2-7 Operation Instruction for Installation

1) Prior to installation, please check whether the battery is normal.

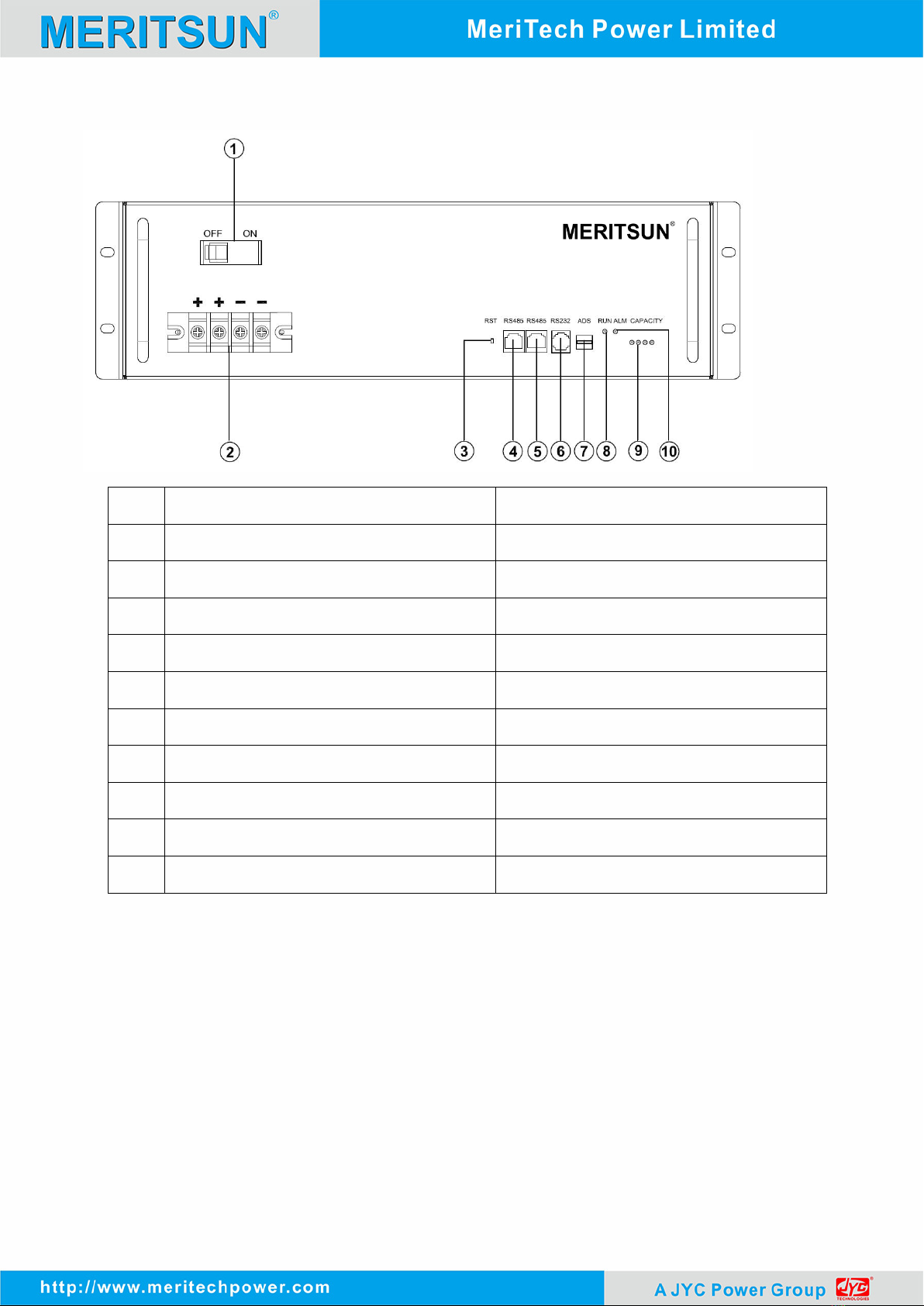

Press the reset key RST on the front panel for 3S for startup. During startup, 4 capacity indicator lights on the

front panel, ALM alarm indicator light (red) and RUN running indicator light lights up. Check whether all indicator

lights light up normally; then the ALM alarm indicator light goes out, the RUN running indicator light lights up and

the capacity indicator light lights up according to the capacity.

If the ALM alarm indicator light flashes after startup, it means that the battery has an alarm. The newly installed

battery seldom has alarm. The common alarm is the battery undervoltage alarm (which is resulted from non-use of

the battery for a long time). Such case may be removed after the battery is charged for 30min; if the alarm may not be

removed, please press the reset key RST for 10S, until all LEDs light up for reset, execute the battery reset operation

and confirm whether the alarm is removed. If the alarm is removed, the battery may be used normally. Otherwise the

battery shall be reworked.

2) For the battery which is normal after detection, please press the reset key RST for 3S to execute the battery

ON/OFF operation.

Instructions of

manual

operation of

the reset key

RST

Startup In the OFF state of BMS, press the key for 3S for

startup;

Shutdow

n

In the non-standby state of BMS, press the key for

3S for shutdown;

Reset In the non-standby state of BMS, press the key for

10S, until all LEDs light up for reset.

Instructions: “Shutdown” and “standby” and “startup” and “activation” in Chinese have the same meaning;

3) Installation of the lithium battery, wiring and startup.

Make the battery pack in a standby state, install it in the battery cabinet one by one, the anode and cathode of the

battery pack are connected respectively, which are connected to the switching mode power supply or UPS (Please

note that the switching mode power supply and UPS shall be disconnected from the AC). Press the reset key RST of

one of battery packs for 3S for startup. Such startup battery may activate other batteries which are connected in

parallel (or press the reset key RST of each battery pack for 3S successively) and the whole battery pack with high

capacity enters the working state. Later, apply AC to the power supply equipment such as switching mode power

supply and UPS to make the whole standby system run.

The specification of the connecting line is selected according to the load current, with the common

specifications of the connecting line as follows: