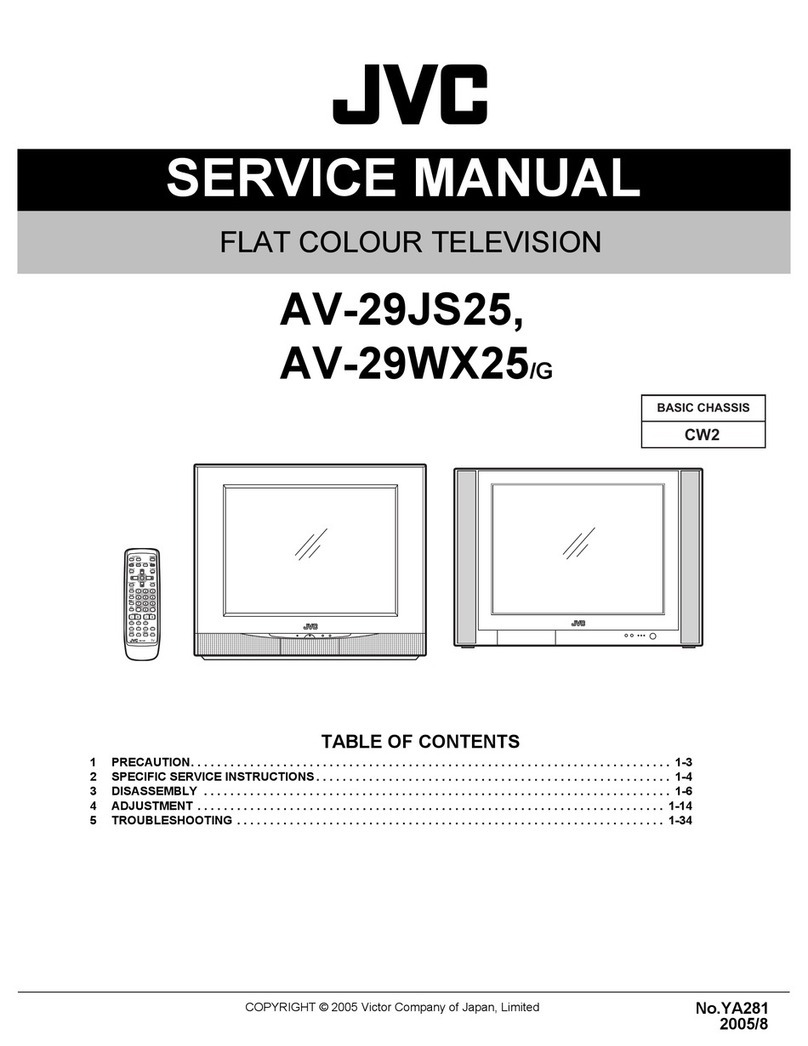

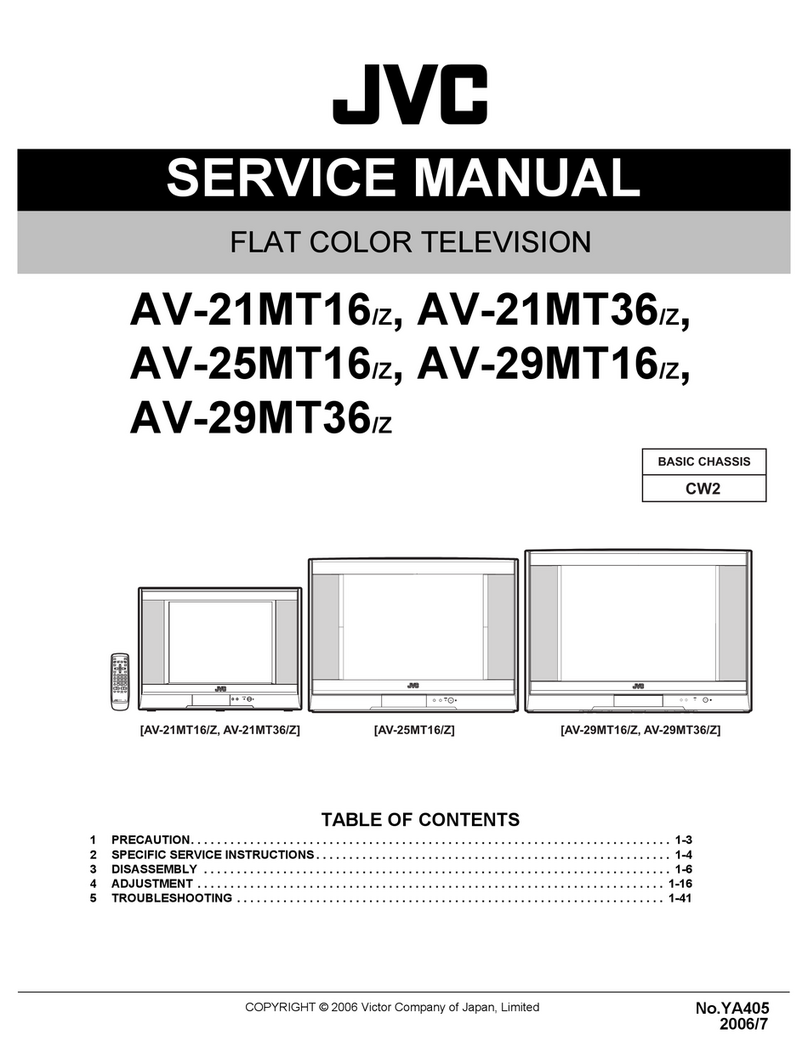

SERVICE

MANUAL

AV-2

77

o)

0

ener

CONTENTS

M

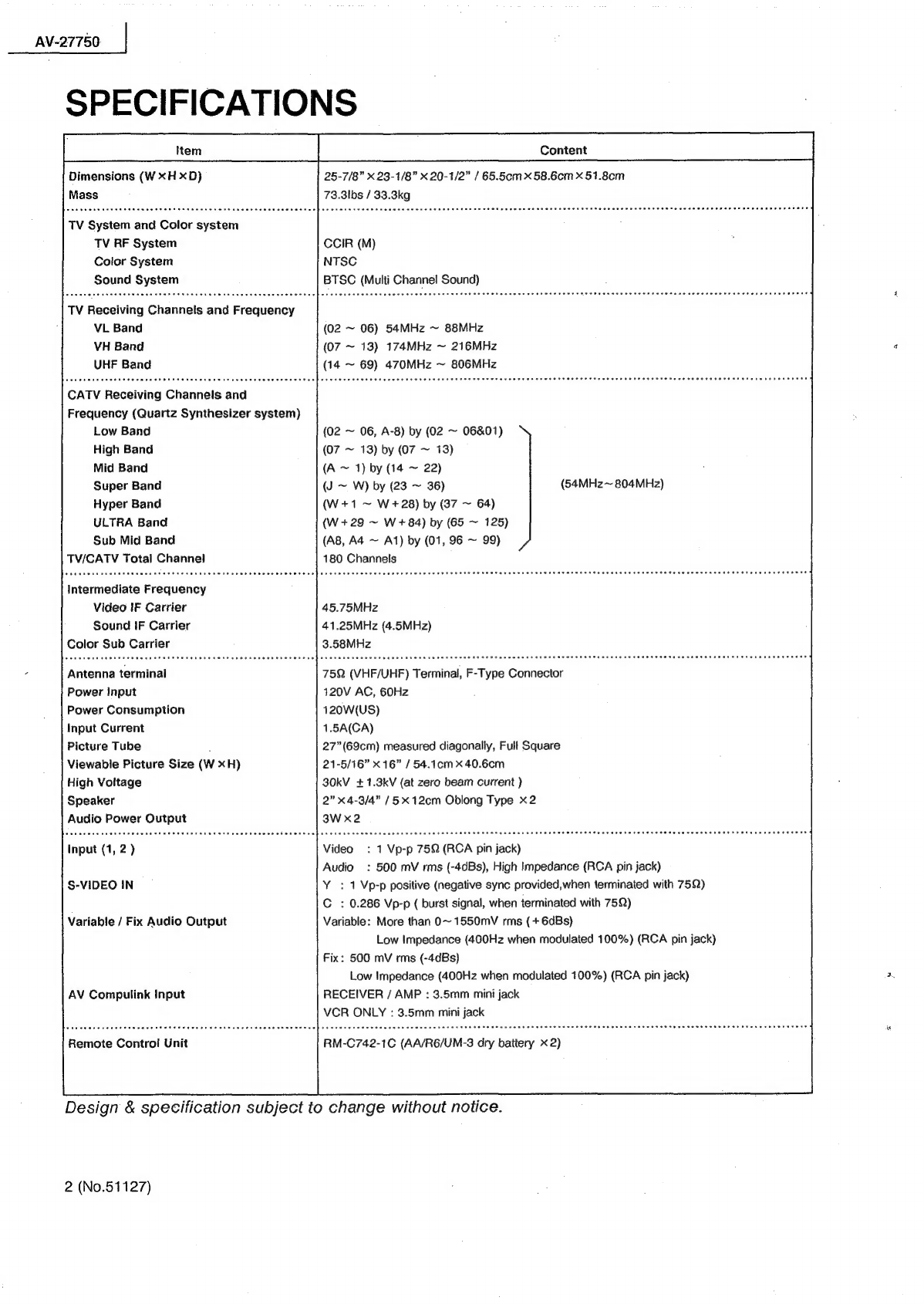

SPECIFICATIONS

.......0.0.0.0

0000s

ccc

cece

cece

cece

eee

eecceceeeunsceeucuaecnnas

2

M

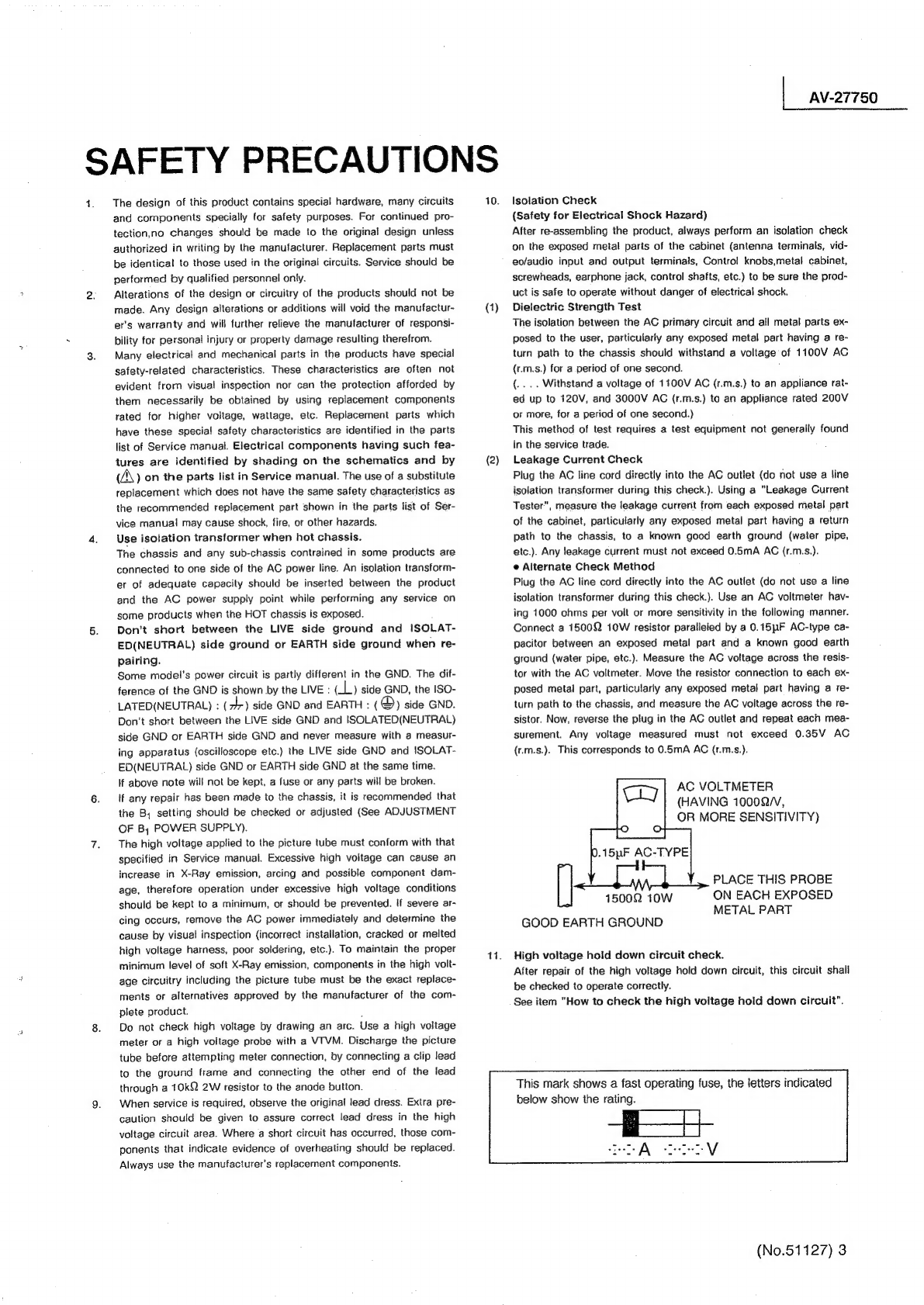

SAFETY

PRECAUTIONS

.............000

000.

cece

cece

cece

eee

eeeeeentaeeennes

3

ME

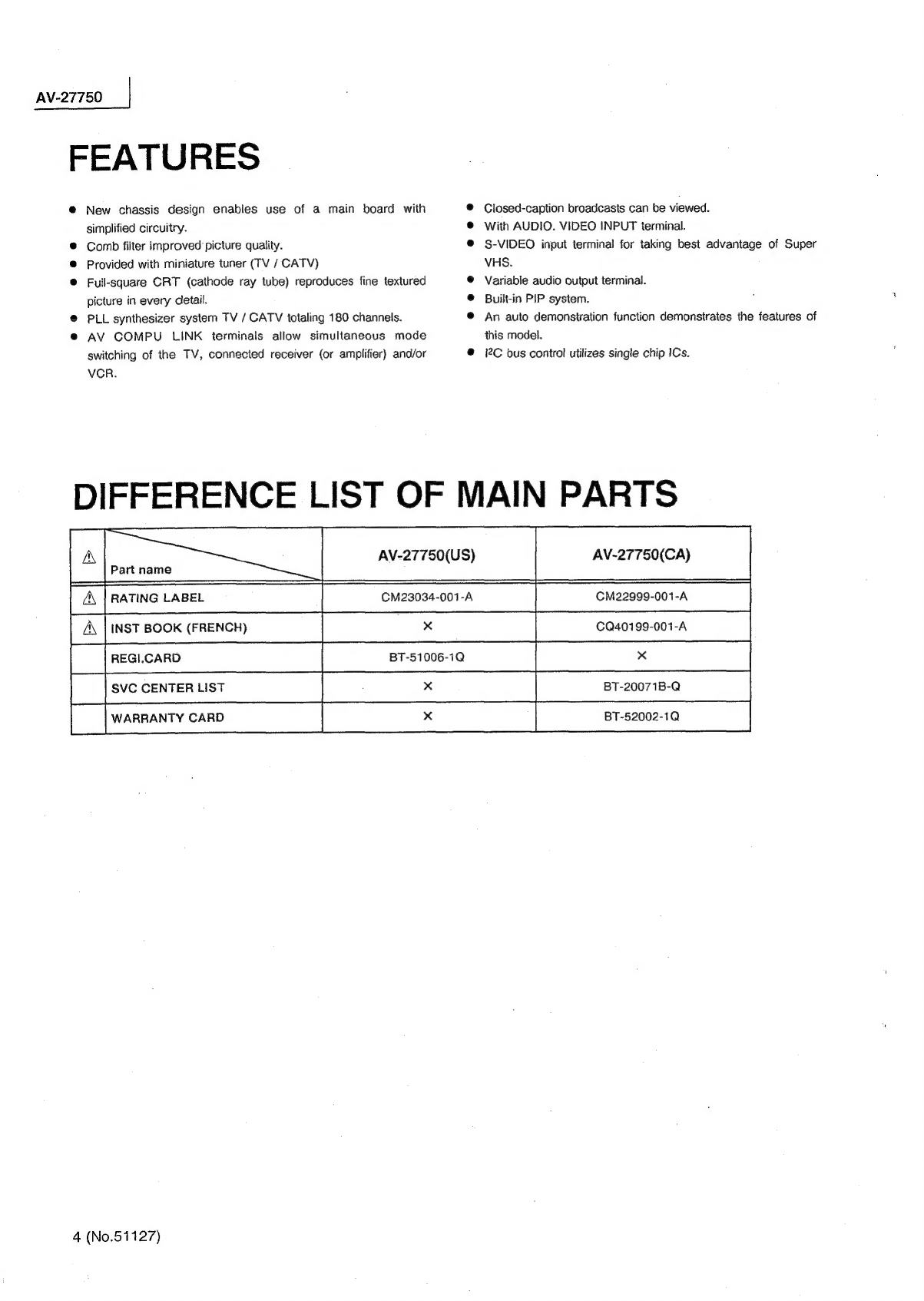

FEATURES?

3

c.04

cre

ee

2

Ghee

hah

acy

abe

cia

Wiig

athe

th

ate

oat

ben

nnn

Oa

Loe

sed

4

M

DIFFERENCE

LIST

OF

MAINPARTS

...............--0--eeeeee

ot

eee

eee

4

%

OPERATING

INSTRUCTIONS(APPENDED)

...........0...

cc

cceeeeeeeeeeeaee

1-1~1-16:

M

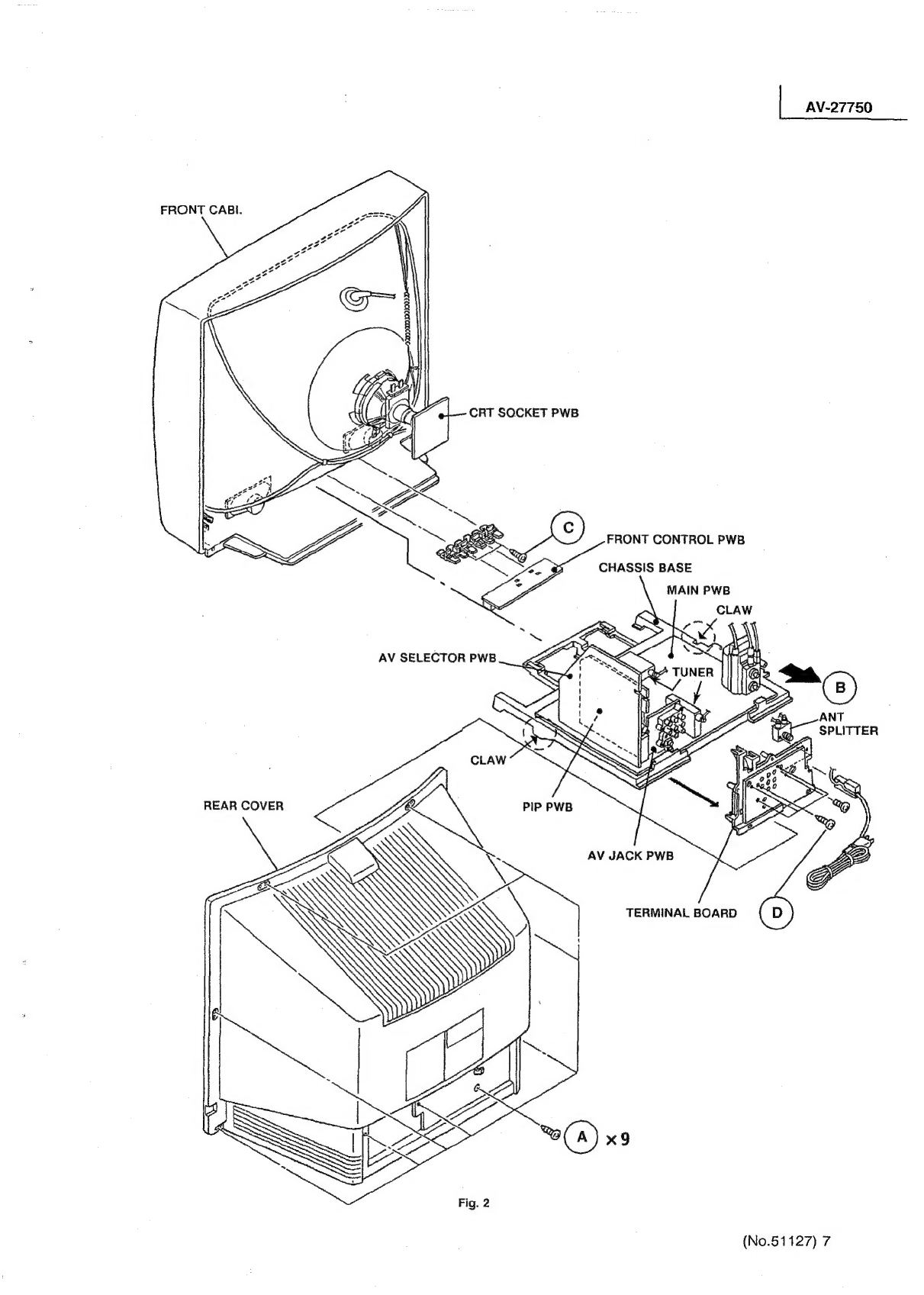

SPECIFIC

SERVICE

INSTRUCTIONS

...:.........0..0.ceeeeeeeee

Dhaai

aged

ates

5

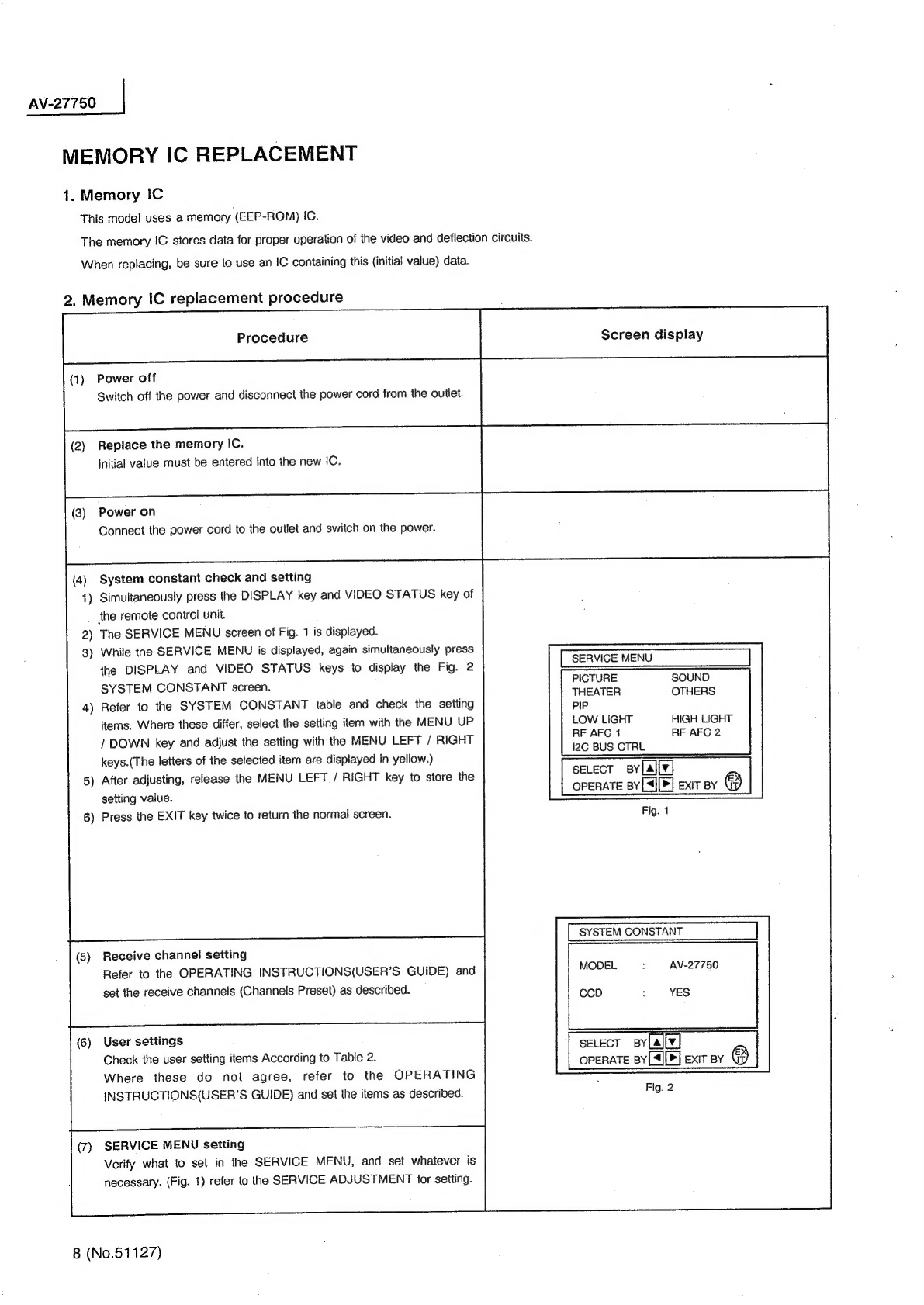

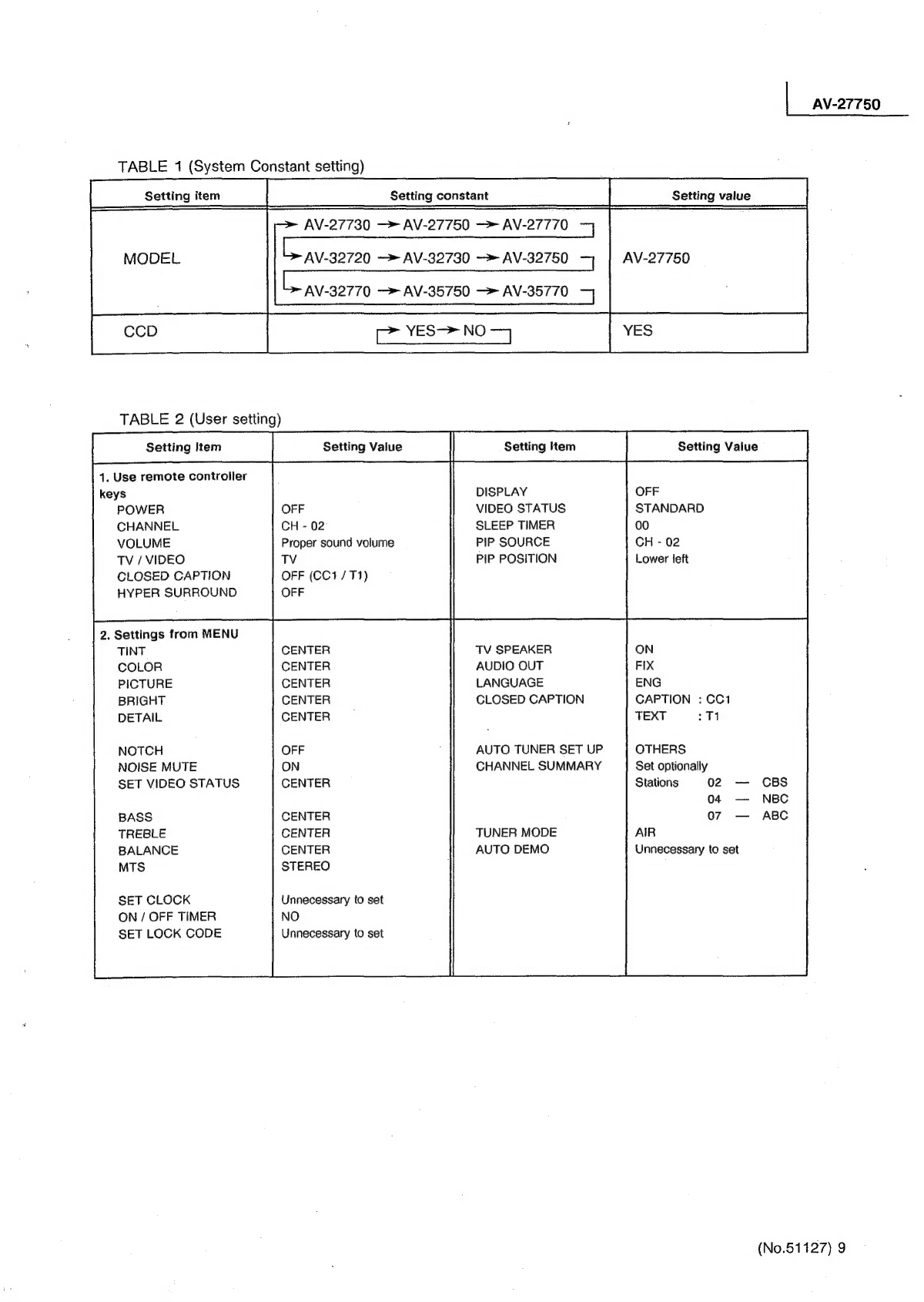

M

SERVICE

ADJUSTMENTS

....

00...

0c

cece

cence

eeeeeveeennees

10

%&

STANDARD

CIRCUIT

DIAGRAM(APPENDED)

................-----

S

sbaeatn

sas

2-1~2-24

BM

PARTS

(IS

cre

aid

nh

oe

Hs

naeeaet

car

iuteiatok:

SR

aCe

e

ie

at

ane

tae

25

No.51127

COPYRIGHT

©

1996

VICTOR

COMPANY

OF

JAPAN,LTD.

June

1996