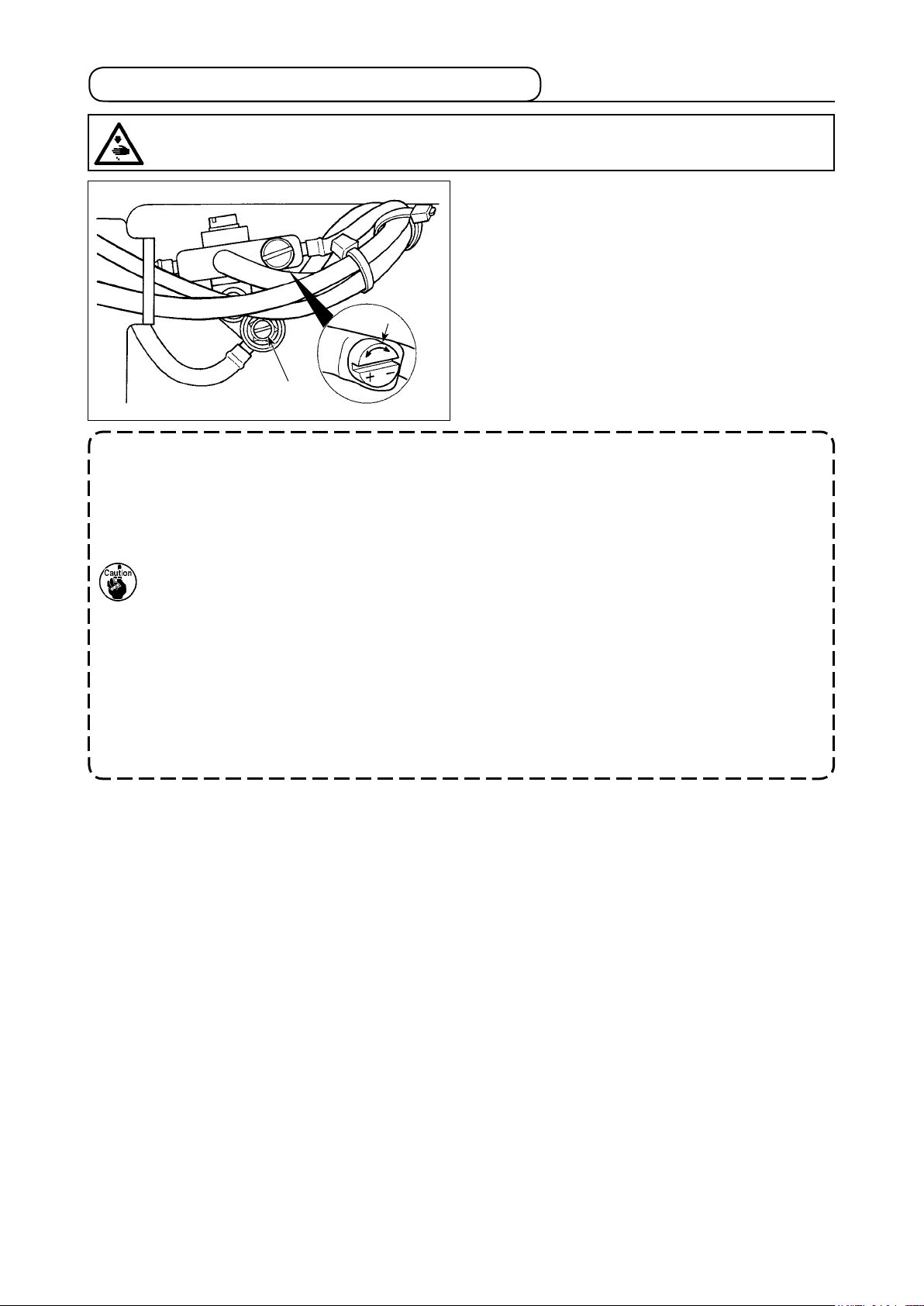

2-2. Attaching the belt cover ................................................................................................................4

2-3. Inserting the needle .......................................................................................................................5

2-4. Installing the control panel ........................................................................................................... 6

3. PREPARATION OF THE SEWING MACHINE ............................................................. 6

3-1. Lubrication......................................................................................................................................6

3-2. Adjusting the amount of oil in the hook ......................................................................................7

3-3. Adjusting the amount of oil (oil splashes)................................................................................... 8

3-4. Winding the bobbin thread............................................................................................................9

3-5. Inserting the bobbin case and the bobbin................................................................................. 10

3-6. Threading the machine head ...................................................................................................... 11

3-7. Adjusting the pedal...................................................................................................................... 11

4. ADJUSTING THE SEWING MACHINE ...................................................................... 12

4-1. Adjusting the thread tension ......................................................................................................12

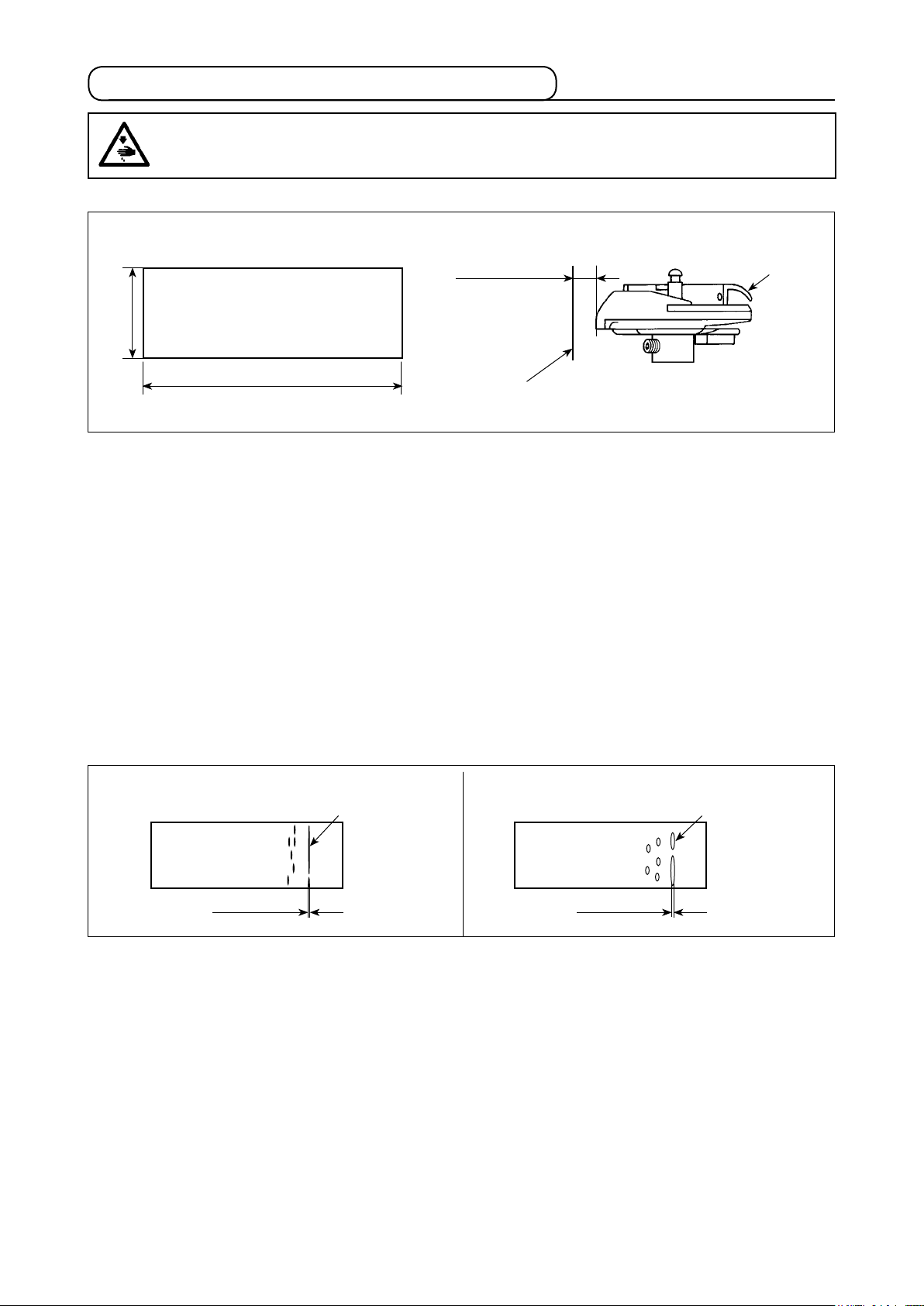

4-2. Adjusting the zigzag width..........................................................................................................13

4-3. Adjusting the pressure of the presser foot ............................................................................... 14

4-4. Adjusting the height of the presser bar .....................................................................................14

4-5. Adjusting the micro-lifting mechanism of the presser foot ..................................................... 14

4-6. Adjusting the stitch length..........................................................................................................15

4-7. Adjusting the denser stitching ...................................................................................................15

4-8. Height and inclination of the feed dog....................................................................................... 16

4-9. Attaching/removing the hook .....................................................................................................16

4-10. Adjusting height of the needle bar ............................................................................................. 17

4-11. Adjusting the needle-to-hook timing and the needle guard..................................................... 17

4-12. Adjusting the stop position of the needle..................................................................................18

4-13. Adjusting the thread trimmer...................................................................................................... 19

4-14. Needle thread feeding device ..................................................................................................... 20

4-15. Position of the wiper.................................................................................................................... 20

5. OPERATION OF THE SEWING MACHINE................................................................ 21

5-1. How to operate the pedal (In the case of the direct-drive type sewing machine).................. 21

5-2. One-touch type reverse feed switch .......................................................................................... 21

5-3. Changing over the needle-throwing method............................................................................. 22

5-4. LED light ....................................................................................................................................... 22

6. OPTIONAL .................................................................................................................. 23

6-1. Pedal-operated reverse feed device (RF-1) ............................................................................... 23

6-2. Joining foot for the lockstitch presser foot............................................................................... 23

6-3. Auxiliary thread take-up kit .........................................................................................................23

7. MOTOR PULLEY AND BELT ..................................................................................... 24

8. TROUBLES AND CORRECTIVE MEASURES .......................................................... 25