Page

The night sensor used to work but doesn't now - what's gone wrong?

Light levels change with the seasons. Changing light bulbs or curtains can also have an effect.

Ideally your night sensor should be adjusted twice a year for lighter or darker months. See our

video guide for adjusting the night sensor. You, your landlord, agent or council can do this, or we

can attend for our standard call out fee.

How does a humidity sensor work?

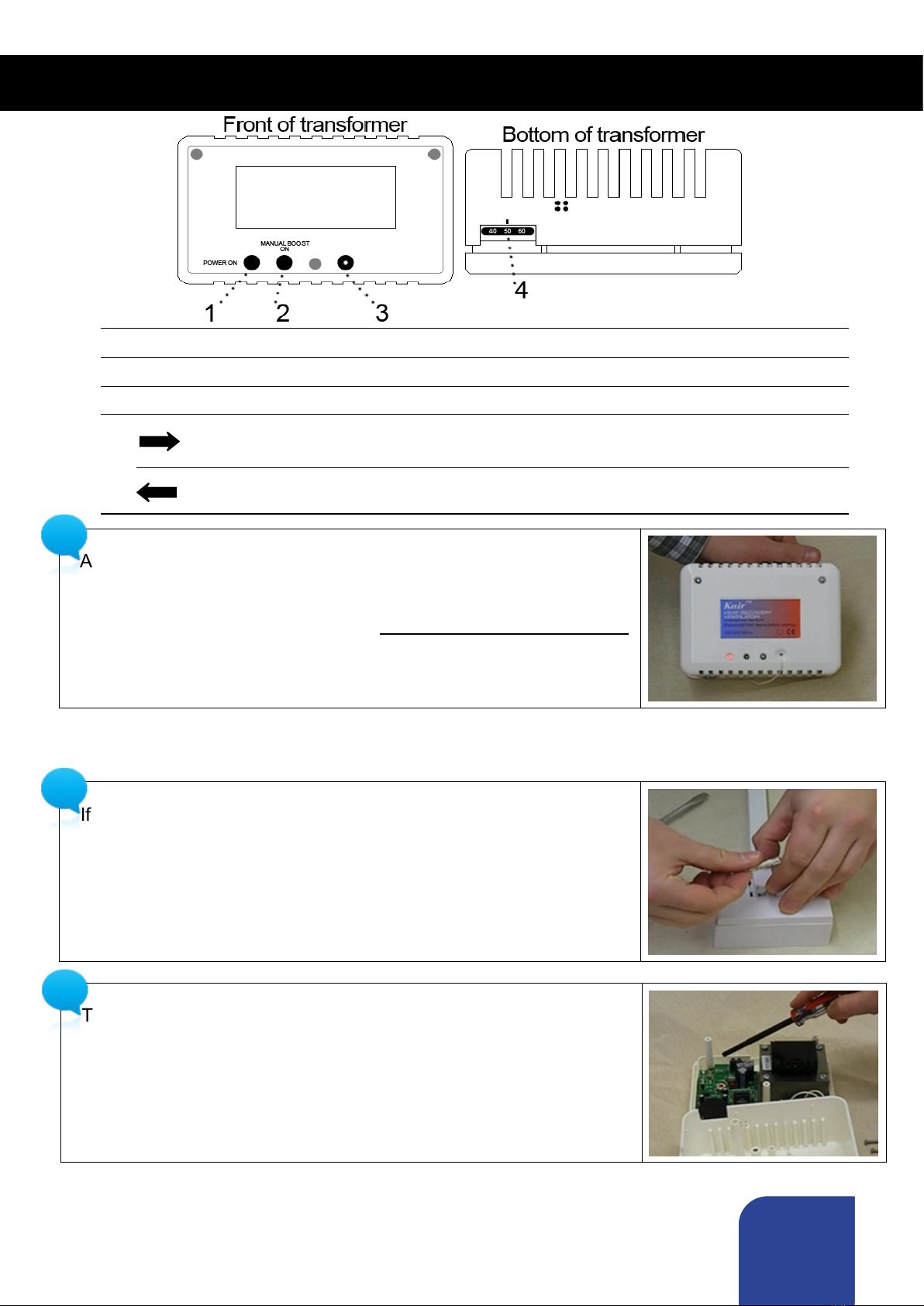

A humidity sensor measures the moisture content of the air. If the level rises beyond the set

threshold, the humidity sensor switches to boost. The threshold is adjusted using the dial on the

bottom edge of the transformer. The unit should be set at 50% as standard for ideal humidity

levels.

What are the filters for?

Filters clean the air coming into the building to keep it free of dirt, smoke particles etc. Our units

also filter the extracted air to protect and prolong the life of the heat exchanger, keeping it clean

to keep it functioning efficiently. Pollen filters are also available, with a denser, finer mesh, to

prevent allergens entering through the fan.

The unit is blowing in cold air!

This could mean the filters are clogged or blocked, which means less warmth is passed through

the heat exchanger. What colour are the filters? If grey or black, they need cleaning or replacing.

- Check the outside cowl is still attached to prevent cross-contamination.

- Is your heating on? If the room is cool, the fan cannot recover much, if any, heat. The unit only

recovers heat, it does not generate it.

- The heat exchange efficiency is less when the unit is on boost.

Moving air can feel cooler. Blow on your hand slowly, then quickly. The quicker air will feel cooler.

The unit won't come off boost!

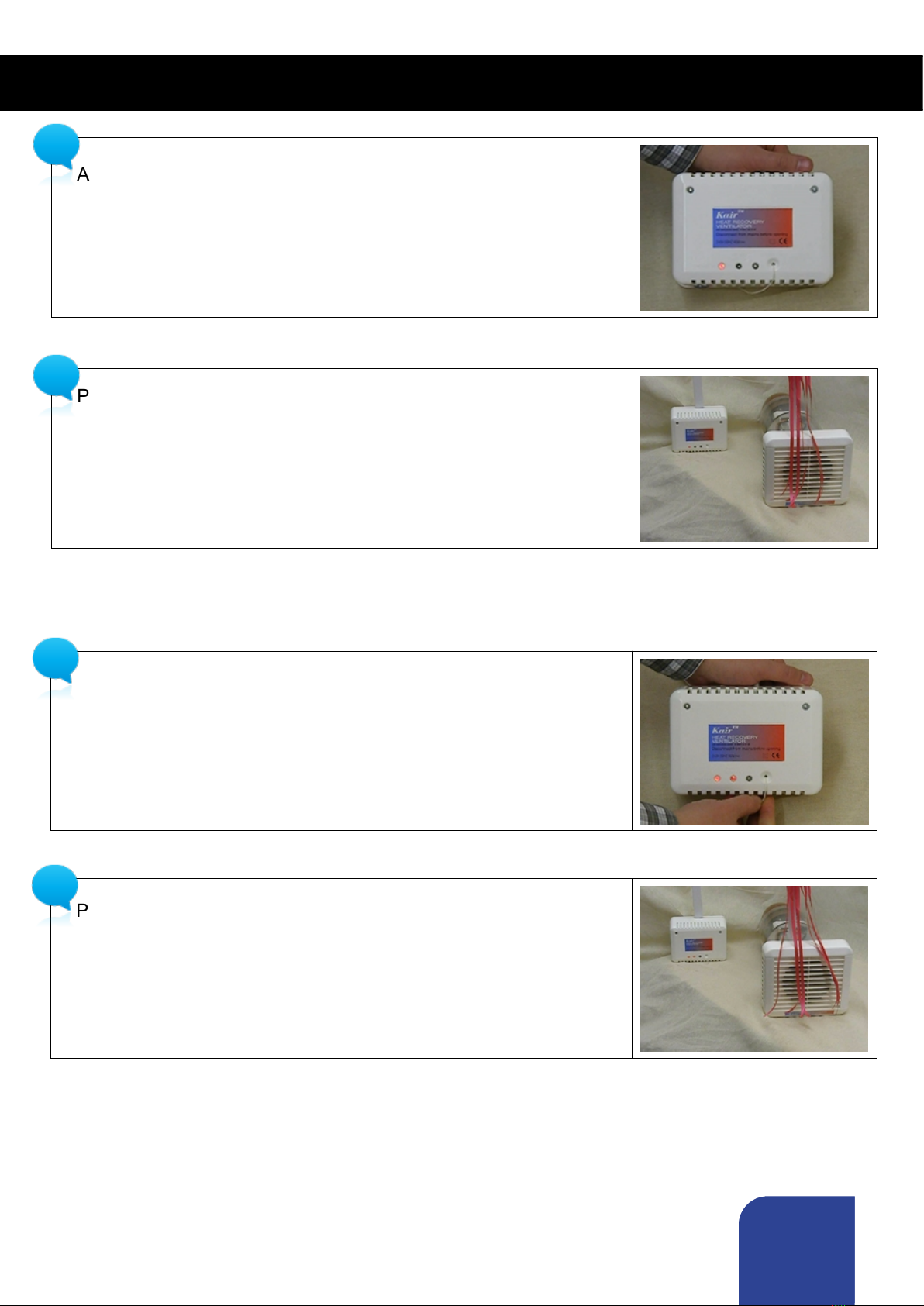

Are two lights on? If yes, can you pull the pullcord? If nothing happens, the pullcord may be

snagged. Isolate the mains, remove the transformer housing and make sure the pullcord is not

tangled or snagged.

The unit won't come on to boost!

The humidity sensor may be damaged, or the white rheostat may have been adjusted by

mistake. This needs to be re-calibrated using another humidity meter.

Can I switch off the unit?

This unit is designed to run constantly providing background ventilation and should be left on at

all times.

Other Frequently Asked Questions

The unit comes onto boost at night time.

The night sensor is improperly set. See page 4