(No.YA354)1-9

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

NOTE:

• Make sure that the power cord is disconnected from the outlet.

• Pay special attention not to break or damage the parts.

• When removing each board, remove the connectors as required.

• Taking notes of the connecting points (connector numbers) makes service procedure manageable.

• Make sure that there is no bent or stain on the connectors before inserting, and firmly insert the connectors.

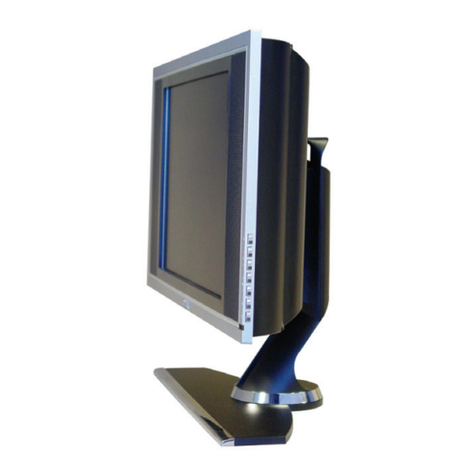

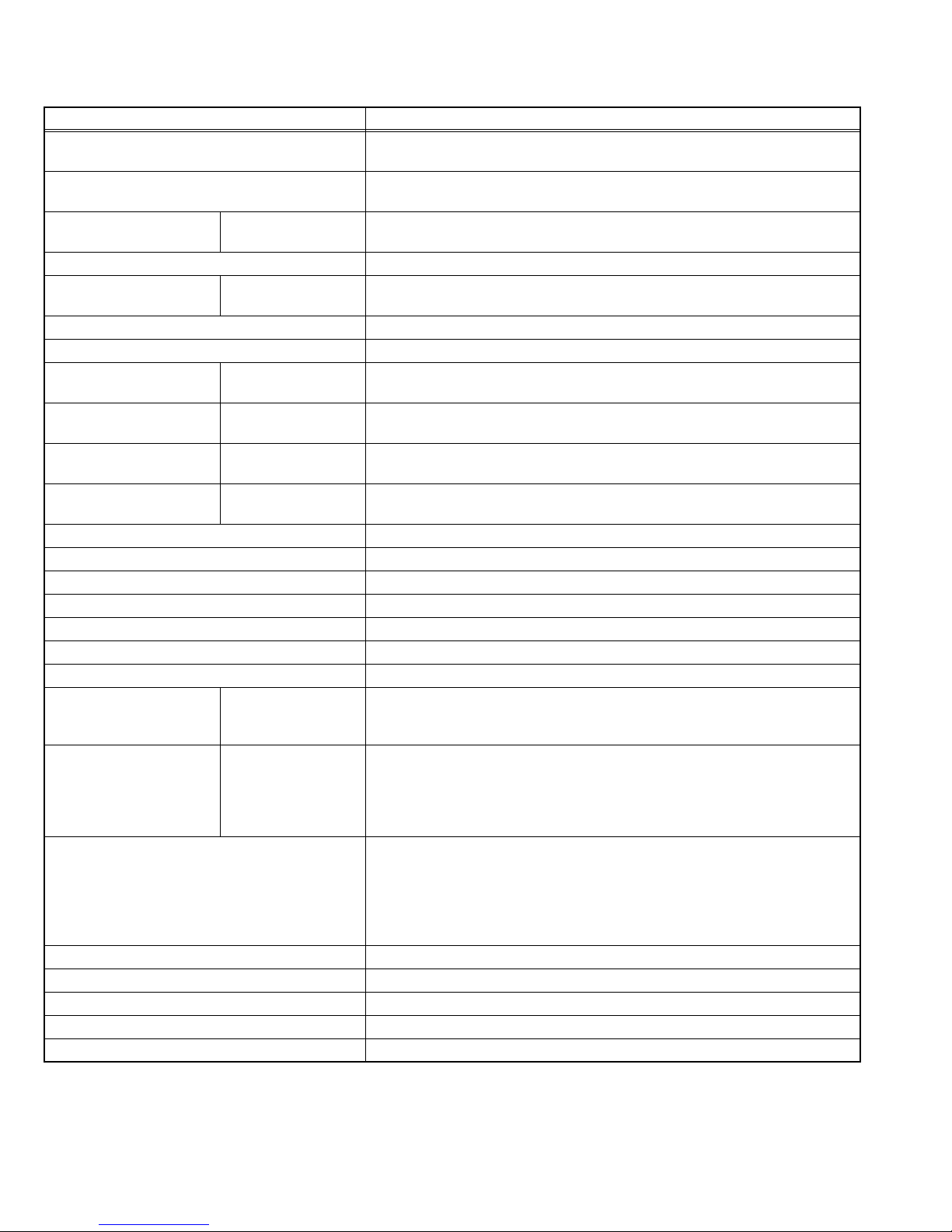

3.1.1 REMOVING THE HINGE COVER

(1) Remove the 2 screws [A].

(2) Remove the HINGE COVER.

3.1.2 REMOVING THE FOOT TOP COVER

• Remove the HINGE COVER.

(1) Remove the 2 screws [B].

(2) Pull out the FOOT TOP COVER.

3.1.3 REMOVING THE FOOT ASSEMBLY

(1) Remove the 4 screws [C].

(2) Remove the FOOT ASSEMBLY.

3.1.4 REMOVING THE THE HANDLE

• Remove the HINGE COVER.

• Remove the FOOT TOP COVER.

(1) Remove the 4 screws [D].

(2) Remove the THE HANDLE.

3.1.5 REMOVING THE BACK COVER

• Remove the FOOT ASSEMBLY.

(1) Remove the 5 screws [E].

(2) Remove the BACK COVER toward you.

NOTE:

If necessary, remove the HANDLE, SIDE AV COVER, CARD

SLOT COVER and BACK DOOR.

3.1.6 REMOVING THE SIDE CONTROL PWB

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the 2 screws [F].

(2) Remove the BUTTON FUNCTION with SIDE CONTROL

PWB.

(3) Remove the 4 craws which is fixing the SIDE CONTROL

PWB.

(4) Remove the SIDE CONTROL PWB

3.1.7 REMOVING THE METAL HANG

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the 1 screw [G].

(2) Remove the METAL HANG.

(3) Remove the opposite METAL HANG same steps.

3.1.8 REMOVING THE TERMINAL BOARD

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the 2 screws [H].

(2) Remove the TERMINAL BOARD.

3.1.9 REMOVING THE MAIN PWB

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

• Remove the TERMINAL BRACKET.

(1) Remove the 7 screws [J].

(2) Remove the MAIN PWB.

3.1.10 REMOVING THE AV JACK BRACKET

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the 2 screws [K].

(2) Remove the AV JACK BRACKET.

3.1.11 REMOVING THE AV JACK PWB

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

• Remove the AV JACK BRACKET.

(1) Remove the 2 screws [L].

(2) Remove the AV JACK PWB.

3.1.12 REMOVING THE LED PWB

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the 2 screws [M].

(2) Remove the LED PWB.

3.1.13 REMOVING THE SPEAKER

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

(1) Remove the speaker wire from speaker terminal.

(2) Remove the 2 screws [N].

(3) Remove the SPEAKER PWB.

(4) Remove the opposite speaker same steps.

3.1.14 REMOVING THE LCD PANEL UNIT

• Remove the FOOT ASSEMBLY.

• Remove the BACK COVER.

• Remove the MAIN PWB and AV JACK PWB.

(1) Remove the 4 screws [O].

(2) Remove the 5 screw [P] fixing the DISPLAY SUPPORT

and LCD PANEL UNIT.

(3) Sightly raise the both sides of the LCD PANEL UNIT by

hand from the FRONT COVER.

NOTE:

• Pay special attention not to break or damage on the FRONT

PANEL.

• The LCD PANEL UNIT is fixed to the FRONT COVER (at the

back side)by using double-side adhesive tapes. To remove

the LCD PANEL UNIT, remove the adhesive tape on the

FRONT COVER slowly.