4

2. Safety Information

Installation, assembly and maintenance work on electrical units should

only be performed by a qualified electrician in compliance with the VDE

guidelines. Wiring should comply with the applicable VDE regulations and

provisions laid down by the regional electricity providers. Non-compliance

with the regulations and operating instructions may result in the units

malfunctioning with consequential damage and danger to people. The

units may be incorrectly wired by the wires being swapped – danger

of fatal injury! Disconnect all parts of the system from the mains power

supply and prevent them from being reconnected before starting any

connection and maintenance work! The unit should only be connected to

fixed cabling.

Please read these instructions in full to guarantee a correct installation.

Please note the following safety-relevant information:

• Disconnect all parts of the system that are being worked on.

• Ensure that the system cannot be accidentally re-connected!

• Caution! Pipes, casings and fittings may become very hot depending on

the operating mode!

• Qualified personnel must have undergone training to provide them with

adequate knowledge of the following:

• Safety and accident prevention regulations

• Guidelines and recognised technical regulations, i.e. VDE (Association of

German Electricians) regulations

• DIN and EN standards

• Accident prevention regulations VBG, VBG4, VBG9a

• DIN VDE 0100, DIN VDE 0105

• EN 60730 (Part 1)

• Technical wiring regulations issued by the regional electricity providers

Modifications to the unit

Do not undertake any modifications, refurbishments or upgrades on the

Katherm NX unit without discussing these with the manufacturer as these

may impair the safety and operation of the unit. Do not carry out any

action on the unit that is not described in these instructions. On-site

systems and cabling must be suitable for connection to the intended

system!

The floor duct has openings provided for the installation of

a potential compensation line.

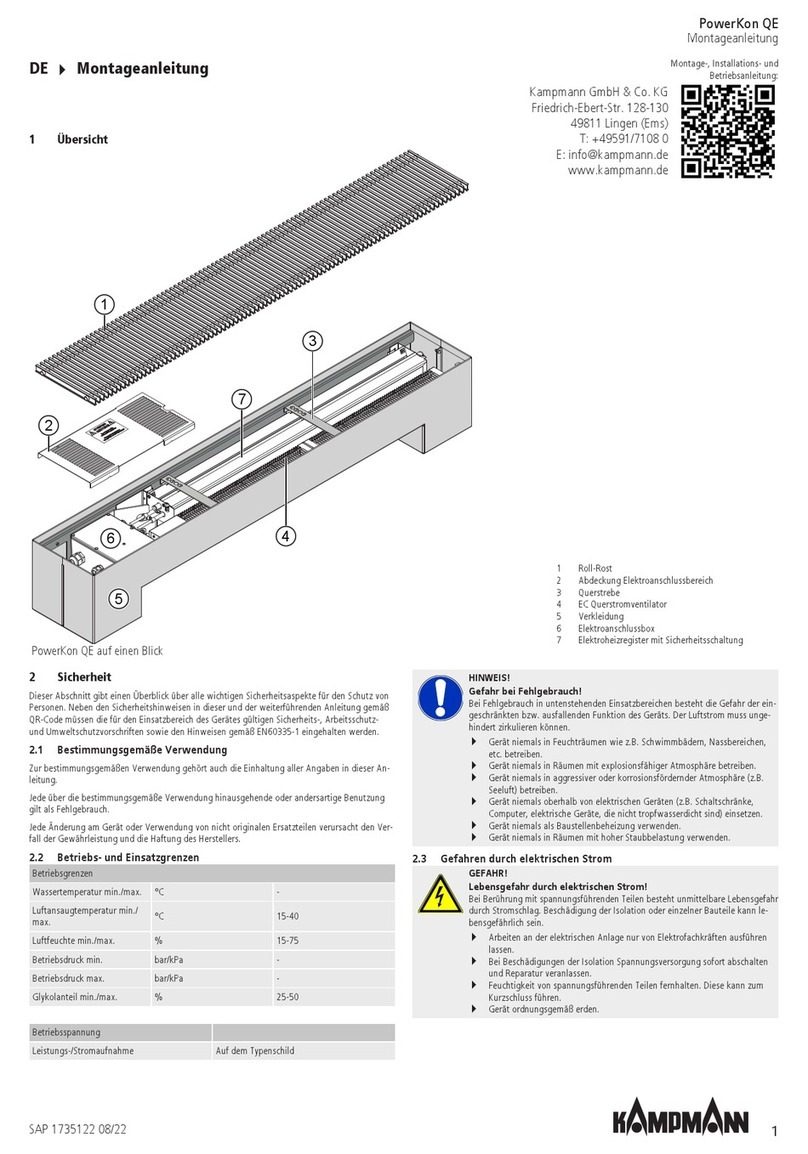

3. Models/Scope of Delivery

Floor ducts are delivered as standard with the following (see Fig. 2):

leight-adjustment feet, room-side, 1Rubber underlays for sound

absorption 2; screws and rawlplugs, provided on-site;

lraised floor mounting feet with sound absorption 3

3.45 Katherm X - atural Convection

Safety Information