No. 52130 9

AV-14F704

2-7: VERTICAL SIZE

1. Receive the monoscope pattern.

2. Using the remote control, set the brightness and contrast to

normal position.

3. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (07) on the remote control to select “V. SIZE”.

4. Press the VOL. UP/DOWN button on the remote control until the

SHIFT quantity of the OVER SCAN on upside and downside

becomes 9 ± 2%.

2-8: VERTICAL LINEARITY

NOTE: Adjust after performing adjustments in section 2-7.

After the adjustment of Vertical Linearity, reconfirm the

Vertical Position and Vertical Size adjustments.

1. Receive the monoscope pattern.

2. Using the remote control, set the brightness and contrast to

normal position.

3. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (08) on the remote control to select “V. LIN”.

4. Press the VOL. UP/DOWN button on the remote control until the

SHIFT quantity of the OVER SCAN on upside and downside

becomes minimum.

2-9: LEVEL

1. Receive the VHF HIGH (70dB).

2. Connect the AC voltmeter to the pin 6 of CP101.

3. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (33) on the remote control to select “LEVEL”.

4. Press the VOL. UP/DOWN button on the remote control until the

AC voltmeter is 75 ± 2mV.

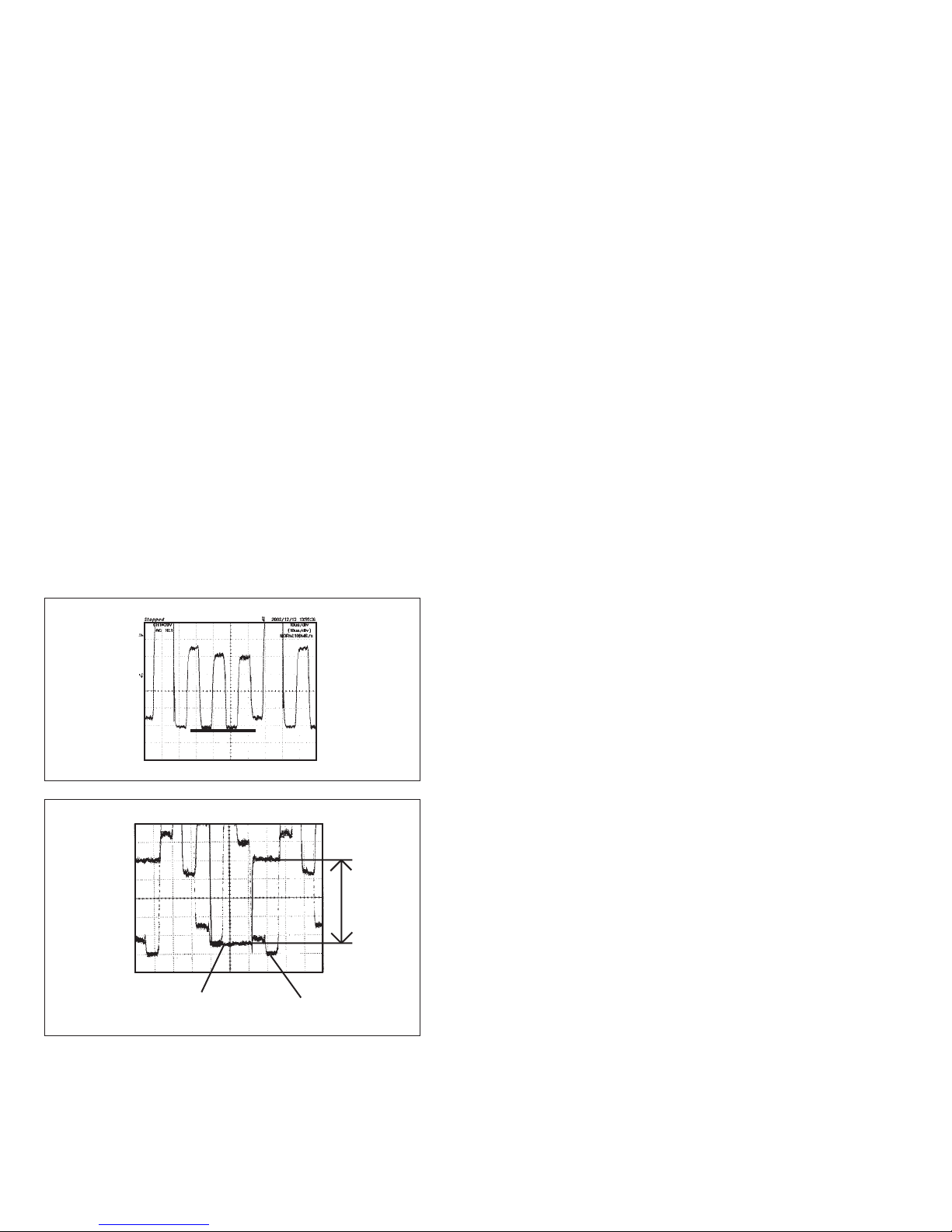

2-10: OSD HORIZONTAL

1. Activate the adjustment mode display of Fig. 1-1.

2. Press the VOL. UP/DOWN button on the remote control until the

difference of A and B becomes minimum.

(Refer to Fig. 2-1)

2-11: SEPARATION 1, 2

Please do the method (1) or method (2) adjustment.

Method (1)

1. Set the multi-sound signal generator for each different Lch and

R-ch frequency (Ex. L-ch=2KHz, R-ch=400Hz) and receive the

RF.

2. Connect the oscilloscope to the Audio Out Jack.

3. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (34) on the remote control to select “SEP1”.

4. Press the VOL. UP/DOWN button on the remote control to adjust

it until the audio output wave becomes a fine sine wave.

5. Press the CH UP button once the set to “SEP 2” mode.

Then perform the above adjustment 4.

Method (2)

1. Set the multi-sound signal generator L-ch=1KHz, R-ch =Non

input and receive the RF.

2. Connect the oscilloscope to the Audio Out Jack (R-ch).

3. Press the AUDIO SELECT button on the remote control to set to

the stereo mode.

4. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (34) on the remote control to select “SEP 1”.

5. Press the VOL. UP/DOWN button on the remote control to adjust

it until the R-ch output becomes minimum.

6. Set the multi-sound signal generator L-ch=Non input, R-ch=1KHz

and receive the RF.

7. Connect the oscilloscope to the Audio Out Jack (L-ch).

8. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (35) on the remote control to select “SEP 2”.

9. Press the VOL. UP/DOWN button on the remote control to adjust

it until the L-ch output becomes minimum.

2-12: BRIGHT CENTER

1. Receive the monoscope pattern. (RF Input)

2. Using the remote control, set the brightness and contrast to

normal position.

3. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (16) on the remote control to select “BRI. CENT”.

4. Press the VOL. UP/DOWN button on the remote control until the

white 15% is starting to be visible.

5. Receive the monoscope pattern. (Audio Video Input)

6. Press the TV/VCR button on the remote control to set to the AV

mode. Then perform the above adjustments 2~4.

7. Press the TV/VCR button on the remote control to set to the CS

mode.

8. Activate the adjustment mode display of Fig. 1-1 and press the

channel button (16) on the remote control to select “BRI. CENT”.

9. Press the VOL. UP/DOWN button on the remote control to set

the same step numbers as the AV.

Fig. 2-1

TV

00 OSD 35

A B