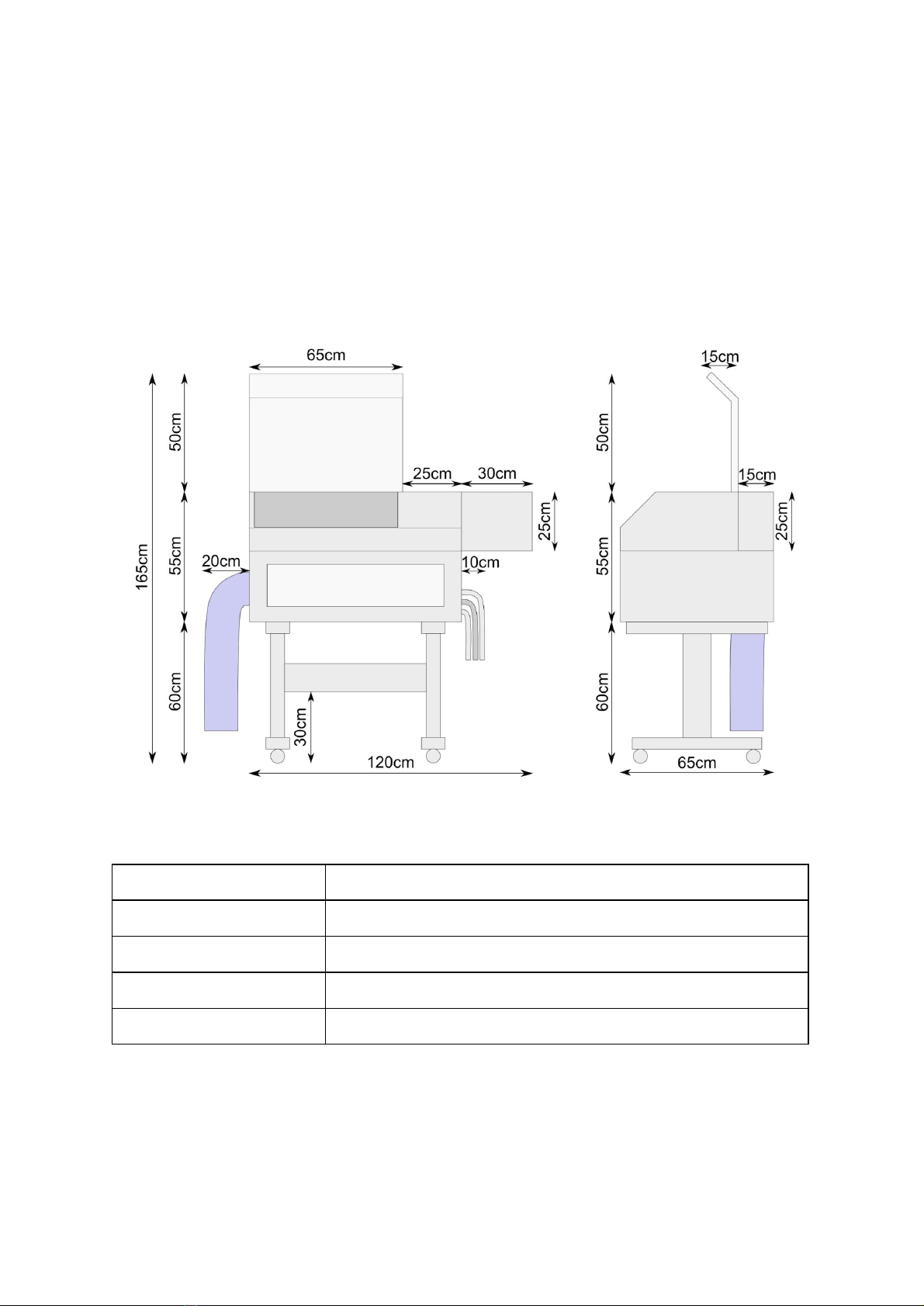

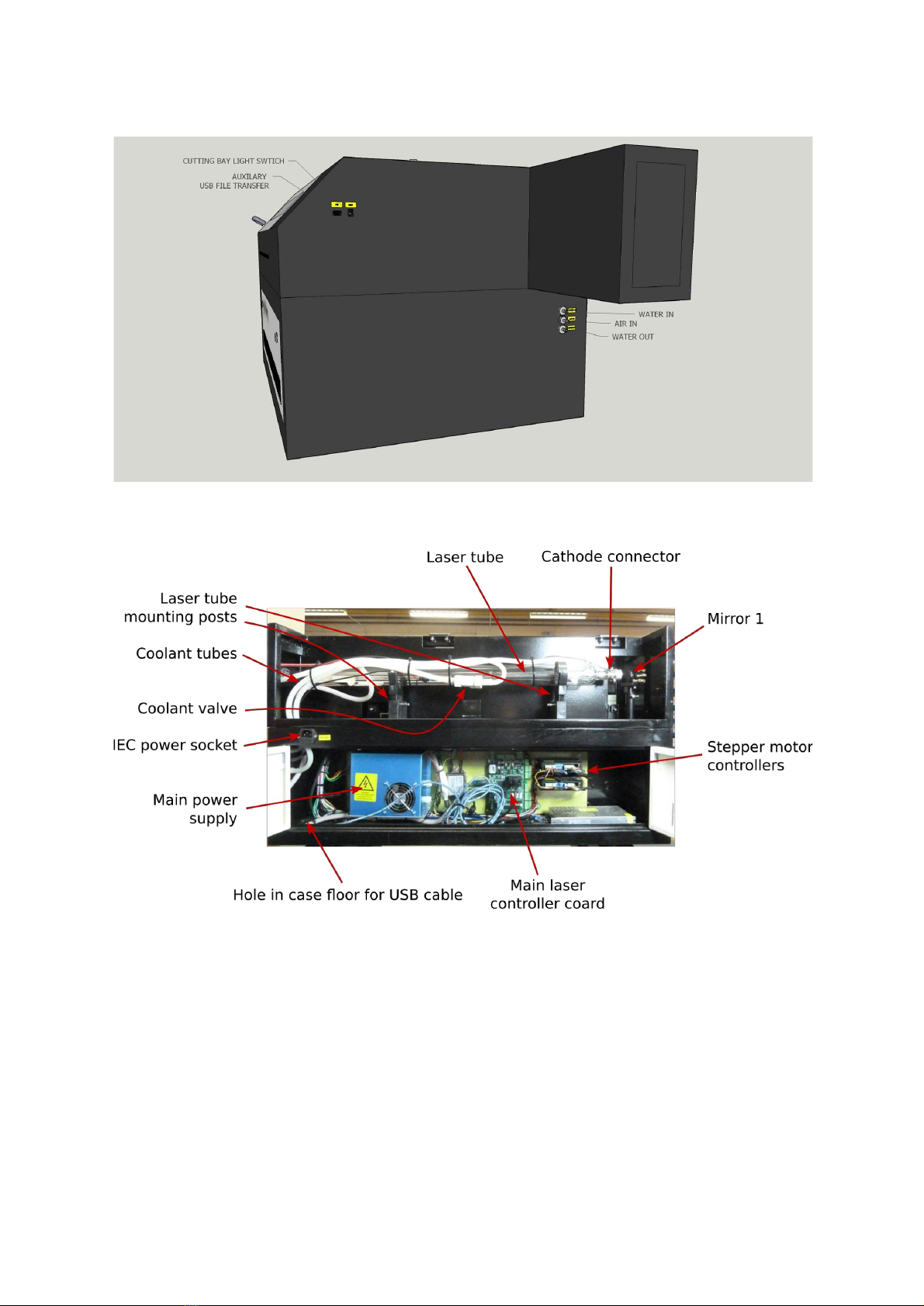

Setup and Installation

Parts List

• Blacknose A3 Laser Cutter

• Knife bed (inside cutter)

• Honeycomb bed (inside cutter)

• 40 Watt laser tube (installed in cutter)

• 4-way, 2 meter switched mains power strip

• Air assist parts:

‣Air pump

‣Bungee cord

‣1 x silicone tube

‣Brass connector

• Water pump:

‣Base plate

‣Pump

‣Brass connector

‣2 x silicone tubes

• Extractor parts:

‣Extractor fan

‣2 x 100mm ⌀ blue extraction hose

‣100mm ⌀ extraction vent adapter

‣3 x hose clamps (in plastic tool box)

‣4 x M5 hex bolts

• Workstand parts:

‣Cross bar

‣Left end

‣Right end

‣8 x 12mm M6 hex bolts & washers

• White plastic toolbox:

‣3 x hose clamps (for extraction system)

‣100mm nozzle end plate

‣3 pairs of case keys

‣Crank-type z-axis operating handle

‣Alternative Just Add Sharks z-axis operating handle

‣Leetro ‘Soft Dog’ (dongle for LaserCut software)

‣Focusing tool

‣Lockout keys to allow operation of the cutter

‣Four hex keys: 2.5mm, 3mm, 4mm and 5mm

‣Small Phillips head screwdriver

‣Mirror release tool

‣Digital thermometer

1

‣Power cable (IEC)

‣Lens cleaning cloth

1 Only provided with systems which use a water bath cooler