3Kamstrup A/S • 55122070_A2_GB_07.2017

MULTICAL® 603

Contents

1 General information 4

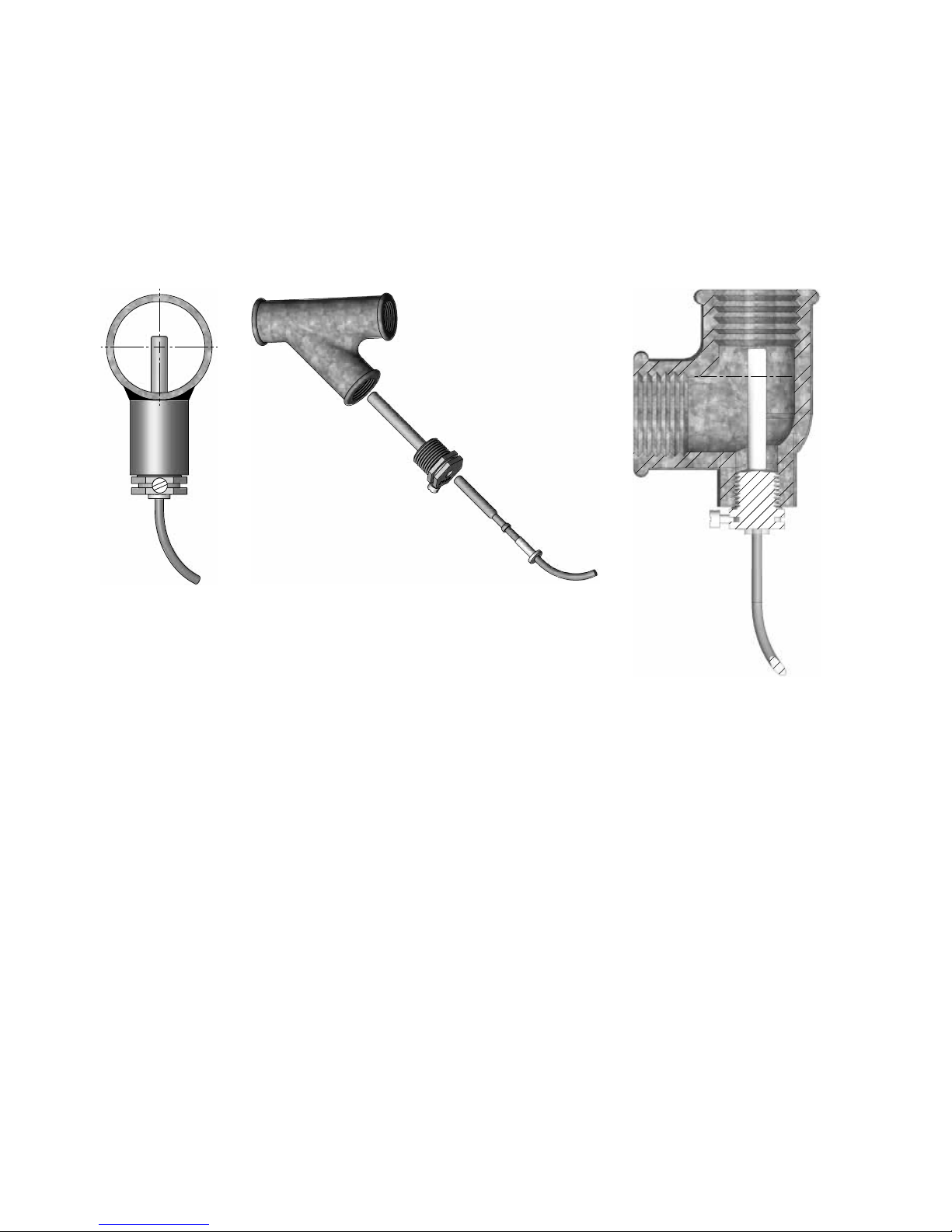

2 Mounting of temperature sensors 5

2.1 Short direct sensor (DS) 5

2.2 Pocket sensor (PL) 6

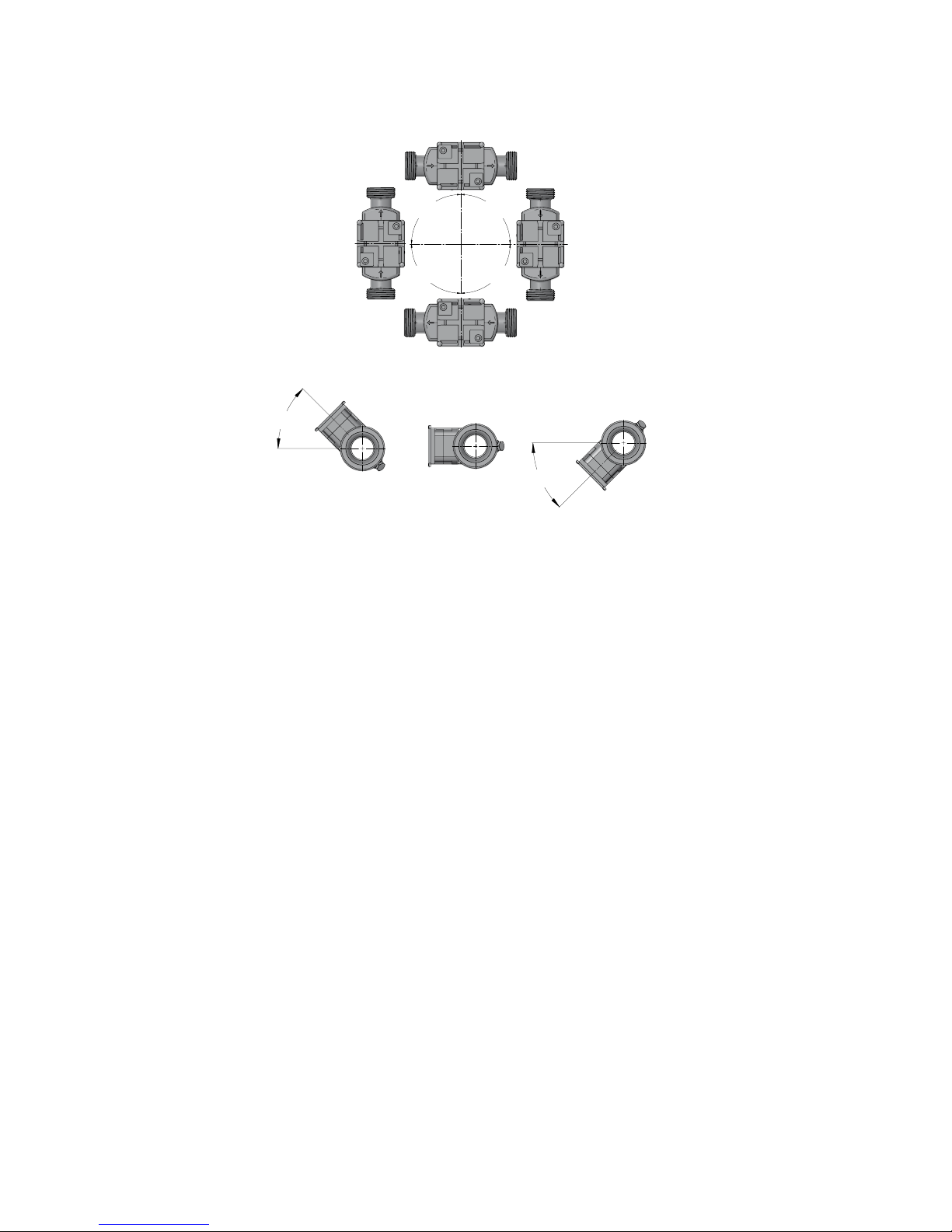

3 Mounting of flow sensor 7

3.1 Mounting of couplings and short direct sensor in flow sensor 7

3.3 Mounting of ULTRAFLOW® 54 ≥ DN150 8

3.2 Mounting of ULTRAFLOW® ≤ DN125 8

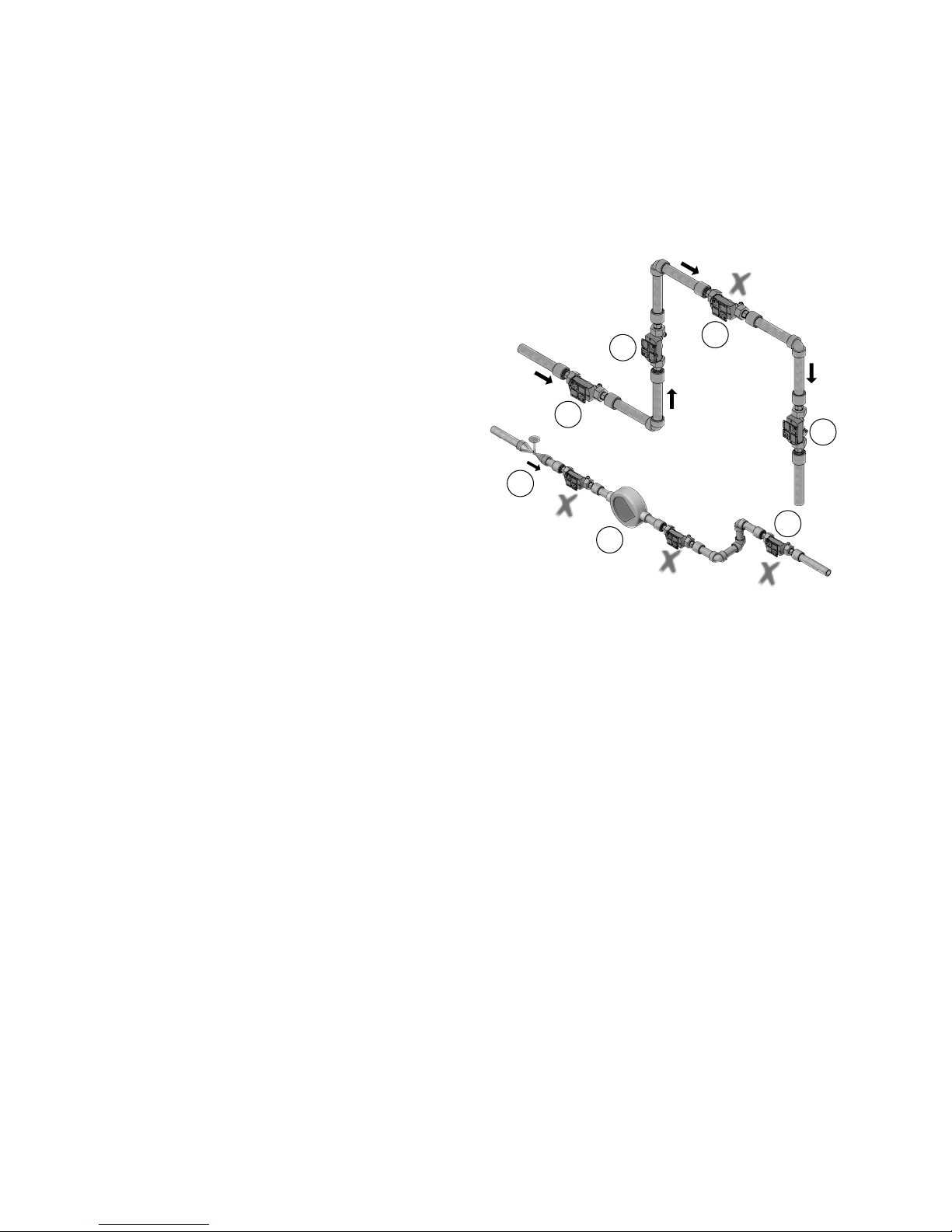

3.4 Flow sensor position 9

3.5 Installations with two ULTRAFLOW® sensors 10

4 Mounting the calculator 11

4.1 Compact mounting 11

4.2 Wall-mounting 11

5 Electrical connection 12

5.3 Cable Extender Box 12

5.4 Electrical connection of Pulse Transmitter 12

5.1 Connection of temperature sensors 12

5.2 Connection of ULTRAFLOW® 12

5.5 Connection of other flow sensors 13

5.7 Internal communication 13

5.6 Connection of power supply 13

6 Testing of function 14

7 Information code 15

8 Communication Modules 16

8.1 Module overview 16

8.2 Pulse inputs 16

8.3 Pulse outputs 17

8.4 Data + pulse inputs, type HC-003-10 17

8.5 Data + pulse outputs, type HC-003-11 17

8.6 M-Bus + pulse inputs, type HC-003-20 18

8.7 M-Bus + pulse outputs, type HC-003-21 18

8.8 M-Bus + Thermal Disconnect, type HC-003-22 18

8.9 Wireless M-Bus + pulse inputs, type HC-003-30 19

8.10 Wireless M-Bus + pulse outputs, type HC-003-31 19

8.11 Analog outputs, type HC-003-40 19

8.12 LON FT-X3 + 2 pulse inputs, type HC-003-60 20

8.13 BACnet MS/TP + 2 pulse inputs, type HC-003-66 20

8.14 Modbus + pulse inputs, type HC-003-67 20

9 Set-up via front keys 21