i

Volume:

Specific power:

Compressed air index:

612,371

6.20

15.51

Status

Messages

Monitoring

Energy & costs

Control

SAM 4.0 Logic

Time control

Initial Start-up

Configuration

Contact

Energy & costs – Diagram

SIGMA AIR MANAGER 4.0 4 Automatic 7.19 bar

Maintenance

1.1 On load € 9,415.20

1.2 Idle € 84.74

Energy costs € 9,499.94

1 Energy costs € 9,499.94

2 Amortisation € 6,000.00

3 Maintenance costs € 1,600.00

4

5

6

7

Total costs € 17,099.94

m³

kW/(m³/min)

€/1000m³

01.01.2014

Start:

00:00:00 31.12.2014

End:

23:59:00 Refresh

56%

35%

9%

99,1%

0,9%

Months ( M)

Interval

10000

8000

6000

4000

2000

kW

ACCESSMODE

Energy & costs – Period comparison

2000

0

Powerconsumption / kWh

Idle

0.00 0.00 0.00 0.00 80.93 10.39

Onload 0.00 0.00 0.00 0.00 9871.60 1247.58

Total 0.00 0.00 0.00 0.00 9952.53 1257.97

Volume/ m³ 0.00 0.00 0.00 0.00 101348.12 10713.20

Specificpower / kW(m³/min) 0.00 0.00 0.00 0.00 5.89 7.05

M 1/2015 M2/2015 M3/2015 M 4/2015 M5/2015 M 6/2015

i

Status

Messages

Monitoring

Energy & costs

Time control

Initial Start-up

Configuration

Contact

SIGMA AIR MANAGER 4.0 4

Manual 6.45 bar

Control

Observation

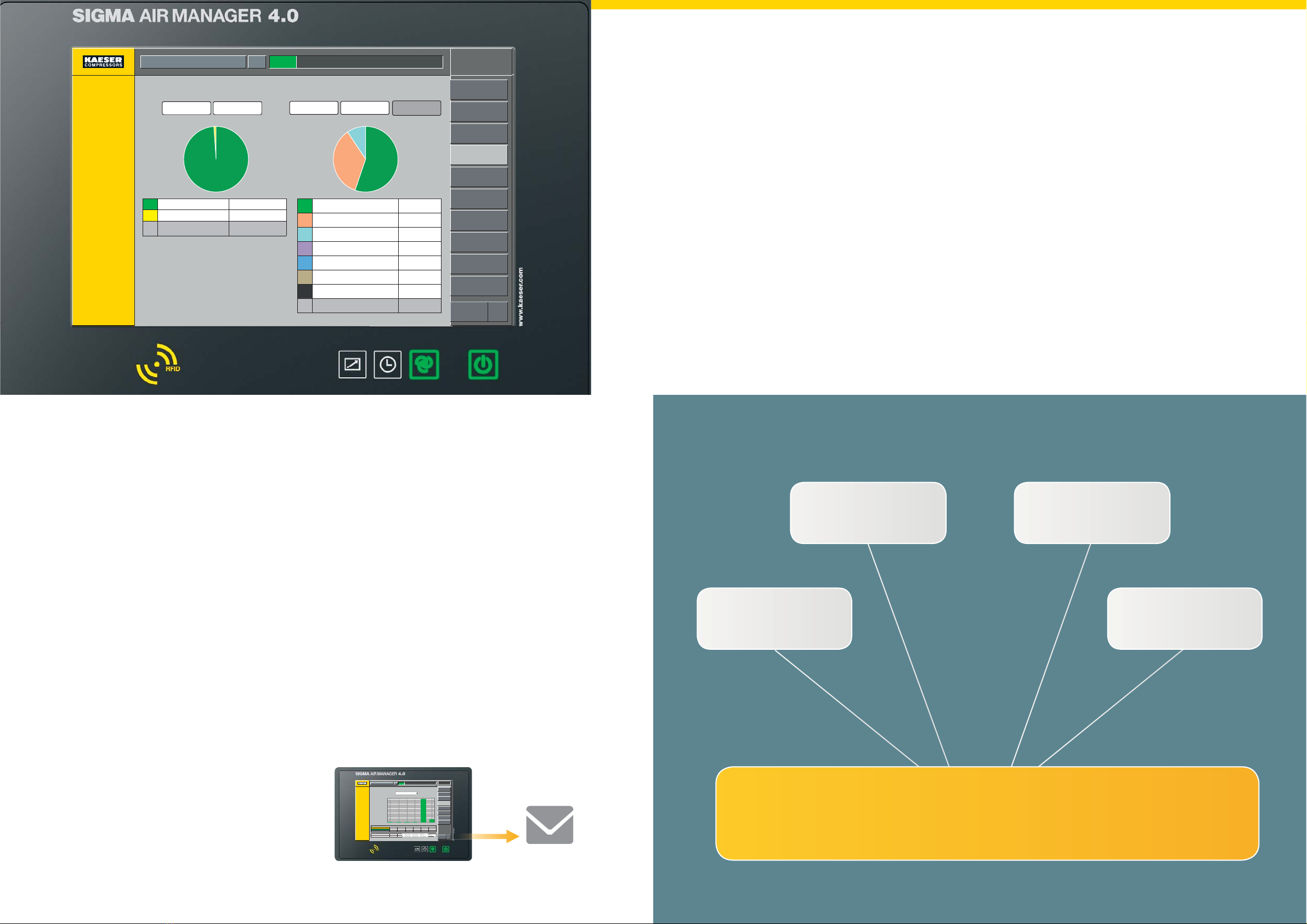

Easy data transfer to your

e-mail address

@

How the SIGMA AIR MANAGER 4.0

works for you:

To reduce both the environmental impacts and costs for

your business, the DIN EN ISO 50001 standard sets out

how businesses should systematically and continuously

improve their energy efficiency and rewards them ac-

cordingly through tax incentives and renewable energy

surcharge rebates.

The SIGMA AIR MANAGER 4.0 helps you create the

associated certification reports effectively and quickly:

it provides secure storage of your compressed air station’s

operating data and offers detailed analysis and energy

balances.

The following information is provided:

• Performance figures for the compressed air system or

individual components for energy management certifica-

tion in accordance with DIN EN ISO 50001

• Compressor load data, air delivery, performance, specific

power requirement

• Total costs

• Graphical display of cost overview (with the possibility

for manual value input, e.g. for maintenance and repair

costs)

• Operating data from the long-term memory for measuring

signals (over an elapsed period of up to one year)

• Energy cost settings

• Compressed air performance figures up to 6 years

The data can also be exported. The cost centre report can

be called up at any time via KAESER CONNECT with a

network-compatible end device. Furthermore, a period-

ical report can be forwarded to a user-definable e-mail

address.

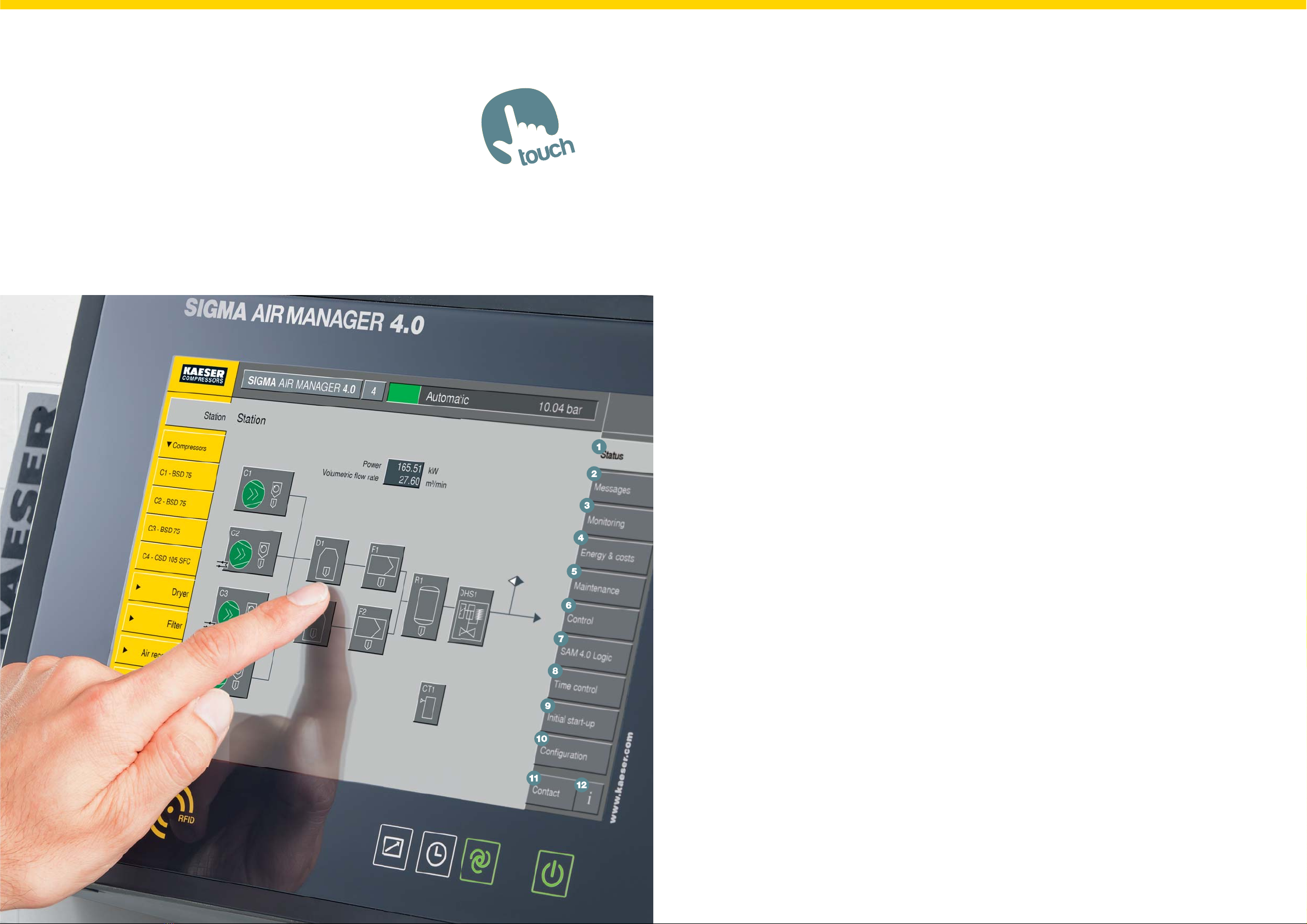

SIGMA AIR MANAGER 4.0. Logic allows customised

functions to be individually programmed via the KAESER

“Engineering Base” planning tool.

Therefore, using logic functions, it is possible to make

inlet, circulating and exhaust air louvres operate according

to temperature, for example. This powerful feature essen-

tially makes any additional PLC or logic control redundant.

This integration not only makes operation simpler, but

also provides a significant cost advantage compared to

the usual combination of a conventional controller with an

additional programmable logic controller (PLC).

If you would you like to find out more about SIGMA AIR

MANAGER 4.0. Logic simply contact your KAESER rep-

resentative regarding this optional service.

Integrated programmable control for individual

programmable functions.

SIGMA AIR MANAGER 4.0 Logic

On-demand energy reports – in the blink of an eye

Energy management certification as per DIN EN ISO 50001

As a leading compressed air systems provider, it goes without saying that KAESER provides unrivalled service and expertise

when it comes to energy efficiency. The SIGMA AIR MANAGER 4.0 is a comprehensive solution that allows you to store and

analyse all relevant, energy-related data from your compressed air supply, and then create specific reports for your certifica-

tion – all in the blink of an eye.

Summer/winter operation

of refrigeration/desiccant

dryers

Dryer changeover switch

Control of

inlet, circulating and exhaust air

louvres

Ambient temperature control

SIGMA AIR MANAGER 4.0 Logic

.

.

.

.

.

.

n

1110