Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 DISASSEMBLY FLOW CHART ............................................................ 1-1

1.2 HOW TO READ THE DISASSEMBLY AND ASSEMBLY ...................... 1-1

1.3 DISASSEMBLY/ASSEMBLY METHOD ................................................ 1-1

1.4 SERVICE POSITION ............................................................................ 1-4

1.4.1 How to take out the Mechanism and Main board assemblies ......... 1-4

1.4.2 Precautions for cassette loading in the "SERVICE POSITION" ...... 1-5

1.4.3 Cassette loading and ejection methods

in the “SERVICE POSITION”(See Fig. 1-4-3). ................................ 1-5

1.5 MECHANISM SERVICE MODE ........................................................... 1-5

1.5.1 How to set the "MECHANISM SERVICE MODE" ............................ 1-5

1.6 EMERGENCY DISPLAY FUNCTION ................................................... 1-6

1.6.1 Displaying the emergency information ............................................ 1-6

1.6.2 Clearing the emergency history ....................................................... 1-6

1.6.3 Emergency content description ....................................................... 1-7

1.6.4 Emergency detail information 1...................................................... 1-8

1.6.5 Emergency detail information 2..................................................... 1-9

1.7 SERVICING THE VIDEO NAVIGATION FUNCTION ......................... 1-10

1.7.1 Copying the video navigation data ................................................ 1-10

1.7.2 Erasing the video navigation data (Initialization) ........................... 1-11

1.7.3 Factory setting level during shipment ........................................... 1-11

2. MECHANISM ADJUSTMENT

2.1 BEFORE STARTING REPAIR AND ADJUSTMENT............................. 2-1

2.1.1 Precautions ...................................................................................... 2-1

2.1.2 Checking for Proper Mechanical Operations ...................................2-1

2.1.3 Manually Removing the Cassette Tape ........................................... 2-1

2.1.4 Jigs and Tools Required for Adjustment .......................................... 2-2

2.1.5 Maintenance and Inspection ............................................................ 2-3

2.2 REPLACEMENT OF MAJOR PARTS .................................................. 2-6

2.2.1 Before Starting Disassembling (Phase matching between

mechanical parts) ............................................................................ 2-6

2.2.2 How to Set the Mechanism Assembling Mode ................................ 2-6

2.2.3 Cassette Holder Assembly .............................................................. 2-6

2.2.4 Pinch Roller Arm Assembly ............................................................. 2-8

2.2.5 Guide Arm Assembly and Press Lever Assembly ............................ 2-8

2.2.6 Audio Control Head ......................................................................... 2-8

2.2.7 Loading Motor .................................................................................. 2-8

2.2.8 Capstan Motor ................................................................................. 2-9

2.2.9 Pole Base Assembly (supply or take-up side) ................................. 2-9

2.2.10 Rotary Encoder ........................................................................... 2-10

2.2.11 Clutch Unit .................................................................................. 2-10

2.2.12

Change Lever Assembly, Direct Gear, Clutch Gear and Coupling Gear ......

2-10

2.2.13 Link Lever ................................................................................... 2-11

2.2.14 Cassette Gear, Control Cam and Worm Gear ............................ 2-11

2.2.15 Control Plate ............................................................................... 2-11

2.2.16

Loading Arm Gear (supply or take-up side) and Loading Arm Gear Shaft...

2-12

2.2.17 Take-up Lever, Take-up Head and Control Plate Guide ............. 2-13

2.2.18 Capstan Brake Assembly .......................................................... 2-13

2.2.19 Sub Brake Assembly (take-up side) ........................................... 2-13

2.2.20 Main Brake Assembly (take-up side), Reel Disk

(take-up side) and Main Brake Assembly (supply side).............. 2-13

2.2.21 Tension Brake Assembly, Reel Disk (supply side) and

Tension Arm Assembly ............................................................... 2-14

2.2.22 Idler Lever, Idler Arm Assembly .................................................. 2-14

2.2.23 Stator Assembly .......................................................................... 2-14

2.2.24 Rotor Assembly .......................................................................... 2-14

2.2.25 Upper Drum Assembly ................................................................ 2-15

2.3 COMPATIBILITY ADJUSTMENT ........................................................ 2-16

2.3.1 Checking/Adjustment of FM Waveform Linearity ........................... 2-16

2.3.2

Checking/Adjustment of the Height and Tilt of the Audio Control Head ....

2-17

2.3.3

Checking/Adjustment of the Audio Control Head Phase (X-Value) .....

2-17

2.3.4 Checking/Adjustment of the Standard Tracking Preset ................. 2-18

2.3.5 Checking/Adjustment of the Tension Pole Position ....................... 2-18

3. ELECTRICAL ADJUSTMENT

3.1 PRECAUTION ..................................................................................... 3-1

3.1.1 Required test equipments .............................................................. 3-1

3.1.2 Required adjustment tools ............................................................... 3-1

TABLE OF CONTENTS

Section Title Page Section Title Page

3.1.3 Color (colour) bar signal,Color (colour) bar pattern........................ 3-1

3.1.4 Switch settings and standard precautions ....................................... 3-1

3.1.5 EVR Adjustment .............................................................................. 3-1

3.2 SERVO CIRCUIT .................................................................................. 3-2

3.2.1 Switching point ................................................................................ 3-2

3.2.2 Slow tracking preset ........................................................................ 3-2

3.2.3 Dynamic Drum preset ...................................................................... 3-2

3.3 VIDEO CIRCUIT ................................................................................... 3-3

3.3.1 D/A level .......................................................................................... 3-3

3.3.2 EE Y level ........................................................................................ 3-3

3.3.3 PB Y level (S-VHS / VHS) ............................................................... 3-3

3.3.4 REC color (colour) level ................................................................... 3-4

3.3.5 Video EQ (Frequency response) ..................................................... 3-4

3.3.6 AUTO PICTURE initial setting ......................................................... 3-5

3.4 AUDIO CIRCUIT ................................................................................... 3-5

3.4.1 Audio REC FM ................................................................................. 3-5

3.5 SYSCON CIRCUIT ............................................................................... 3-5

3.5.1 Timer clock ...................................................................................... 3-5

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .......................................................... 4-1

CIRCUIT BOARD NOTES ........................................................................... 4-2

4.1 BOARD INTERCONNECTIONS .......................................................... 4-3

4.2

VIDEO/AUDIO AND AUDIO ERASE SCHEMATIC DIAGRAMS ............ 4-5

4.3 VSC SCHEMATIC DIAGRAM ................................................................. 4-7

4.4 SYSTEM CONTROL SCHEMATIC DIAGRAM ....................................... 4-9

4.5 SWITCHING REGULATOR SCHEMATIC DIAGRAM .......................... 4-11

4.6 TUNER SCHEMATIC DIAGRAM .......................................................... 4-13

4.7 CONNECTION SCHEMATIC DIAGRAM .............................................. 4-15

4.8 3D DIGITAL/2M SCHEMATIC DIAGRAM ............................................. 4-17

4.9 TERMINAL SCHEMATIC DIAGRAM .................................................... 4-19

4.10

DEMODULATOR SCHEMATIC DIAGRAM ..................................... 4-21

4.11 S-SUB SCHEMATIC DIAGRAM ...................................................... 4-23

4.12 NAVIGATION SCHEMATIC DIAGRAM [LPB10108-001*] ............... 4-25

4.13 NAVIGATION SCHEMATIC DIAGRAM [LPB10108-002*] ............... 4-27

4.14 SW/DISPLAY AND REC SAFETY SCHEMATIC DIAGRAMS ........ 4-29

4.15 3D DIGITAL/2M AND S-SUB CIRCUIT BOARDS ........................... 4-31

4.16 TERMINAL CIRCUIT BOARD .......................................................... 4-32

4.17 MAIN, A/C HEAD, AUDIO ERASE AND LOADING MOTOR

CIRCUIT BOARDS ........................................................................... 4-33

4.18 NAVIGATION CIRCUIT BOARD ...................................................... 4-36

4.19

DEMODULATOR, SW/DISPLAY AND REC SAFETY CIRCUIT BOARDS .

4-37

4.20 FDP GRID ASSIGNMENT AND ANODE CONNECTION ............... 4-39

4.21 REMOTE CONTROL AND MEMBRANE DOOR

SCHEMATIC DIAGRAMS ................................................................ 4-40

4.22 WAVEFORMS .................................................................................. 4-41

4.23 VOLTAGE CHARTS ......................................................................... 4-43

4.24 CPU PIN FUNCTION ....................................................................... 4-45

4.25 SYSTEM CONTROL BLOCK DIAGRAM ......................................... 4-47

4.26 VIDEO BLOCK DIAGRAM ............................................................... 4-49

4.27 AUDIO BLOCK DIAGRAM ...............................................................4-53

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ............................... 5-1

5.2 CABINET AND CHASSIS ASSEMBLY <M2> ...................................... 5-2

5.3 MECHANISM ASSEMBLY <M4> ......................................................... 5-4

5.4 ELECTRICAL PARTS LIST .................................................................. 5-6

MAIN BOARD ASSEMBLY <03> .......................................................... 5-6

3D DIGITAL/2M BOARD ASSEMBLY <05> ........................................ 5-13

TERMINAL BOARD ASSEMBLY <06> ............................................... 5-14

AUDIO CONTROL HEAD BOARD ASSEMBLY <12> ........................ 5-16

DEMOD BOARD ASSEMBLY <14> ................................................... 5-16

S-SUB BOARD ASSEMBLY <15> ...................................................... 5-17

NAVIGATION BOARD ASSEMBLY <19> [LPB10108-001*] ............... 5-17

NAVIGATION BOARD ASSEMBLY <19> [LPB10108-002*] ............... 5-18

DISPLAY BOARD ASSEMBLY <28> .................................................. 5-19

REC SAFETY BOARD ASSEMBLY <32> .......................................... 5-20

AUDIO ERASE BOARD ASSEMBLY <46> ........................................ 5-20

LOADING MOTOR BOARD ASSEMBLY <55> .................................. 5-20

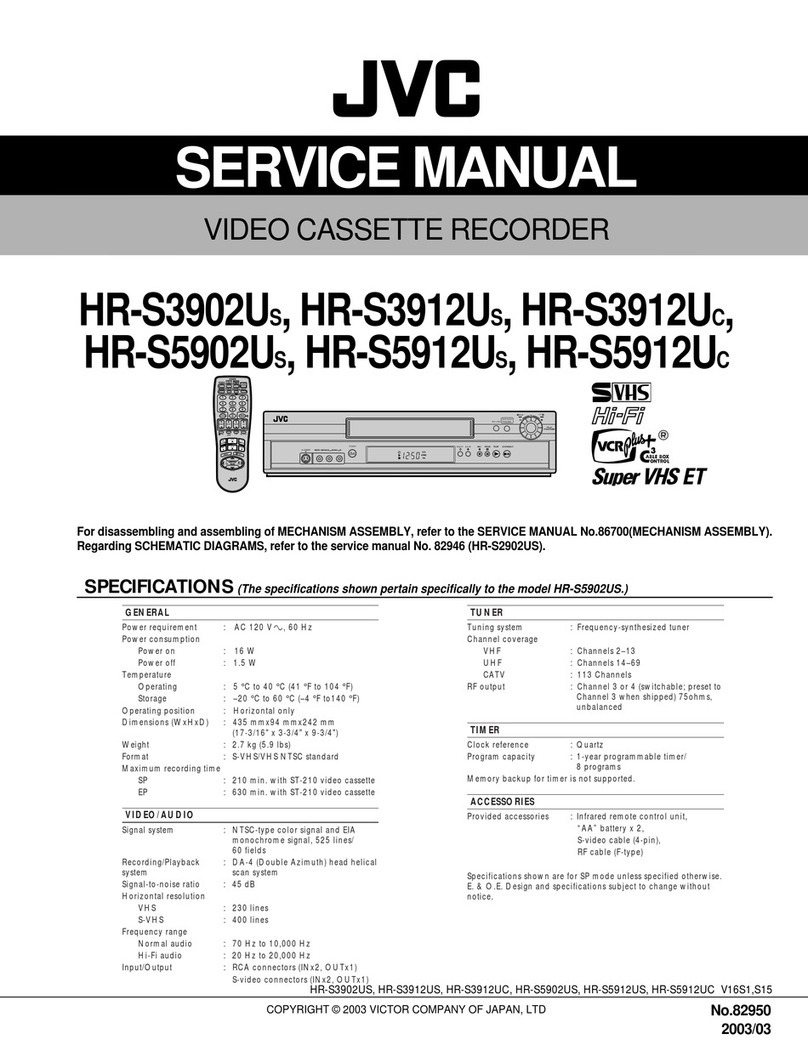

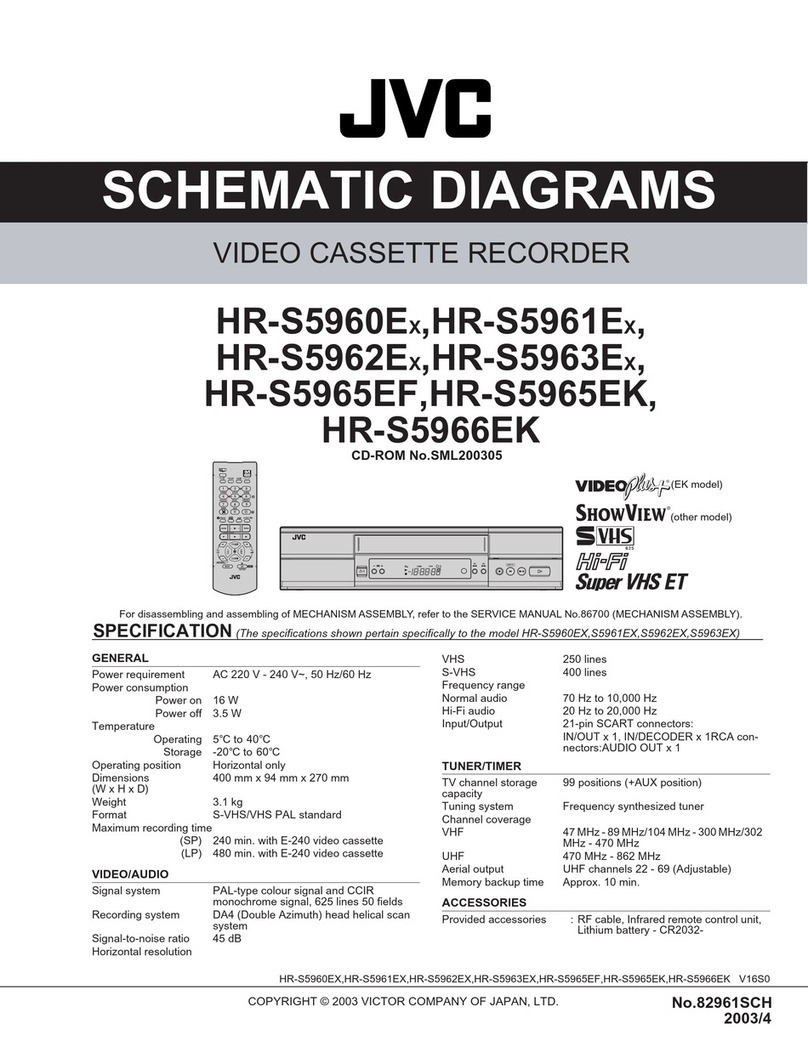

HR-S9700EK HR-S9700EU

VIDEO SYSTEM PAL/NTSC PB ON PAL TV PAL/MESECAM (MANUAL)/NTSC PB ON PAL TV

TUNER (BROADCASTING STANDARD)

1

B/G, D/K

TUNER (STEREO DECODER) NICAM NICAM/A2

TUNER (RF OUT SYSTEM)

1G, K

DISPLAY (LANG.) ENGLISH 14LANGUAGE

TIMER (VCR PLUS+) VIDEO PLUS+ DELUXE SHOW VIEW DELUXE

TIMER (VPS) NOT USED USED

The following table lists the differing points between Models (HR-S9700EK AND HR-S9700EU) in this series.