1-6 (No.YA225)

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

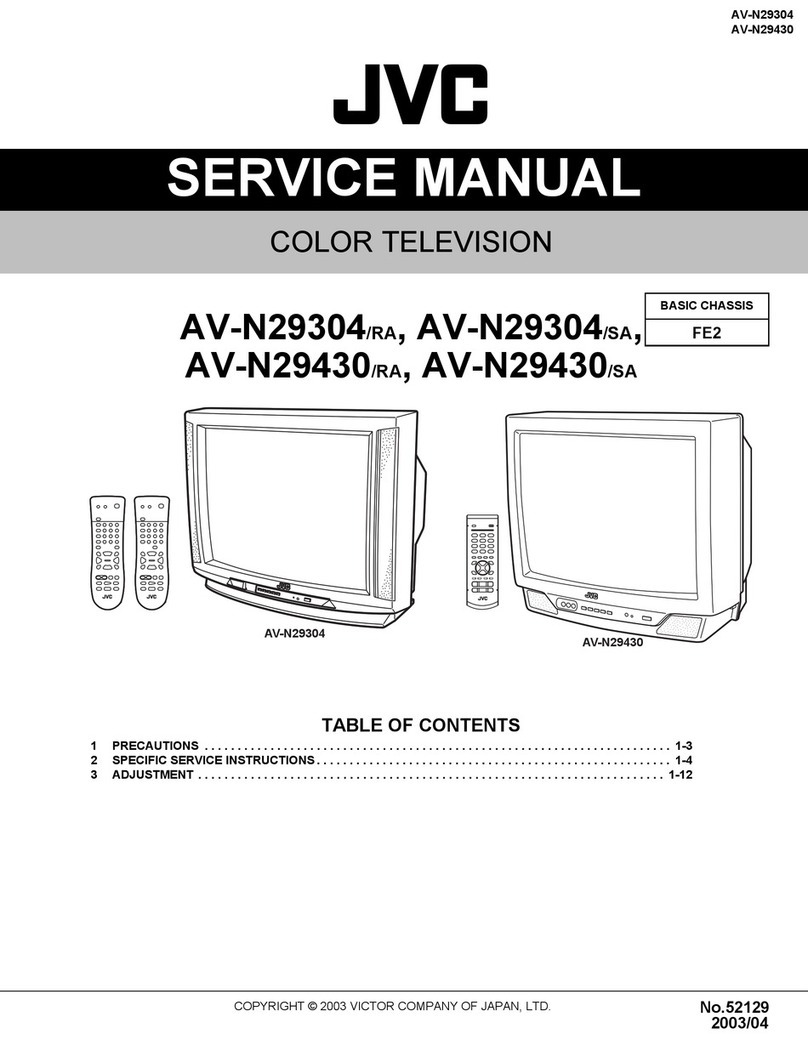

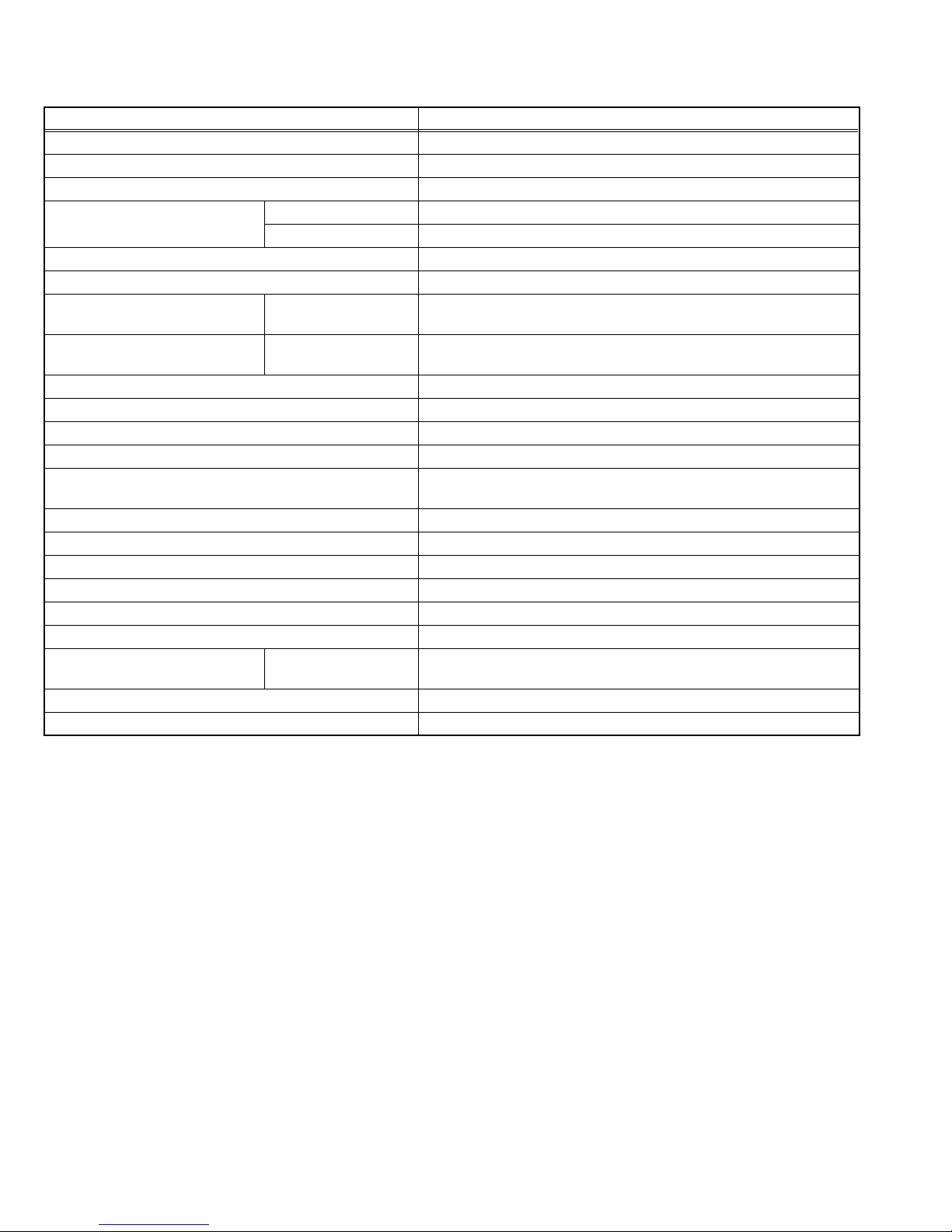

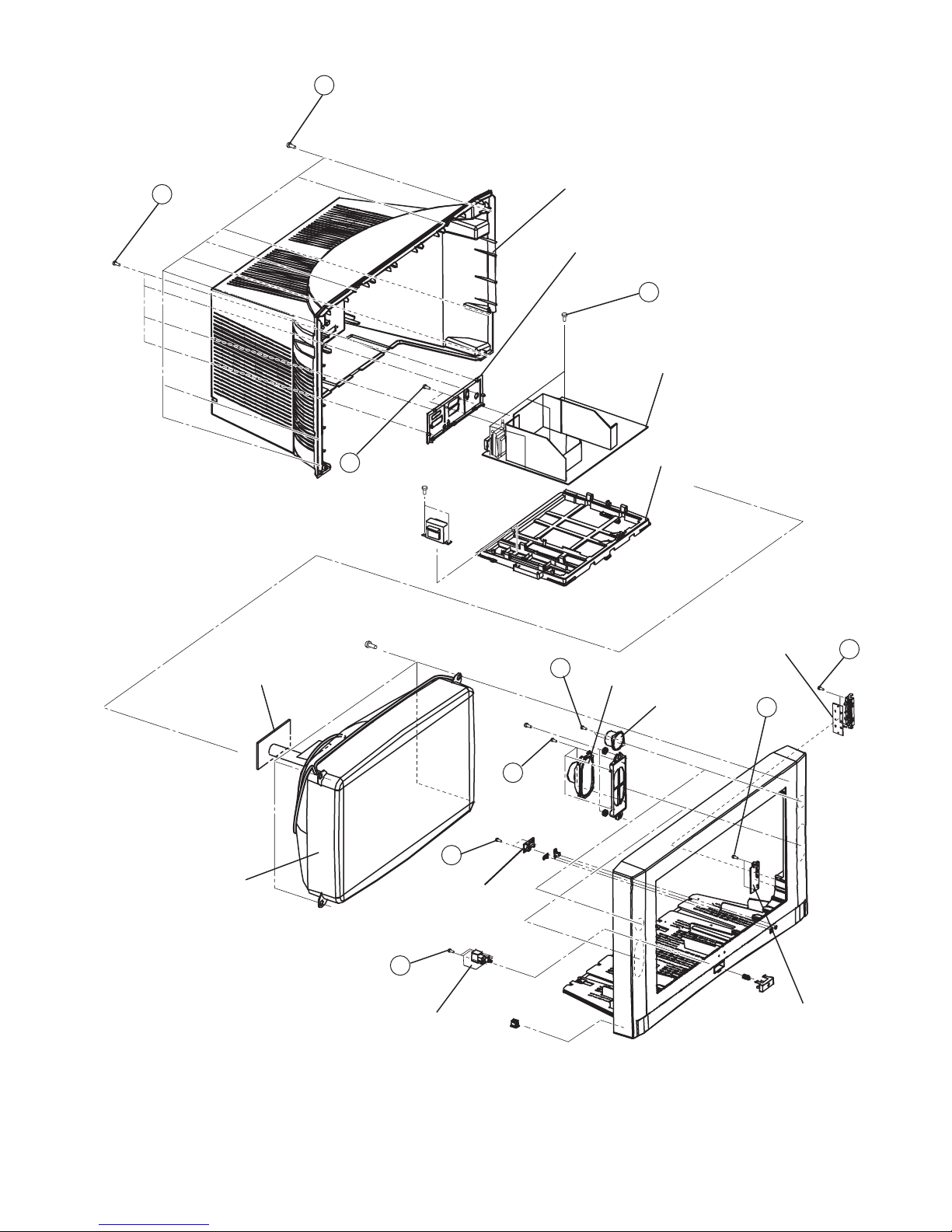

3.1.1 REMOVING THE REAR COVER

(1) Unplug the power cord.

(2) Remove the 8 screws [A].

(3) Remove the 4 screws [B].

(4) Withdraw the REAR COVER toward you.

3.1.2 REMOVING THE BACK DOOR

• Remove the REAR COVER.

(1) Remove the 2 screws [C].

(2) Withdraw the BACK DOOR toward you.

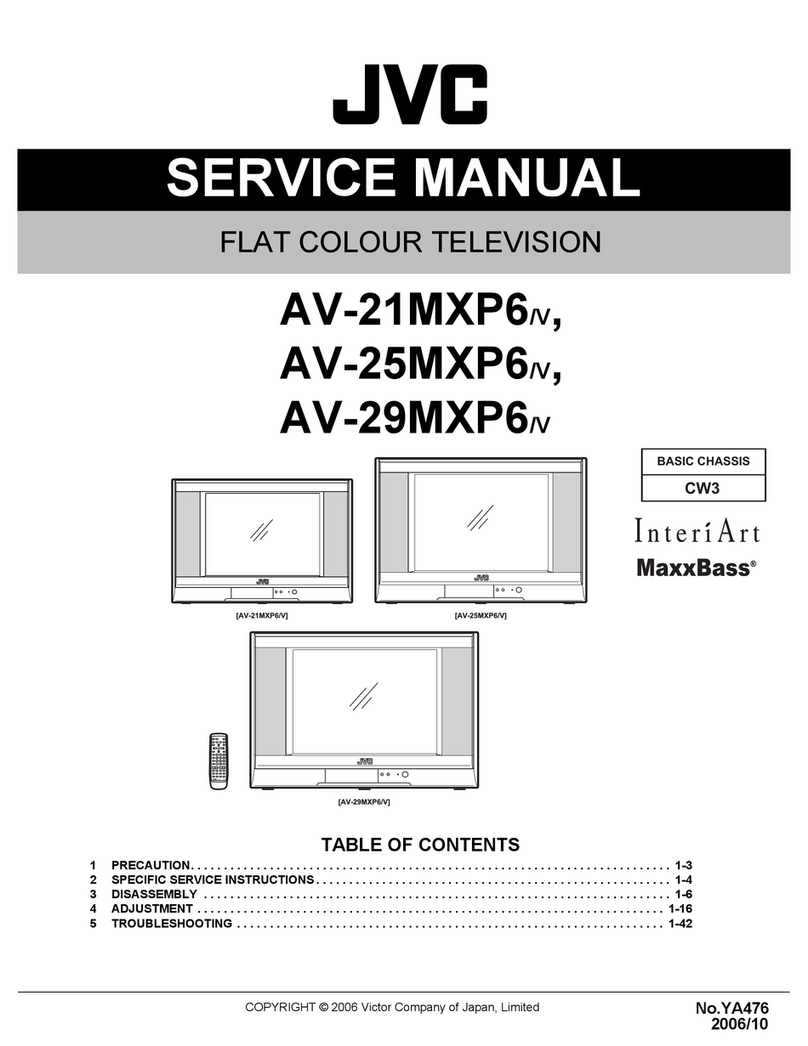

3.1.3 REMOVING THE SPEAKER and TWEETER

• Remove the REAR COVER.

(1) Remove the 4 screws [D], and remove the SPEAKER.

(2) Remove the other hand SPEAKER in the same steps.

(3) Remove the 2 screws [E], and remove the TWEETER.

(4) Remove the other hand TWEETER in the same steps.

3.1.4 REMOVING THE MAIN PWB

• Remove the REAR COVER.

• Remove the BACK DOOR.

(1) Remove the 4 screws [F].

(2) Slightly raise the both sides of the MAIN PWB by hand and

withdraw the MAIN PWB backward.

[CAUTION]

If necessary, take off the wire clamp, connectors etc.

Be careful enough when developing a MAIN PWB.

3.1.5 REMOVING THE SIDE CONTROL PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [G].

(2) Remove the SIDE CONTROL PWB.

3.1.6 REMOVING THE FRONT AV & HEADPHONE JACK

PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [H].

(2) Remove the FRONT AV & HEADPHONE JACK PWB.

3.1.7 REMOVING THE POWER SWITCH PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [I], and remove the POWER

SWITCH PWB.

3.1.8 REMOVING THE LED PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [J], and remove the LED PWB.

3.1.9 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the PW Board. (Refer to REMOVING THE MAIN

PWB).

(2) Erect the PW Board vertically so that you can easily check

the back side of the PWB.

[CAUTION]

• When erecting the PW Board, be careful so that there will be

no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

• When conducting a check with power supplied, be sure to

confirm that the CRT EARTH WIRE (BRAIDED ASS'Y) is

connected to the CRT SOCKET PWB.

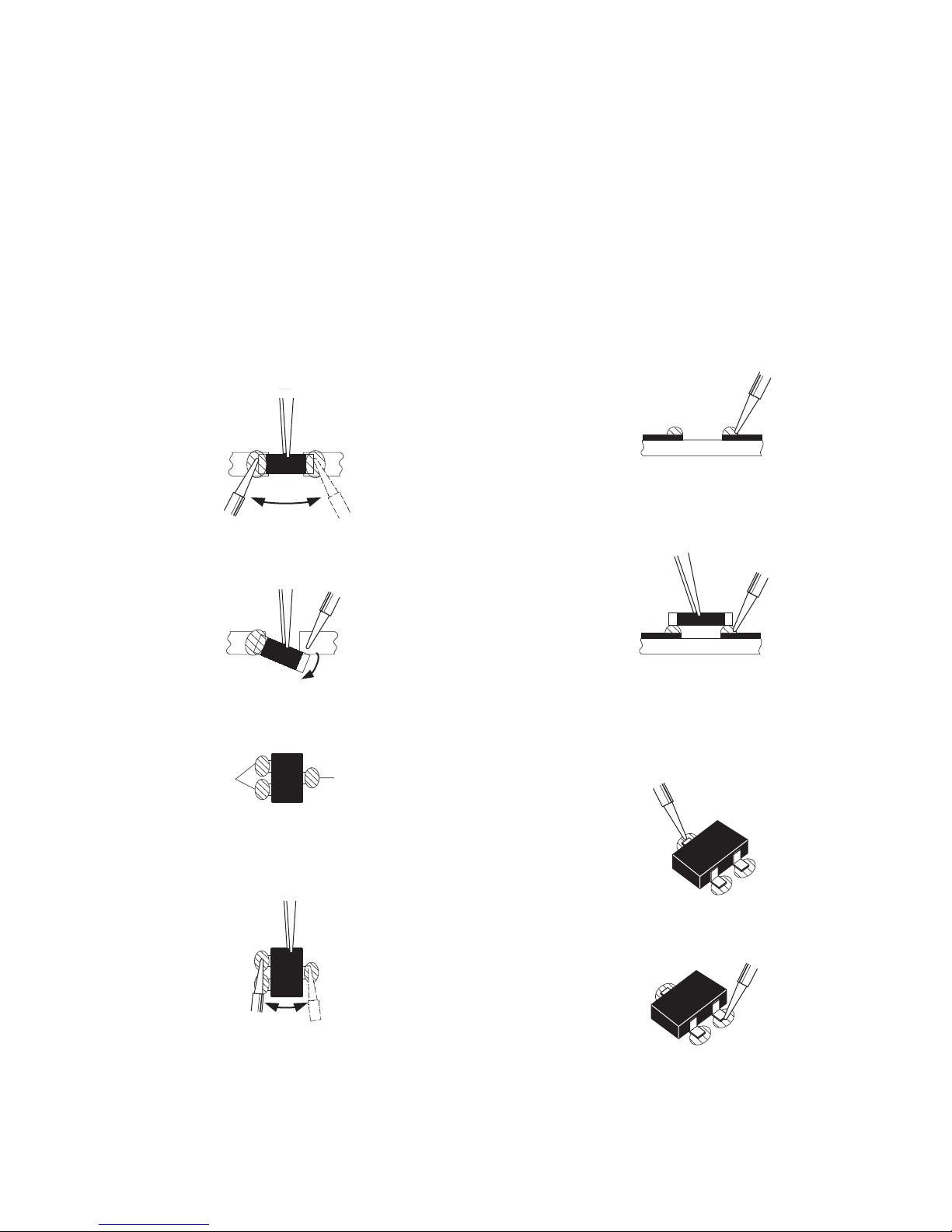

3.1.10 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.