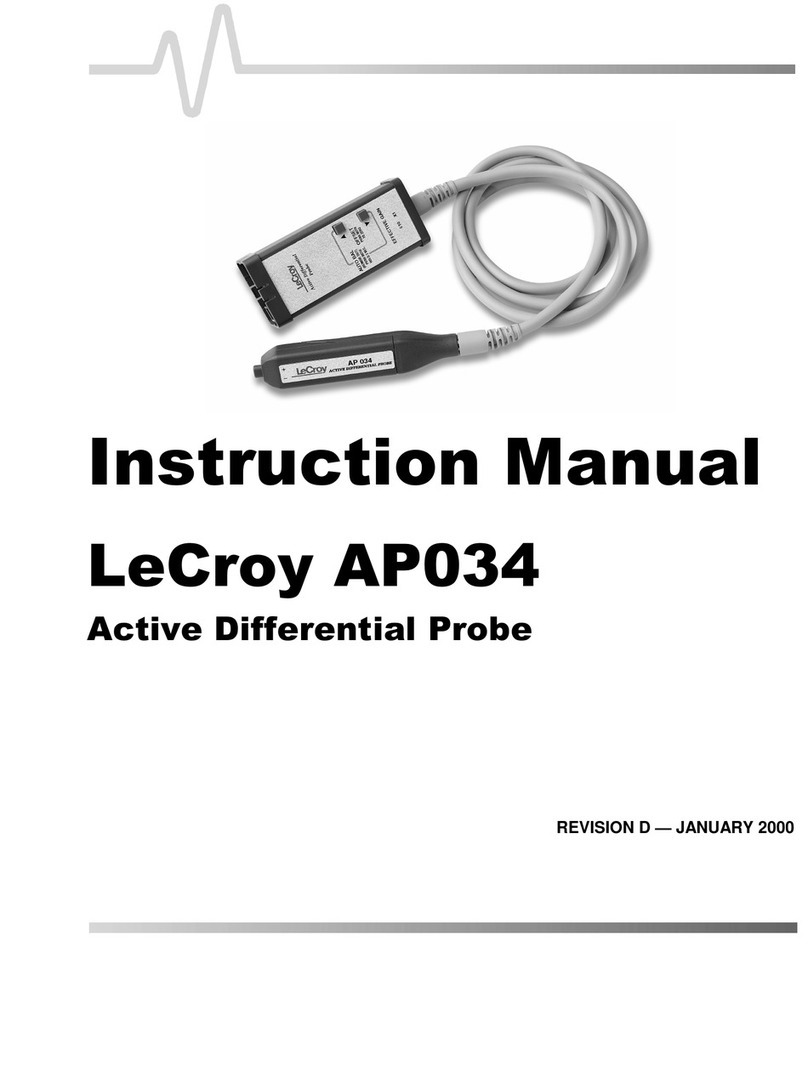

DXC100A Probe

A Word about Differential Amplifiers and Probes

When using a differential amplifier it is very important to understand the role probes play in the overall

measurement system performance. Probes not only make attachment to the circuit under test more

convenient, 10X and 100X attenuating probes also extend the common mode range of the differential amplifier.

For example, the DA1855A amplifier has a common mode range of ± 15.5 volts when the internal attenuators

are set to ÷1 and 155 volts when set to ÷10. The addition of a probe with an attenuation factor of ten extends

the common mode range to 1550 volts or the rating of the probe, whichever is less.

However there is a trade-off in that the Common Mode Rejection Ration (CMRR) capability of even highly

matched differential probe pairs seldom matches that of the amplifier. In order to preserve the amplifier’s

performance at the probe tips, it is important to use probes designed for differential performance. Attempting

to use normal 10X or 100X attenuating oscilloscope probes, even high quality probes, results in very poor CMRR

performance. Nominally matching X1 probes, however, provide excellent common mode rejection and are

recommended.

When making differential measurements, probe compensation is just as important as it is for single-ended

measurements. While probe compensation is important, how well the probes are matched is essential. Most

probes depend on the accuracy of the oscilloscope’s 1 MΩ input resistor to determine the accuracy of the

probe’s attenuation factor. Two probes with a 1% accuracy specification can yield a CMRR as low as 50 to 1 at

DC while the amplifier CMRR may be higher than 100,000 to 1. At high frequencies, the CMRR is worse.

A differential probe pair must allow for matching at DC as well as over their useful frequency range. Changing

the compensation of a differentially matched probe set without following the proper compensation procedure

can result in a significant decrease in the CMRR capability of any differential probe pair.

It is considered good practice to compensate a probe pair for a given amplifier and then keep the probe pair

and amplifier together as a system. Similarly, it is important that once a probe is compensated for a given

amplifier, the respective probe always is used on the same input (meaning, one probe always used on the

+INPUT and the other always on the –INPUT).

The DXC100A Differential Probe Pair

The DXC100A is a high performance matched passive differential probe pair designed for use with LeCroy

differential amplifiers. The probe pair consists of two well-matched individual probes sharing a common

compensation box allowing the attenuation factor on both probes to be simultaneously switched between 10X

and 100X. When used with the LeCroy Model DA1855A Differential Amplifier, the probe’s attenuation factor is

automatically incorporated into the effective gain display and the decimal properly located in the Precision

Voltage Generator (PVG) display. Although primarily designed for use with LeCroy amplifiers, the DXC100A

Differential Probe pair can be used with any oscilloscope or plug-in unit with an input impedance of 1 MΩ/15-

26pF and one inch (25.4 mm) spacing between connectors.

Probe Grounding

The DXC100A Probe Pair is supplied with accessories allowing for three probe ground connection methods.

In most cases, when the common mode portion of the signal consists mainly of low frequencies (1 MHz and

below), the probe ground leads should not be connected to the ground of the circuit under test. Instead, they

should be connected to each other to minimize the effects of ground loop currents. The signal corruption caused

by not having the probes connected to the ground of the circuit under test is common to both inputs and

rejected by the differential amplifier.

However, when working in an environment with high RF ambient noise, it is best to connect the probe ground

leads to a good RF ground near the point where the signal is being measured.