CATⅢ

300V

CATⅠ

600V

LOW CU R R E N T DC CL AM P M E T ER

4000mA

40A / 200A

S K-7 8 3 0

OFF

0ADJ

DIFF

1sec<

( )

DH

MAX 200A

CATⅢ

300V

CATⅠ

600V

LOW CUR R EN T D C CL AM P M E TE R

4000mA

40A/ 200A

SK -78 3 0

OFF

0

ADJ

DIFF

1sec<

( )

DH

MAX200A

CATⅢ

300V

CATⅠ

600V

LOW CU R RENT DC CLA M P M ETER

4000mA

40A/ 200A

SK-7 8 3 0

OFF

0

ADJ

DIFF

1sec<

( )

DH

MAX200A

3. SAFETY PRECAUTIONS

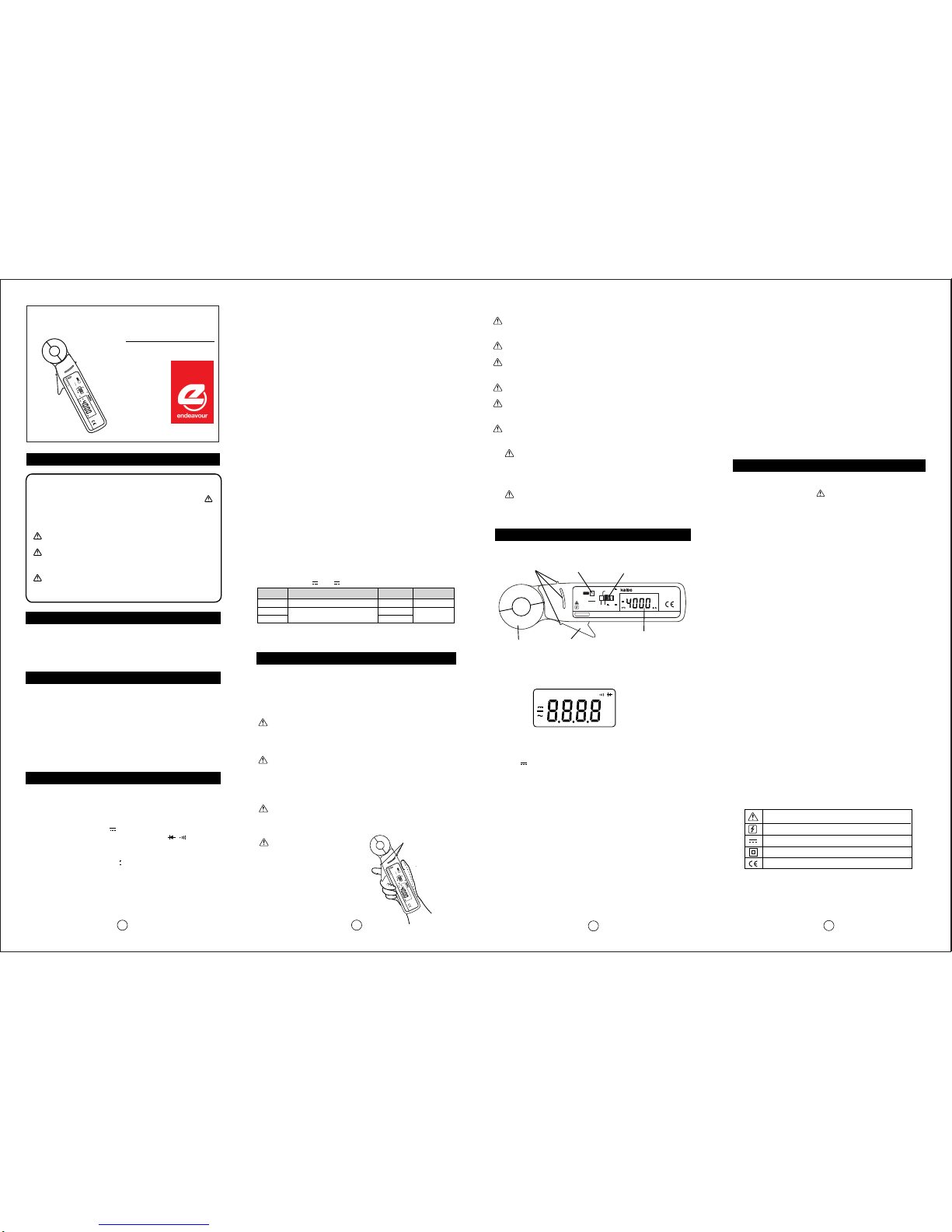

4. NAME ILLUSTRATION

(23℃±5℃、<80%RH in non-condensing)

1. DC CURRENT ( mA, A)

WARNING 1. Checks of Clamp Meter Body

WARNING 2. Warning for High Power Line Measurements

WARNING 3. Maximum Input Observance

234

2-2. MEASUREMENT SPECIFICATIONS

3-1. WARNINGS

3-2. GENERAL WARNINGS AND CAUTIONS

Children and the persons who do not have enough

knowledge about electric measurements must not

use this instrument.

Do not measure the electricity naked or barefooted to

protect yourself from electrical shock hazard.

Do not polish the case or attempt to clean it with any

cleansing fluid like gasoline or benzine. If necessary,

use silicon oil or antistatic fluid.

Avoid the clamp meter from hard mechanical shock or

vibration, high temperature and strong magnetic field.

Remove the batteries when the clamp meter is out of

use for a long time. The exhausted batteries might

leak electrolyte and corrode the inside.

Do not measure AC high-frequency current. Clamp

head becomes heated and could damage the

instrument.

Do not make a measurement under large

temperature difference. In case that the clamp meter

moved into high temperature place from low

temperature, turn the power on and leave it for a

while to get it used to the surrounding temperature.

When measuring, open clamp head 15mm or

wider and close it softly. Detach fingers from trigger

after clamping a conductor.

WARNING 1.

WARNING 2.

CAUTION 1.

CAUTION 2.

CAUTION 3.

CAUTION 4.

FOR SAFETY MEASUREMENTS!!

INTRODUCTION

1. UNPACKING AND INSPECTIONS

1

To prevent an electrical shock hazard to the operator and/or

damage to the instrument, read this instruction manual carefully

before using the Clamp Meter. WARNINGS with the symbol

on the Clamp Meter and this instruction manual are highly

important.

Important Symbols

The symbol listed in IEC 61010-1 and ISO 3864 means

"Caution (refer to instruction manual)".

WARNING : The symbol in this manual advises the user

of an electrical shock hazard that could result in serious

injury or even death.

CAUTION : The symbol in this manual advises the user of

an electrical shock hazard that could cause injury or

material damages.

Thank you for purchasing ET7830 LOW CURRENT DC

CLAMP METER". To obtain the maximum performance of

this instrument, read this Instruction Manual carefully, and take

safe measurements.

Inspect the instrument and accessories for transport damage.

If there is any damage or missing items, ask your local dealer

for replacement.

Confirm that the following items are contained in the package.

1. Digital Clamp Meter

2. Carrying Case (1011)

3. Batteries (1.5V R6P)

4. Instruction Manual

8. DISPLAY HOLD : Hold indicating values by DH Key

9. ZERO-ADJUSTMENT (DIFFERENCE MEASUREMENT) :

Adjust LCD into 0±1 digit and/or start Difference Measurement by

0 ADJ (DIFF) Key.

10. AUTO POWER OFF : Power turns off automatically after a lapse

of following minutes.

a. 4000mA range : Approx. 5 minutes

b. 40A/200A range : Approx. 10 minutes

11. OVERLOAD PROTECTION : 400A AC/DC rms for 1 minute

(50/60Hz)

12. DIELECTRIC STRENGTH : 3.54kV AC, 50Hz sine wave, for 1

minute (between iron core and case)

13. OPERATABLE TEMPERATURE & HUMIDITY :

0℃to 40℃, 80%RH or lower in non-condensing.

14. STORAGE TEMPERATURE & HUMIDITY :

-20℃to 60℃, 70%RH or lower in non-condensing.

15. TEMPERATURE COEFFICIENT : Accuracy in 23℃±5℃×0.1/℃

16. SAFETY LEVEL : CE Marking approved (IEC-61010-1, CAT Ⅲ

300V, CATⅠ600V and EMC Test passed.)

17. POWER SUPPLY : 1.5V R6P (AA) batteries ×2

18. POWER CONSUMPTION : 26mA max.

19. CONTINUOUS OPERATING TIME : Approx. 60 hours (Alkaline

cell), Approx. 30 hours (Manganese cell) (in 40A/200A range, 0A

input)

20. CONDUCTOR DIAMETER : φ20mm max.

21. DIMENSIONS & WEIGHT : 203(H)×61(W)×30(D)mm,

Approx. 230g (including batteries)

22. ACCESSORIES : 1011 Carrying Case, 1.5V R6P (AA) batteries

×2, Instruction Manual

2. SPECIFICATIONS

, −, 〜, mA, A, mV, V, Ω, kΩ, MΩ,

Hz, kHz, %, nF, μF, , , DH, DIFF,

PH, MAX, MIN, APO, BAT, AUTO, LPF

and decimal point.

Σ

2-1. GENERAL SPECIFICATIONS

1. DISPLAY (LCD)

a. Numerical Display : 4000 count, Maximum reading 4050,

12mm high

b. Units and Symbols :

2. OPERATING PRINCIPLE : ⊿conversion

3. SAMPLING RATE : 64 times / second(Display : 1time/second)

4. RANGE SELECTION : Manual-ranging(4000mA),

Auto-ranging(40A/200A)

5. POLARITY : Auto-Polarity ("ー" indication in minus)

6. OVERLOAD INDICATION : "OL" indication blinks

7. BATTERY WARNING : "BAT" indication at approx. 2.3V or less

Do not measure any current that might exceed the specified

maximum input values.

WARNING 4. Safety Line

Do not put your fingers over the

safety line while current

measurement. (Refer to fig.1)

Correct knowledge of electric measurements is essential to avoid

unexpected danger such as operator's injury or damage to the

instrument. Read carefully and observe the following precautions for

safe measurement.

Before measurement, confirm the body of this instrument has no

cracks or any other damages. Dust, grease and moisture must be

removed.

High Power Line (High Energy Circuits) such as Distribution

Transformers, Bus Bars and Large Motors are very dangerous. For

safety of high power line measurement, do not touch the live line and

keep enough distance.

LOW CURRENT

DC CLAMP METER

ET7830

INSTRUCTION MANUAL

Range

4000mA

40.00A

200.0A

Resolution

1mA

10mA

100mA

Max.Input

Current

Overload Protection : 400A AC/DC rms (for 1 minute) (50/60Hz)

Range Selection : Manual-ranging / Auto-ranging

Accuracy

±1.5%rdg±5dgt (from 5mA)

200A DC

4000mA DC

LCD

DH Key

Trigger

0 ADJ (DIFF) Key

Clamp Head

FUNCTION Switch

Safety Line

Turns the power on and selects measurement functions. After

measurement, turn it to "OFF".

4-4. FUNCTION Switch

Opens and closes the clamp head. When measurement, open

clamp head 15mm or wider and close it softly. Detach fingers from

trigger after clamping a conductor.

4-7. Trigger

Holds indicating measurement values. ("DH" lights up)

To cancel it : Press DH key again.

4-5. DH Key : Display Hold

Zero-Adjustment : Press this key for 1 second or more when

zero-point adjustment is necessary. LCD indications are adjusted

into 0±1 digit.

Difference Measurement : Press this key for 1 second or more

while measurement. Convert a measurement value into zero and

indicate the relative values.

To cancel it : Press 0 ADJ (DIFF) Key for 1 second or more.

4-6. 0 ADJ (DIFF) Key :

Clamp on a single conductor to measure DC current.

NOTE : Unable to measure if several conductors are clamped.

AUTO

BAT

−

APO

DH

DIFF

mA, A

Lights up in auto-ranging measurement

Low battery warning

Lights up at minus

Lights up in DC current measurement

Auto power off indication

Lights up in display hold function

Lights up in zero-adjustment and difference

measurement

Lights up in current measurement

:

:

:

:

:

:

:

:

4-1. LCD

4-2. Clamp Head

The line to protect yourself against electrical shock hazard. Do

not put your fingers over this line while measuring current.

4-3. Safety Line

AUTO DH DIFF MAX MIN

PH

BAT LPF

APO

kMΩ

%mVA

Hz F

μ

n

1pce.

1pce.

2pcs.

1pce.

(0 to 100A)±1.5%rdg±5dgt

(101 to 200A)±3.0%rdg±5dgt

(

fig.2

fig.1

Before using this instrument, install 2 of 1.5V R6P (AA) batteries

refering to 「6-1. BATTERY REPLACEMENT」. Replace them in

the same way when "BAT" lights up on LCD.

5-1. PREPARATION FOR USE

1. INSTRUCTION MANUAL

Read INSTRUCTION MANUAL carefully to understand the

specification and functions correctly. 「3. SAFETY

PRECAUTIONS」is highly important for safe measurement.

2. BATTERY

"OL" lights up on LCD if measurement value exceeds maximum

indicatable value of each measurement range (4050 digits or 2050

digits).

3. OVERLOAD INDICATION

5. MEASUREMENT PROCEDURES

Power turns off automatically after approx. 5 minutes (4000mA

range) or after approx. 10 minutes (40A/200A range) of last

FUNCTION Switch operation to conserve battery life. (Small-

current-consumption remains. After measurement, be sure to set

FUNCTION Switch to "OFF".)

To cancel it (40A/200A range only) : Hold down DH Key and set

FUNCTION Switch from "OFF" to "40A/200A". Auto power off is

canceled and "APO" disappears from LCD.

NOTE : Auto power off cannot be canceled in 4000mA range.

4. AUTO POWER OFF

Safety Line

1 :

2 :

Caution (refer to instruction manual.)

Caution for current-applied dangerous conductor

Direct Current (DC)

Double Insulation

CE Marking Conformity

The following symbol marks shown on the instrument and

instruction manual are listed in IEC 61010-1 and ISO 3864.

Automatic zero-adjustment function to adjust LCD indications into

0±1 digit when powered on.

NOTE :

NOTE :

5. POWER-ON INITIALIZE

6. SYMBOL MARK

INITIALIZE does not work properly if some inputs are

applied.

Do not touch trigger when turning on the power.

INITIALIZE does not work correctly if any pressure is

applied to trigger or clamp head is opened.

*Accuracy after zero adjustment