1-2 (No.MA232)

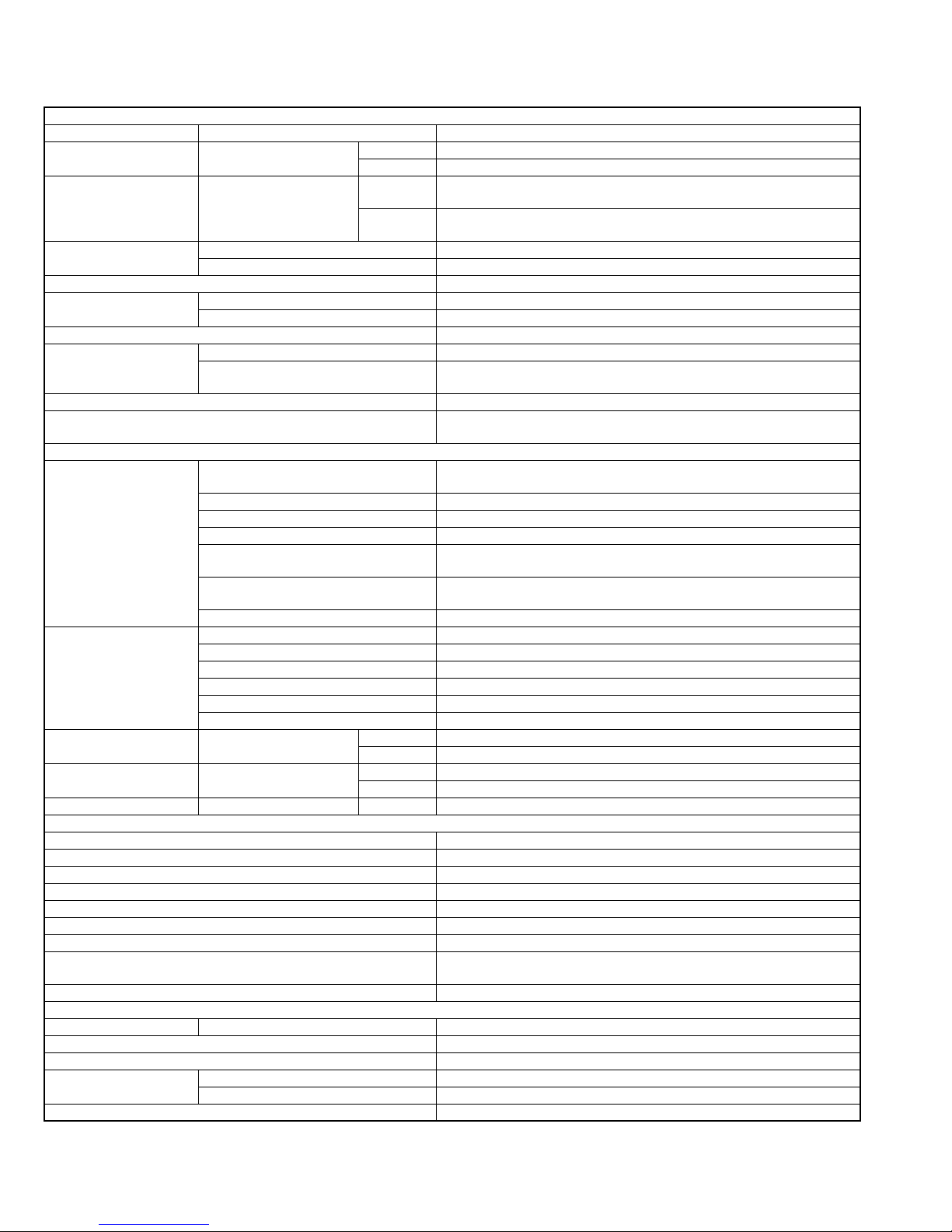

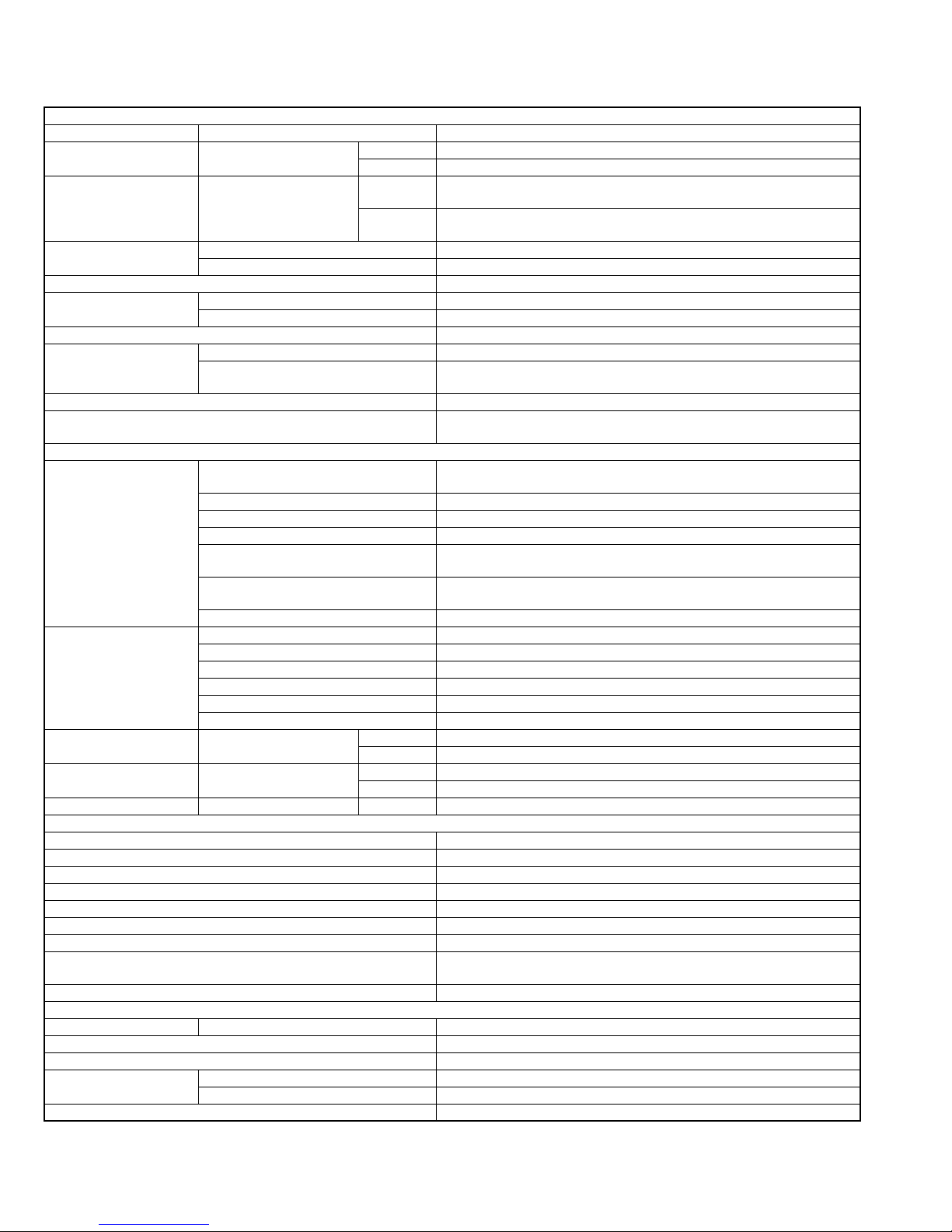

SPECIFICATION

• Microsoft and Windows Media are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

•Design and specifications are subject to change without notice.

AUDIO AMPLIFIER SECTION

Power Output KD-AR470, KD-G420 20 W RMS ×4 Channels at 4 Ωand [< or =] 1% THD+N

Maximum Power Output KD-G521, KD-G524,

KD-G525, KD-G527

Front 50 W per channel

Rear 50 W per channel

Continuous Power Output

(RMS)

KD-G521, KD-G524,

KD-G525, KD-G527

Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

harmonic distortion.

Signal to Noise Ratio KD-AR470, KD-G420 80 dBA (reference: 1 W into 4 Ω)

KD-G521, KD-G524, KD-G525, KD-G527 70 dB

Load Impedance 4 Ω(4 Ωto 8 Ωallowance)

Tone Control Range Bass ±10 dB at 100 Hz

Treble ±10 dB at 10 kHz

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance KD-AR470 4.0 V/20 kΩload (full scale)

KD-G420, KD-G521, KD-G524,

KD-G525, KD-G527

2.5 V/20 kΩload (full scale)

Output Impedance 1 kΩ

Other Terminals CD changer, Steering wheel remote input ( Only KD-G521 ), AUX (auxiliary)

input jack

TUNER SECTION

Frequency Range FM ( KD-AR470, KD-G420 ) 87.5 MHz to 107.9 MHz (with channel interval set to 100 kHz or 200 kHz)

87.5 MHz to 108.0 MHz (with channel interval set to 50 kHz)

FM ( KD-G521, KD-G524, KD-G525 ) 87.5 MHz to 108.0 MHz

FM1/FM2 ( KD-G527 ) 87.5 MHz to 108.0 MHz

FM3 ( KD-G527 ) 65.00 MHz to 74.00 MHz

AM ( KD-AR470, KD-G420 ) 530 kHz to 1 710 kHz (with channel interval set to 10 kHz)

531 kHz to 1 602 kHz (with channel interval set to 9 kHz)

AM ( KD-G521, KD-G527 ) (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

AM ( KD-G524, KD-G525 ) 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner KD-AR470, KD-G420,

KD-G524, KD-G525

Sensitivity 20 µV

Selectivity 35 dB

MW Tuner KD-G521, KD-G527 Sensitivity 20 µV

Selectivity 35 dB

LW Tuner KD-G521, KD-G527 Sensitivity 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format MPEG1/2 Audio Layer 3

Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W ×H ×D) Installation Size (approx.) 182 mm ×52 mm ×150 mm (7-3/16" ×2-1/16" ×5-15/16")

Panel Size (approx.) 188 mm ×58 mm ×11 mm (7-7/16" ×2-5/16" ×7/16")

Mass (approx.) 1.5 kg (3.3 lbs) (excluding accessories)