2.产品参数

Product parameters

操作方式:触摸屏、 脚踏开关

Operation mode: touchscreen, foot switch

工作模式:自动、半自动、自动选定

Working mode: automatic,semi-automatic, automatic selection

电源:AC210V~AC240V

Power supply: AC210V ~ AC240V

气压:≥2P

The pressure is not less than 2P

缠绕长度:∞

Winding length: ∞

缠绕组合线径:5MM-50MM

Winding assembly line diameter: 5MM-50MM

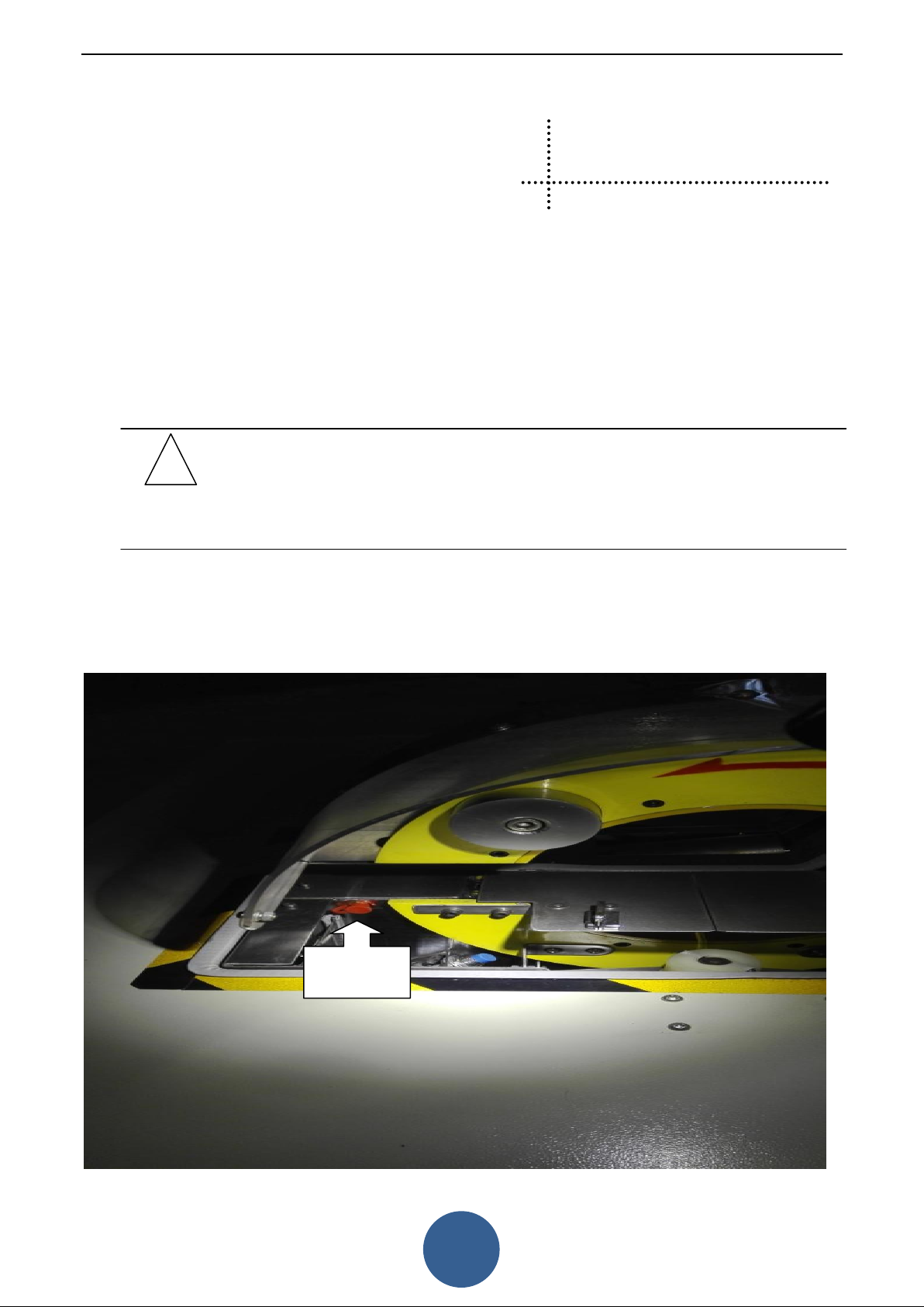

胶带规格:内¢38MM、外≤¢140MM、宽≤19MM(如有其它胶带尺寸,可按要求定制胶带

固定架)

Adhesive tape specification: inside diameter 38MM, outside small and equal to diameter 140MM,

width is less than or equal to 19MM (if there are other tape size, can be customized according to the

requirements of the adhesive tape holder)

胶带种类:PVC/绒布/布基等

Tape type: PVC/ cloth / cloth

工作温度:0-45°

Working temperature: 0-45°

工作湿度:10-90%RH(无冷凝)

Working humidity: 10-90%RH(no condensation)

冷却方式:自然风

Cooling mode: natural wind

缠绕最高频率:12R/S

Winding maximum frequency: 12R/S

运行参数:10P

Operating parameters: 10P