ElektroPhysik MiniTest 7200 FH Technical Document

Technical Manual /Operating Instructions

MiniTest 7200 FH / MiniTest 7400 FH

Thickness Gauges

Contents

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

2

Contents

1. INTRODUCTION..........................................................................................................................5

2. FIRST STEPS.................................................................................................................................6

2.1 INSERT BATTERIES AND CONNECT SENSOR .................................................................................6

2.2 SWITCH ON AND TAKE READINGS..............................................................................................7

2.2.1 Setting language..................................................................................................................7

3. DESCRIPTION OF THE MEASURING SYSTEM...................................................................9

3.1 BASIC UNIT .................................................................................................................................9

3.1.1 General Remarks.................................................................................................................9

3.1.2 Operating keys ....................................................................................................................9

3.1.3 Sockets and interfaces.......................................................................................................10

3.1.4 Power supply.....................................................................................................................10

3.1.4.1 Batteries and storage batteries......................................................................................10

3.1.4.2 Power supply unit...........................................................................................................11

3.2 SENSORS FH 4 AND FH 10........................................................................................................11

3.2.1 General Remarks...............................................................................................................11

3.2.2 Sensor Models...................................................................................................................11

3.2.3 Sensor Stand......................................................................................................................12

4. THE USER MENU.........................................................................................................................13

4.1 G

ENERAL

R

EMARKS

....................................................................................................................13

4.2 S

WITCH

-ON / S

TART

S

CREEN

......................................................................................................13

4.3 MEASURE SCREEN /STATISTICS SCREENS ..................................................................................13

4.3.1 Measure Mode – Numerical Screen..................................................................................13

4.3.2 Measure Mode –Graphics Screen with MiniTest 7400 FH ..............................................14

4.3.3 Statistics Screens...............................................................................................................14

4.4 USER MENU ..............................................................................................................................15

4.4.1 USER PREFERENCES...............................................................................................................15

4.4.2 NUMERICAL ENTRIES.............................................................................................................16

4.4.3 ALPHANUMERICAL ENTRIES (ON MINITEST 7400 FH)...........................................................16

5. MEASURE MODE......................................................................................................................17

5.1 IMPORTANT NOTES ON THICKNESS MEASUREMENT..................................................................17

5.1.1 Limitations to magneto-static thickness measurement......................................................17

5.2 BATCH CONFIGURATION / NECESSARY SETTINGS.....................................................................17

5.2.1 Batch .................................................................................................................................17

5.2.2 Target Ball Size.................................................................................................................18

5.2.3 Data Logging Mode..........................................................................................................18

5.3 PREPARING MEASUREMENT......................................................................................................18

5.3.1 Calibration........................................................................................................................18

5.3.2 Measurement without Sensor Stand..................................................................................19

5.3.3 Using the Sensor Stand.....................................................................................................19

5.4 TAKE READINGS .......................................................................................................................19

5.4.1 Measurement without Sensor Stand..................................................................................19

5.4.2 Using the sensor stand......................................................................................................20

5.4.3 Delete Readings ................................................................................................................20

5.5 STORING READINGS INTO STATISTICS MEMORY .......................................................................20

5.5.1 Data Logging Mode..........................................................................................................20

5.5.2 Manual Data Storage........................................................................................................21

Contents

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

3

5.5.3 Automatic Data Storage (Auto).........................................................................................21

5.5.4 Storing Minimum Reading................................................................................................21

5.5.5 Storing Maximum Reading................................................................................................21

5.6.1 Correct Sensor Position....................................................................................................22

5.6.2. Incorrect Readings through tilting of the Sensor.............................................................22

5.6.3 Incorrect readings through Blocked Target Ball..............................................................23

5.6.4 Air gap...............................................................................................................................23

5.6.5 Measuring material with ferruginous particles................................................................23

6. CALIBRATION...........................................................................................................................24

6.1 GENERAL REMARKS ON CALIBRATION .....................................................................................24

6.2 CALIBRATION METHODS............................................................................................................25

6.3 HOW TO CALIBRATE..................................................................................................................26

6.3.1 Factory Calibration ..........................................................................................................26

6.3.2 Zero only...........................................................................................................................26

6.3.3 Multi-point calibration (Zero + 1 to 4 point(s) )..............................................................27

6.4. DELETE CALIBRATION POINT....................................................................................................28

6.5 CALIBRATION ERROR SOURCES ................................................................................................29

7. DATA STORAGE........................................................................................................................30

7.1 BATCHES...................................................................................................................................30

7.1.1 General..............................................................................................................................30

7.1.2 Batch Data ........................................................................................................................30

7.2 DATABASE OF THE MINITEST 7400 FH.....................................................................................31

7.2.1 General Remarks...............................................................................................................31

7.2.2 Tree structure....................................................................................................................31

7.2.3 Create a Directory............................................................................................................31

7.2.4 Create a New Batch ..........................................................................................................32

7.2.5 Select a Batch for Measurement .......................................................................................32

7.2.6 Delete a Batch / a Directory .............................................................................................33

7.2.7 Rename a Batch / Rename a Directory.............................................................................33

8. STATISTICS................................................................................................................................34

8.1 STATISTICAL PARAMETERS.......................................................................................................34

8.1.1 Upper and lower specifications limits (USL and LSL).....................................................34

8.1.2 Set Point (Differential Mode)............................................................................................35

8.2 READINGS .................................................................................................................................35

8.2.1 View Readings...................................................................................................................35

8.2.2 Delete Single Readings .....................................................................................................35

8.2.3 Delete all Readings...........................................................................................................36

8.3 NUMERICAL STATISTICS ...........................................................................................................36

8.4 HISTOGRAM ON MINITEST 7400 FH .........................................................................................37

8.5 TREND DIAGRAM ON MINITEST 7400 FH.................................................................................37

9. DATA OUTPUT / DATA TRANSFER......................................................................................38

9.1 D

ATA

P

RINT

-O

UT

........................................................................................................................38

9.1.1 Screen Shot........................................................................................................................39

9.1.2 Print-out a Batch...............................................................................................................39

9.2 TRANSFER DATA TO A PC.........................................................................................................40

10. MAIN MENU .............................................................................................................................41

10.1 DATABASE ..............................................................................................................................41

Contents

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

4

10.2 STATISTICS..............................................................................................................................41

10.3 CALIBRATION..........................................................................................................................41

10.4 ACTIVE BATCH .......................................................................................................................41

10.4.1 Batch Properties .............................................................................................................41

10.4.2 Readings..........................................................................................................................42

10.4.3 Configuration..................................................................................................................42

10.4.4 Calibration......................................................................................................................42

10.5 S

ETUP

.......................................................................................................................................43

10.5.1 General Remarks.............................................................................................................43

10.5.2 Display............................................................................................................................43

10.5.3 Date and Time.................................................................................................................43

10.5.4 Data Outputs...................................................................................................................44

10.5.5 User Preferences.............................................................................................................45

10.5.6 Gauge Specifications.......................................................................................................45

11. SPECIAL FUNCTIONS............................................................................................................46

11.1 INITIALIZING ...........................................................................................................................46

11.2 S

PECIAL FUNCTIONS

..................................................................................................................47

12. QUICK REFERENCE ..............................................................................................................48

13. CARE AND MAINTENANCE.................................................................................................49

13.1 CARE.......................................................................................................................................49

13.1.1 Using NiMH storage batteries........................................................................................49

13.2 M

AINTENANCE

.....................................................................................................................49

14. TECHNICAL SPECIFICATION.............................................................................................50

14.1 G

AUGE AND

S

ENSOR

S

PECIFICATION

..........................................................................................50

14.2 DELIVERY SCHEDULE .............................................................................................................52

14.2.1 Thickness gauge MiniTest 7200 FH / 7400 FH..............................................................52

14.2.2 Sensors............................................................................................................................52

14.3 ACCESSORIES..........................................................................................................................53

15. APPENDIX.................................................................................................................................56

15.1 T

ROUBLESHOOTING

...................................................................................................................56

15.2 D

ETECTION OF

E

RROR SOURCES

(INF

FLAG

)...............................................................................59

15.3 STATISTICAL TERMS ...............................................................................................................60

15.4 SAFETY NOTES........................................................................................................................62

15.5 D

ECLARATION OF

C

ONFORMITY

.................................................................................................64

15.6 A

FTER

S

ALES

S

ERVICE

..............................................................................................................65

INDEX...............................................................................................................................................66

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

5

1. Introduction

Designed for non-destructive thickness measurement, the portable MiniTest 7200 / 7400 FH

measuring systems are suitable for in the field or laboratory use. Working on the magneto-static

principle, the gauges enable quick and easy measurement on non-ferromagnetic materials.

The measuring system consists of a handy sensor, which is connected via a cable to the base and

display unit for visualization and processing of readings. For measurement, specially treated target

balls made of a ferromagnetic material are used as a reference. For measurement, a target ball is

placed on the material to be measured so that the material thickness between target ball and

sensor will be measured. The measuring system comes with sensor stand (available as an option)

to add additional comfort of handling during measurement.

For documentation a portable data printer is available. The measuring system may also be

connected to a PC for data communication.

For taking readings, the sensor is placed on the surface of the measuring object, the target ball is

placed on the opposite side of sample. The sensor is placed on the opposite side of sample.

Equipped with a strong permanent magnet, the sensor attracts the target ball and holds it exactly

over its sensor tip. When moving the sensor, the target follows accordingly. The presence of the

target ball will change the magnetic field near the sensor tip. The magnetic field changes according

to the distance between target ball and sensor tip. The change of magnetic field increases with the

distance between target ball and sensor tip getting smaller and can be taken as a reference for the

material thickness of the sample to be measured. The sensor incorporates a Hall element to

capture the change of magnetic field and to translate it into thickness.

For measuring hollow parts, a target ball is placed into the interior of sample and the sensor is

placed on the opposite side in order to attract the target ball exactly over the sensor tip. For taking

readings, the sensor is moved over the surface of sample. For measuring sheets, the sensor is

placed on the surface of sheet and the target ball is placed near the sensor on the opposite side of

sheet. The target ball will automatically center on the correct measuring position and the

measuring processes can be started.

For measuring large-sized parts, the sensor can be guided manually over the sample to be

measured. For measuring small parts, it is recommended to use the sensor stand supplied with the

sensor.

Suitable for use in industrial production areas, the measuring systems MiniTest 7200 / 7400 FH

measure hollow parts, containers and sheet material of all kinds such as bottles, cans, injections

moldings, car bodies, glass, SMC components etc made of non-magnetic (non-ferrite) materials.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

6

2. First Steps

This section refers to persons to use the gauge for the first time. This section explains the main

features of the gauge and how to take readings.

2.1 Insert Batteries and connect Sensor

a) Take gauge and batteries from the carrying case.

b) Push the battery compartment lid at the gauge bottom in arrow direction (as shown below)

c) Insert batteries into the battery compartment. Respect polarities (as shown below).

d) Close lid.

b) c)

e) Take requested sensor (FH4 or FH10) form the carrying case. Plug sensor into the socket on

top of the base unit (as shown below). Make sure the nib of plug is correctly inserted into the

guide way of socket. The red marking at the probe plug must be positioned correctly to the red

marking at the sensor plug.

f) Fully engage the sensor plug into the sensor socket to the stop.

Sensor Socket

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

7

2.2 Switch ON and Take Readings

2.2.1 Setting language

This setting can be made at initial use or as requested at any time (see section 11.1)

Press the red ON/OFF button on the left side of gauge and ESC simultaneously to switch on and to

go to initialization menu.

1. A banner appears with a language option.

User arrow keys ↑↓ to go to your requested language option.

Press OK to confirm or ESC to abort.

2. On display appears “Total Reset”. A Total Reset restores factory settings. To abort Total

Reset, press Function key “No” (section 11.1)

a) Start Screen appears showing company logo, gauge version

and sensor type that is currently connected (see illustr. on the

left.

b) After approx. 2 seconds, the gauge switches automatically into

measure mode and is ready to take readings. The Measure

Screen will appear without any reading being shown.

c) At initial switch-on the gauge is in “Direct Mode“ (see section

7.1.1). For this mode, the factory calibration is preset (for more

detailed information on “Calibration” topics please refer to section

6). The Status Line provides information on the active calibration

method and the active batch (MiniTest 7400 FH) Please check

whether the target ball size as adjusted matches your application

(for more details on target ball size pleaser refer to section 5.2.2

“Target ball size”).

Flashing antenna symbol if sensor is

connected

Selected calibration mode, here:

Zero calibration

Target ball diameter, hiere: 4.0 mm.

Active batch, here: Pet bottle

(only with Minitest 7400 FH)

Status line

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

8

d) The factory calibration is for quick and easy measurement when larger measuring errors are

acceptable. For other calibration methods please refer to section 6.2.

e) For measurement, please use the sensor stand supplied with the gauge. Place the measuring

object on the sensor. Place the target ball on the opposite side. For measuring hollow parts,

place the ball inside the sample. Equipped with a strong permanent magnet, the sensor attracts

the target ball and holds it exactly over its sensor tip. Hold the measuring object in rectangular

position to the sensor and move it smoothly over the sensor. Press OK to store the reading into

memory. Press Function key “Statistics” to view readings and the numerical statistics.

For measuring large-sized sheeting material or large hollow parts, place the senor on the

surface of sample. The target ball is placed on the opposite side near the sensor. Keep the

sensor in rectangular position to the surface and move it across the surface of sample.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

9

3. Description of the measuring system

3.1 Basic unit

3.1.1 General Remarks

3.1.2 Operating keys

Use the ON/OFF button to switch the gauge ON or OFF. If you press ON/OFF button and ESC

simultaneously, the initializing procedure will be performed (for more details please refer to section

11.1).

The Function keys may assume different functions according to the menu being active. Their

current properties are displayed in the line upper to the Function keys.

The command and navigation key block may also assume different functions:

-

Press OK to confirm settings, store values or select menu items.

-

Press ESC to abort actions or to quit submenus.

-

Use ARROW keys to navigate through the menu or change settings.

-

If the alphanumerical block has been activated, OK and ESC keys also assume navigation

functions.

The Function keys and the command and navigation key block may be backlit on request. This

adds additional comfort in poor light conditions (for more details please refer to section 10.5.2)

Function keys

ON/OFF button

Command and

navigation key

block

Graphics display

160 x 160 Dots

Large backlit display for easy reading of

measuring values, statistical data, histogram and

trend diagram.

Robust scratch resistant plastics housing.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

10

Press the “Help” Function key for calling the context-oriented on-line “Help“.

3.1.3 Sockets and interfaces

The basic unit features a sensor socket for connecting the FH 4 or the FH 10 sensor. The multi-

purpose socket is used for connecting the mains unit, the foot switch, the alarm device or the

RS232 interface cable.

3.1.4 Power supply

3.1.4.1 Batteries and storage batteries

Both models, MiniTest 7400 FH and MiniTest 7200 FH, are powered by a set of four alkaline-

manganese cells, 1.5V, AA LR6 size (Batteries included in the standard supply schedule.).

As an alternative, both models may be operated on rechargeable NiMH (type AA-HR6) storage

batteries or via a power supply unit (available as an option). Please use only products as

recommended by ElektroPhysik (See section 14.3, Accessories).

If you wish to use the storage batteries, they must be recharge using the external charger unit

(available as an option). Please also refer to section 13.1 “Care and maintenance” for more details.

Note:

• Remove batteries or storage batteries from the instrument if you are not going to use it for a

longer period of time.

• The battery symbol on display indicates the battery state.

• For field use, replacement batteries should be made available.

• Erratic readings due to low battery voltage do not occur because the gauge switches off or

does not switch on if the battery is too low.

Multi-purpose socket Sensor socket

IR Interface

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

11

• Used or defective batteries or storage batteries may contain hazardous substances and

must be disposed according to the legal provisions of your country.

3.1.4.2 Power supply unit

For mains operation, the power supply unit must be used. If operated via the power supply unit,

batteries should be inserted to supply the internal time clock, otherwise, after approx. 1 minute, the

settings of the real-time clock will go lost as soon as supply from the mains is cut.

The power supply unit comes with two different adapter plug versions (Euro and US plug). If the

power supply unit comes with an adapter plug connected that does not match your socket, simply

change the adapter plug accordingly.

Simply remove the adapter from the power supply unit and fix the other one as required.

Note:

The adapter has not been designed for frequent change.

3.2 Sensors FH 4 and FH 10

3.2.1 General Remarks

In this new SIDSP (Sensor integrated digital signal processing) procedure, all necessary

measuring signals are created and completely processed in the sensor itself. Only the completely

processed digital readings are transferred to the base unit for display, statistical evaluation and

data storage. Unlike the commonly used analog procedures, the new SIDSP procedure excludes

any error influences on the measuring data during transfer over the probe cable. The result is a

measuring accuracy and constancy of readings that has been unmatched so far. The complete

sensor technique is integrated into a robust stainless-steel housing.

3.2.2 Sensor Models

Two sensor models are available:

-

FH 4 sensor to cover the 0 …4 mm range

-

FH 10 sensor to cover the 0…10 mm range.

Both sensors feature a wear-resistant sensor tip most suitable also for hard materials such as

glass, for instance.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

12

3.2.3 Sensor Stand

Both sensor types come with a spring-loaded V-grooved sensor stand. The use of the sensor stand

ensures increased reproducibility of readings by adding stability of the sensor during measurement

so that even small parts can be measured without problems.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

13

4. The User Menu

4.1 General Remarks

4.2 Switch-ON / Start Screen

At switch on, the company logo, gauge version and type of sensor being connected appear on

display.

After approx. 2 seconds the gauge switches to the measure screen of the last batch that was

active before the gauge was switched off.

4.3 Measure screen /Statistics screens

Readings can be displayed numerically only or numerically combined with a diagram (only with

MiniTest 7400 FH)

4.3.1 Measure Mode – Numerical Screen

Target ball size and measuring unit

Power supply indicator

Time clock

Adjusted set point

Current reading

CALIBRATION MODE

Number of readings

The current

function key

proper-

ties

are indicated in the line above the

function keys.

Active batch (MiniTest 7400FH only)

Minimum reading

Maximum reading

Status line

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

14

4.3.2 Measure Mode –Graphics Screen with MiniTest 7400 FH

For setting the Real-Time Trend display option, select “Active Batch” form the Main Menu. Press

OK to confirm. Select “Configuration” from the Batch Menu and press OK to confirm. Use the arrow

keys to move to the “Graphics” option. ON or OFF is highlighted. Use arrow keys to make your

selection and press OK to confirm or the “ESC” navigation button to restore previous setting and to

go back to the previous menu level.

To take full advantage of the real-time trend it is necessary to tolerance limits (see also section

8.11 „Upper specification limits (USL) and lower specification limits (LSL)“.

4.3.3 Statistics Screens

,

Target ball size, measuring unit

DATA LOGGING MODE

Power supply indicator

Time clock

Reading

NAME OF ACTIVE BATCH

⇓

LOWER LIMIT

⇑

UPPER LIMIT

CALIBRATION METHOD

MAX = MAXIMUM READING

MINIMUM READING

N = NUMBER OF READINGS

REAL

-

TIME TREND

Set point

The current

function key

proper-

ties

are indicated in the line above the

function keys.

STATUS LINE

The current

function key

proper-

ties

are indicated in the line above the

function keys.

Power supply indicator

Time clock

Process capability,

cp and cpk

Selected calibration mode

Active batch

(MiniTest 7400 FH only)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

15

4.4 User Menu

The numerous MiniTest FH 7400 / 7200 features can be accessed via the different menus that are

divided into submenus.

Press the Function key “Main menu“ in order to get access to the main menu.

Select an item from the Main Menu (e.g. Database) and press OK to confirm. You will go to a

submenu. Use the arrow keys to select the requested item and press OK to confirm.

To go back to the previous menu level press ESC.

According selected submenu you can

-

View settings (e.g. Gauge specs = Gauge specifications in the Setup Menu)

-

Select preset parameters (e.g. 100% brightness from the Display Menu)

-

Make numerical or alphanumerical entries (e.g. Enter a directory name in the database / new

directory option).

4.4.1 User Preferences

Use the arrow keys to select your requested menu item, e.g. Language.

Press OK to confirm. The current selection will be highlighted. Use the

arrows to select the requested parameter (e.g. English) and press OK to

confirm. To undo your selection, press ESC and you will return to the

previous menu level.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

16

4.4.2 Numerical Entries

As soon as the alphanumeric block is activated, ESC and OK will

assume navigation functions to the left or right. Choose your character

by placing the cursor over the requested character. After a certain period

of time, the entry will be accepted automatically without the need to

confirm. This period of time can be specified under User Preferences in

the “Entry accepted” option. See also section 10.5.5 for further

reference. Complete your entry by pressing Function key “Ready” and

then confirm “Save changes?” by pressing OK.

4.4.3 Alphanumerical Entries (on MiniTest 7400 FH)

For alphanumerical entries you can use as many as 15 characters for

entering a name. ESC and OK assume navigation functions to the left or

right. Choose your character via the alphanumerical block. Your

selection will be automatically accepted after the previously specified

period of time. This period of time can be set under User Preferences in

the “Entry accepted” option. See also section 10.5.5 for further

reference. Complete your entry by pressing Function key “Ready”.

Complete your entry by pressing Function key “Ready” and then confirm

“Save changes?” by pressing OK.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

17

5. Measure Mode

5.1 Important Notes on Thickness Measurement

Make sure that the operator has been properly instructed regarding the use of thickness gauges

and has basic knowledge of the specific requirements for measurement of the application. The

operator should have basic knowledge of the following:

• Selection of a measuring device suitable for his application

• Fundamentals on the magneto-static measuring principle

• Influences on the magnetic fields through the surrounding field

• Influence of the surface properties of the material to be tested (roughness, build-up on the

surface)

• Statistical evaluation of measuring series

• Gravity influencing the reference ball

5.1.1 Limitations to magneto-static thickness measurement

The information obtained from thickness measurements according to the magneto-static principle

only refer to those parts of the test object that have been covered by the magnetic sensor. For that

reason, be careful to draw conclusion on other parts of the measuring object that have not been

covered by the sensor during measurement. In general, such conclusions are only admissible if

comprehensive experience and approved methods of statistical data acquisition are available.

5.2 Batch Configuration / Necessary Settings

Before taking readings, it is necessary to make a few settings in the Configuration menu. The

Configuration always refers to a certain measuring series (Batch).

5.2.1 Batch

-

You can continue to take readings in the active batch

-

You can create a new batch (only with MiniTest 7400 FH model)

-

You can choose an exiting batch from the database (please refer to section 7.2).

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

18

5.2.2 Target Ball Size

According to sensor type and the shape of measuring object, a

suitable target ball must be set. This can be made in the Configuration

menu, menu item “Target ball” (also refer to section 6 “Calibration”.

Use arrow keys to move to “Target Ball” size and press OK. Use arrow

keys to adjust the requested target ball size. Press OK to confirm your

setting or press ESC to undo your setting. If you undo, you will

automatically quit tar

get ball setting option and go back to the previous

menu level.

5.2.3 Data Logging Mode

In the data logging mode you can specify how you wish readings to be stored in memory. Several

modes are available:

-

manually or via footswitch (Current reading, MIN, MAX)

-

Automatic (Auto)

Note: For logging data into memory please always proceed as follows: Put the sensor into the

correct measuring position, press ESC. Then readings can be taken.

5.3 Preparing Measurement

Before measurement, the probe must be adapted to the ambient temperature. In case of high

variations in temperature, the target ball must be lifted from the probe tip at regular intervals (e.g.

every other minute). This is to compensate for frequency drift due to variations in temperature. It is

recommended to switch on the gauge for warming up around 2 to 3 minutes in order to ensure

maximum measuring accuracy.

5.3.1 Calibration

According to your setting of task, you may use different calibration methods. Measuring accuracy

depends on the selected calibration method. Please refer to section 6 for more details on this

issue.

There are three calibration methods available:

-

Factory

-

Zero only

-

Multi-point calibration (Zero + 1 to 4 Point(s)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

19

5.3.2 Measurement without Sensor Stand

For measuring large-sized parts, the sensor can be guided manually over the measuring sample.

For measuring thick samples (6 mm and thicker) make sure to keep the sensor in vertical position

to the sample. When holding the sensor in horizontal position, due to the influence of gravity on the

steel ball, the readings will be higher than the actual thickness.

5.3.3 Using the Sensor Stand

For measuring small parts, bottles or other cylindrical bodies the sensor stand (supplied with the

sensor) and a footswitch (available as an option) should be used.

Put the sensor into the stand and secure with the red sensor stand

retaining ring.

5.4 Take Readings

5.4.1 Measurement without Sensor Stand

For measurements on large-sized sheeting material or large hollow parts, place the sensor onto

the surface of the object to be measured. Place an appropriate target ball on the opposite side of

object near the sensor. The target ball will be attracted by the strong permanent magnet of sensor

and be positioned centrally just opposite of the sensor tip. Keep the sensor in right-angle position

to the object to be measured and scan continuously over the surface. For storing readings, please

refer to section 5.5.1.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

20

5.4.2 Using the sensor stand

If you are using the sensor stand, position the sample on the sensor tip and keep it in right-angle

position to the sensor. Place the appropriate target ball on the opposite side of object. Make sure

to keep the right-angle position while moving the object continuously over the sensor. For storing

readings, please refer to section 5.5.1.

When measuring small hollow parts such as bottles e.g., put the target ball inside the object and

place the object onto the v-grooved device of sensor stand. Turn the object until the target ball is

centered directly over the sensor tip. Then move the object continuously over the v-groove of

sensor stand. For storing readings, please refer to section 5.5.1.

5.4.3 Delete Readings

Please refer to section 8.2.2 “Delete Single Readings“.

5.5 Storing Readings into Statistics Memory

5.5.1 Data Logging Mode

During measurement, readings can be stored into memory manually or automatically. Data in

memory will be used for statistics.

The following storing options are available:

-

Storing the current reading manually or automatically

-

Storing the minimum reading (only manually)

-

Storing the maximum reading (only manually).

The Data logging mode can be specified in the “Configuration” submenu. Use arrow keys to select

the Data logging mode option and press OK to confirm. You can chose from the following setting

options:

-

Curr. reading (Current reading)

-

Auto

-

Max

-

Min

Make your selection and press OK to confirm. If you wish to undo your setting (before OK has

been pressed) press ESC and the gauge will return to the previous menu level.

This manual suits for next models

1

Table of contents

Other ElektroPhysik Measuring Instrument manuals

ElektroPhysik

ElektroPhysik SmarTest User manual

ElektroPhysik

ElektroPhysik MiniTest 700 Manual

ElektroPhysik

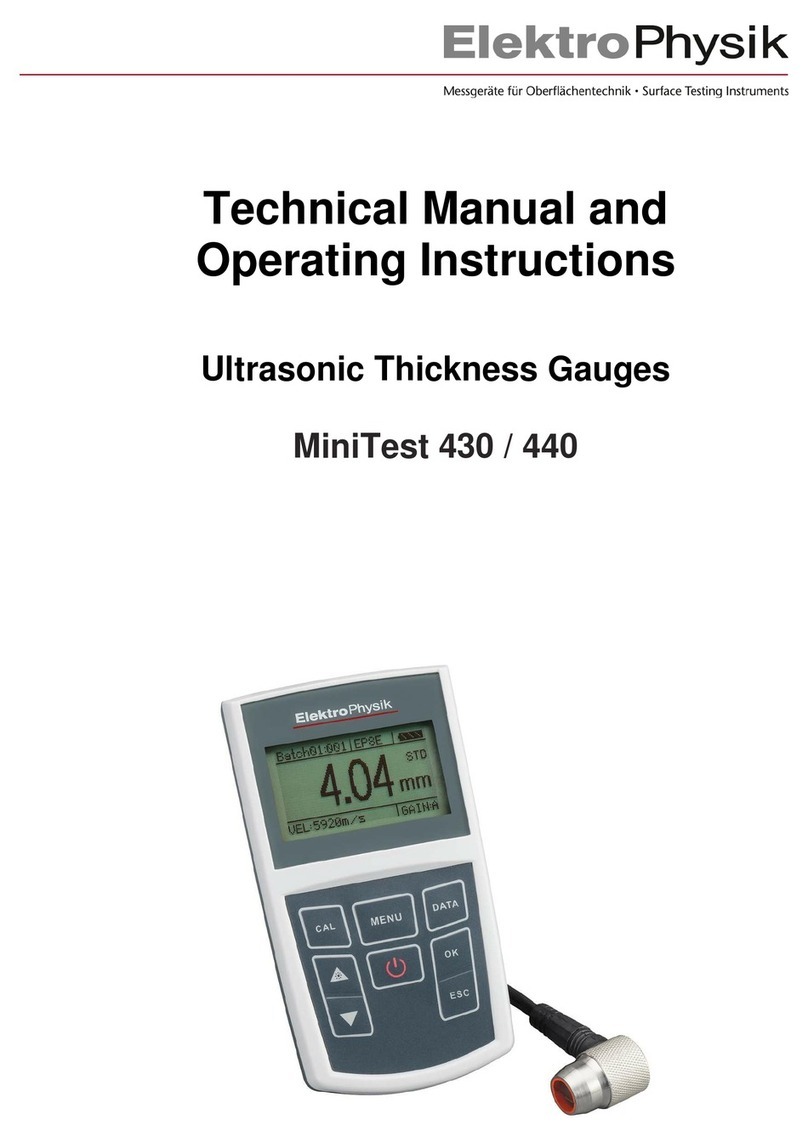

ElektroPhysik MiniTest 430 Use and care manual

ElektroPhysik

ElektroPhysik MiniTest 4500 User manual

ElektroPhysik

ElektroPhysik MiniTest 403 Use and care manual

ElektroPhysik

ElektroPhysik MiniTest 725 Technical Document

ElektroPhysik

ElektroPhysik QuintSonic 7 Technical Document

ElektroPhysik

ElektroPhysik MiniTest 440 Use and care manual

ElektroPhysik

ElektroPhysik MiniTest 430 Technical Document