i

CONTENTS

!. SPECIFICATIONS ..................................................................................... 1

@. SET-UP...................................................................................................... 3

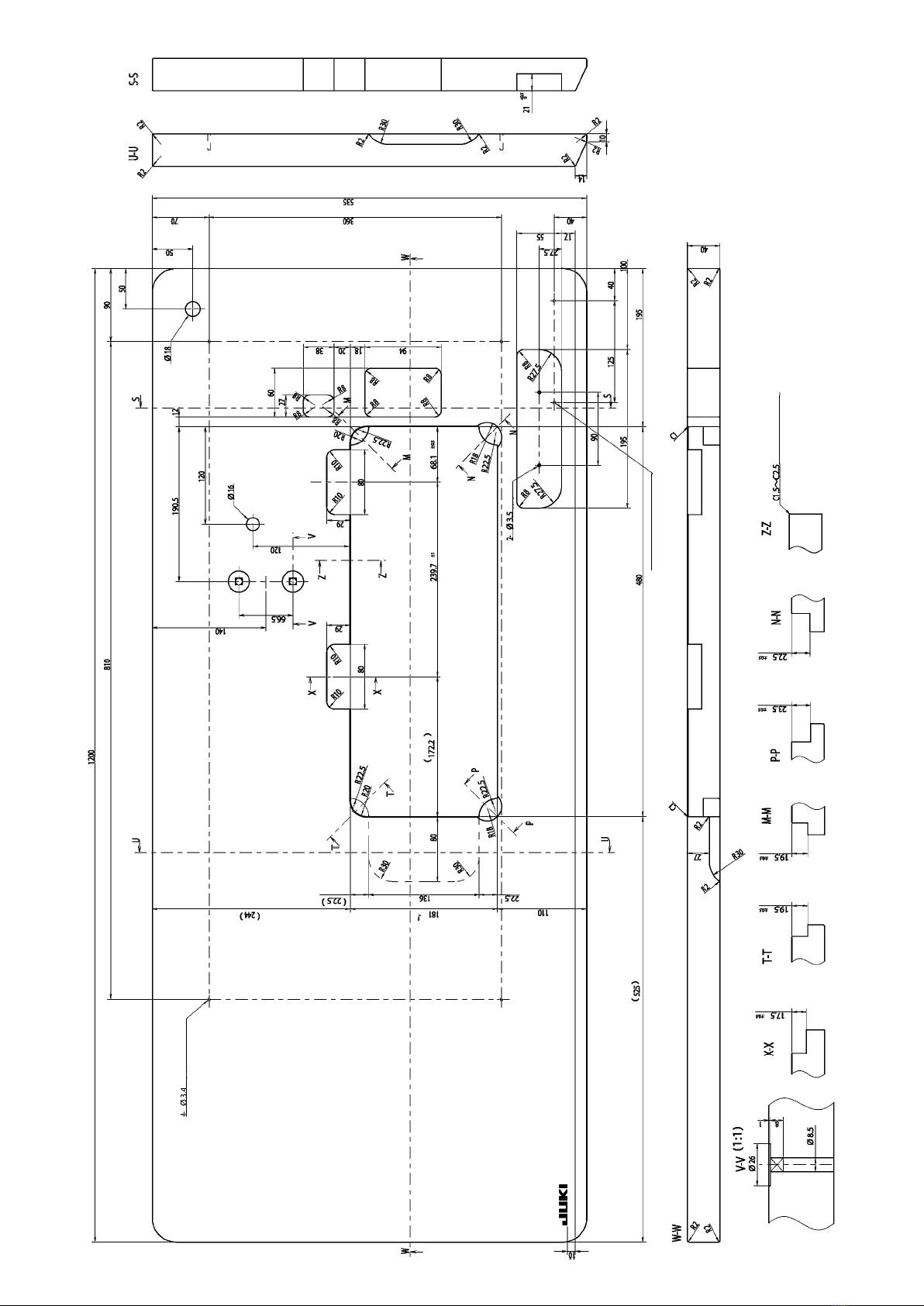

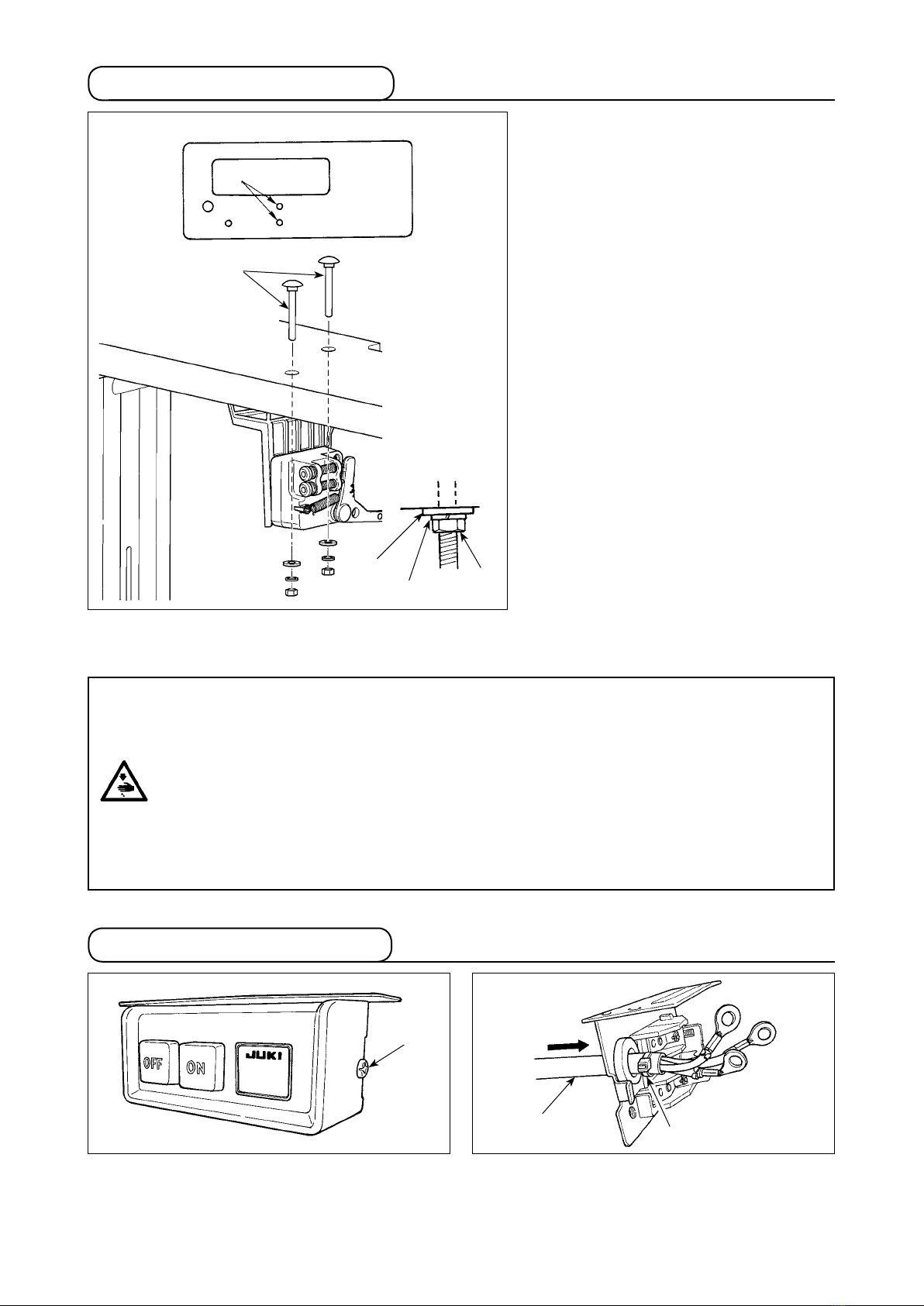

1. Installation.................................................................................................................. 3

2. Installing the pedal sensor ....................................................................................... 4

3. Installing the power switch....................................................................................... 4

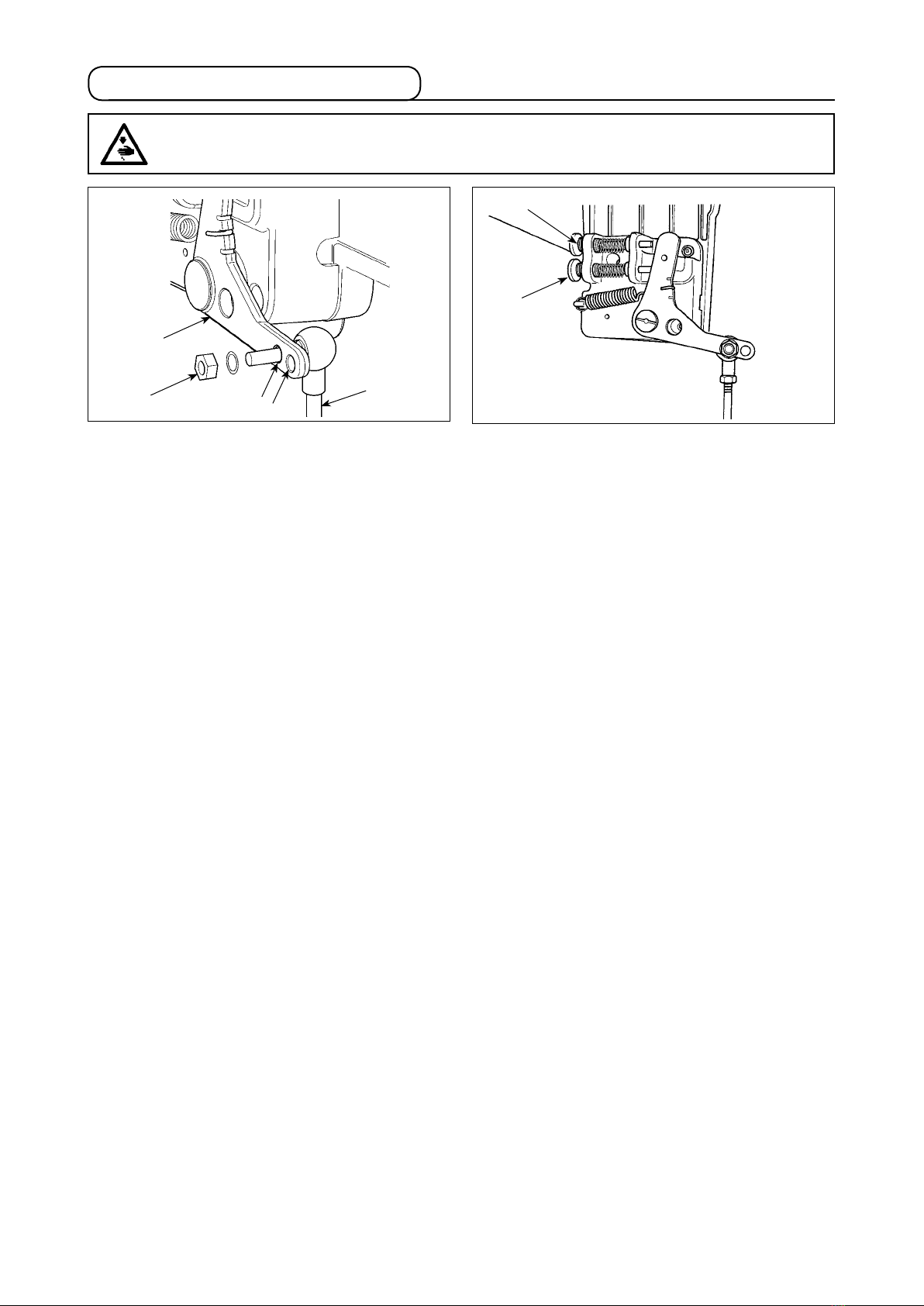

4. Attaching the connecting rod ................................................................................... 6

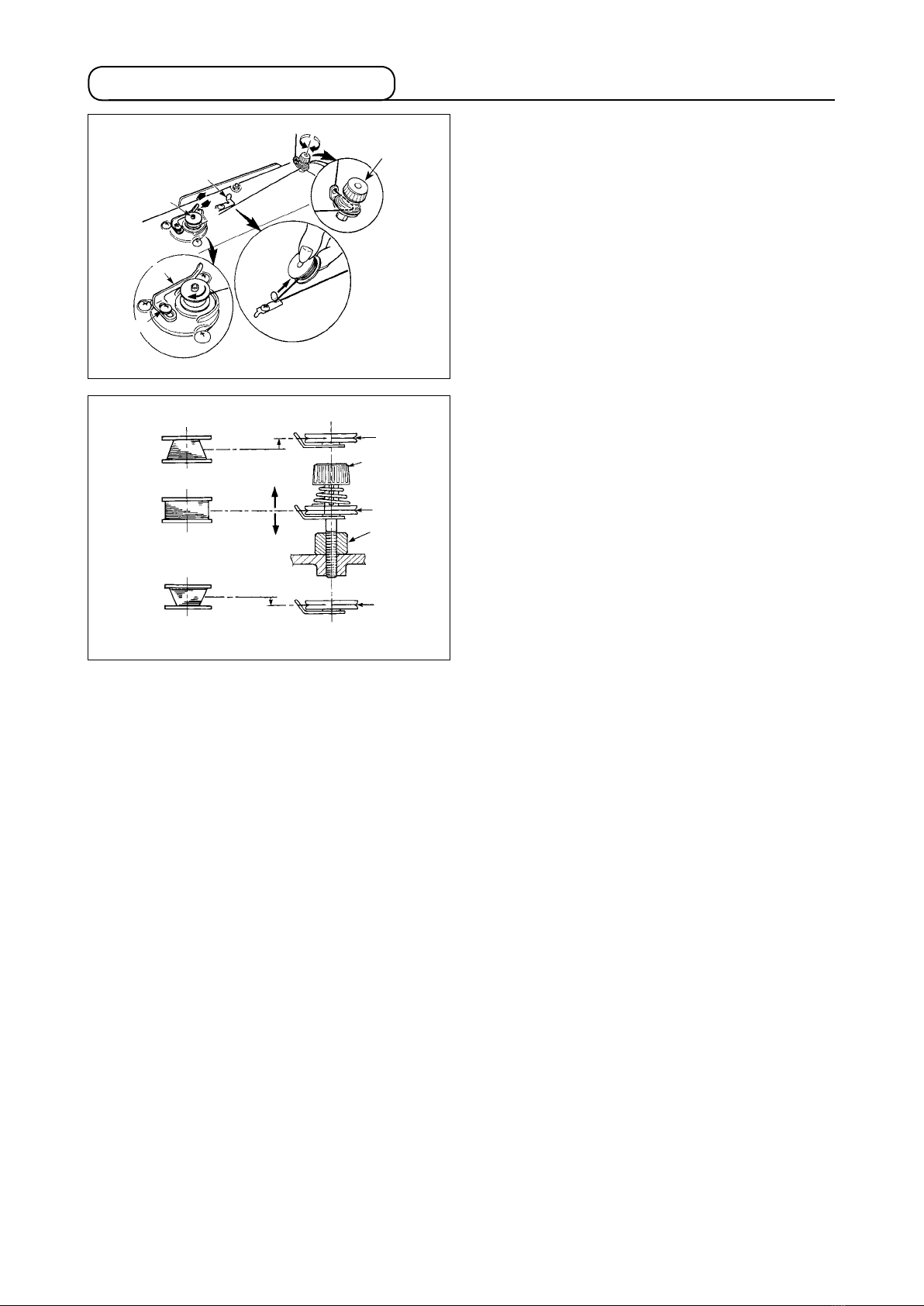

5. Winding the bobbin thread ....................................................................................... 7

6. Adjusting the height of the knee lifter ..................................................................... 8

7. Installing the thread stand ........................................................................................ 8

8. Lubrication ................................................................................................................. 9

9. Adjusting the amount of oil (oil splashes) .............................................................. 9

10. Attaching the needle...............................................................................................11

11. Setting the bobbin into the bobbin case ............................................................. 12

12. Adjusting the stitch length.................................................................................... 12

13. Presser foot pressure............................................................................................ 12

14. Hand lifter ............................................................................................................... 12

15. Adjusting the height of the presser bar............................................................... 13

16. Threading the machine head ................................................................................ 13

17. Thread tension ....................................................................................................... 14

18. Thread take-up spring ........................................................................................... 14

19. Adjusting the thread take-up stroke .................................................................... 14

20. Needle-to-hook relationship ................................................................................. 15

21. Height of the feed dog........................................................................................... 15

22. Tilt of the feed dog................................................................................................. 16

23. Adjusting the feed timing...................................................................................... 16

24. Cunter knife............................................................................................................ 17

25. Pedal pressure and pedal stroke ......................................................................... 17

26. Adjustment of the pedal ........................................................................................ 18

#. FOR THE OPERATOR ............................................................................ 19

1. Operating procedure of the sewing machine........................................................ 19

2. Built-in panel of the machine head ........................................................................ 21

3. Operating procedure of the sewing pattern .......................................................... 22

4. One-touch setting .................................................................................................... 24

5. Production support function .................................................................................. 25

6. Setting of functions ................................................................................................. 28

7. Function setting list................................................................................................. 29

8. Detailed explanation of selection of functions ..................................................... 33

9. Automatic compensation of neutral point of the pedal sensor........................... 43

10. Selection of the pedal specications................................................................... 43