Boxi II – Manual 1. Introduction

1 Introduction

First of all, we would like to thank you for purchasing our device.

This manual describes the technical description of the unit, installation and

operation. There are two hardware versions of Boxi device: Boxi and BoxiII.

This manual is for Boxi II version only. Boxi II units are shipped from May

2021.

1.1 General Description

Boxi is an electrical actuator control box. It allows pilot to control airborne

electrical actuators such as pitch and roll trims, landing gear actuators, flaps,

radio transmission, electronic throttle, etc. with Joyu flight control stick.

Other devices communicate with Boxi device via CAN bus. Boxi listens to

incomming CAN messages and based on their content, controlls its outputs.

Boxi has implemented several fail-safe mechanisms which sets the outputs in

predefined state in case of disrupted CAN communication. Boxi also monitors

the health of all outputs and is able to monitor two external analog inputs.

Due to safety reasons the electronics has implemented two isolated CAN buses:

main CAN bus and Joyu CAN bus. This feature also allows Boxi to be used

as a communication switch between two isolated CAN buses.

Boxi unit is powered over separated power connector. The electronics will

operate correctly even if the main CAN bus is not active or is in error state.

One of the key advantages is the ease of installation. Boxi shall be installed close

to power actuators. This reduces system weight and electrical interferences.

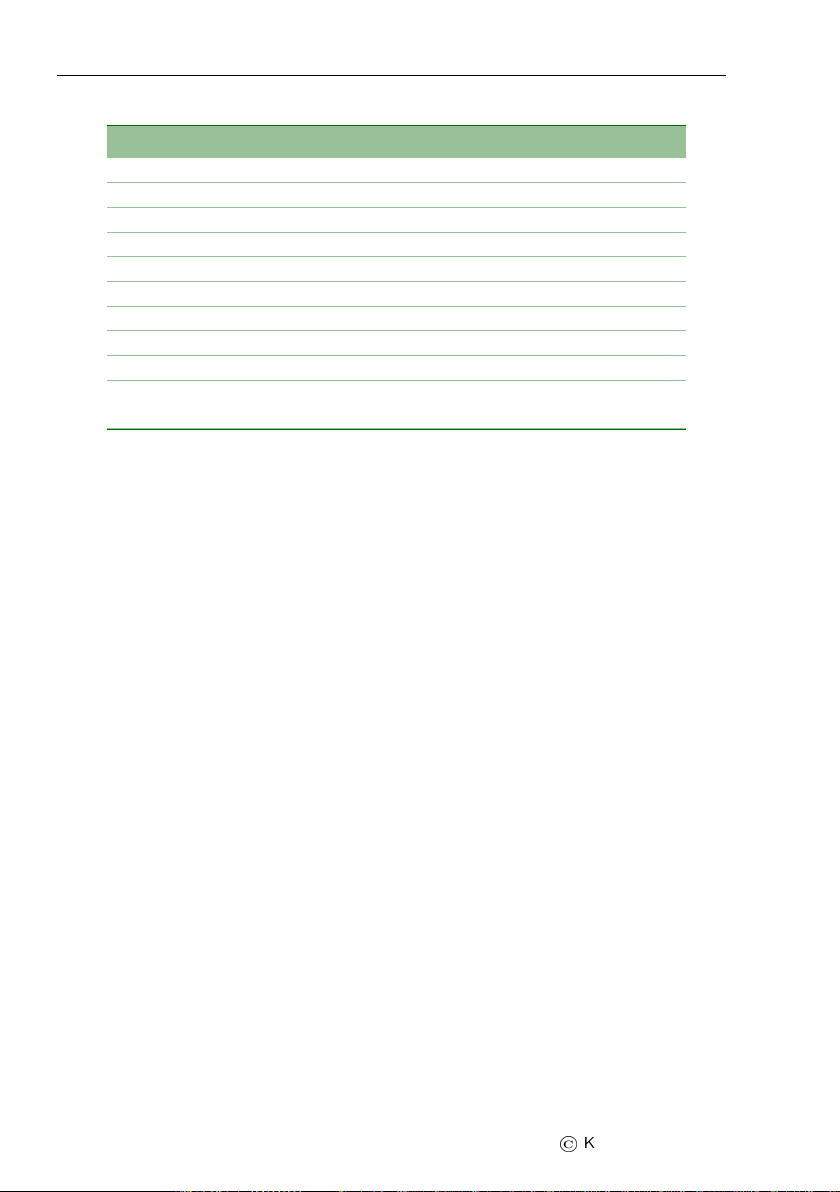

1.2 Technical Specification

Table 1 shows some basic technical specification of Boxi.

2 Functional Description

Boxi electronics consists of: CAN interface, control logic, power output and

analog input. Boxi electronic is isolated from the main CAN bus to eliminate

stray currents between power electronics and main communication bus.

1Electronics only, without outputs.

6

©

Kanardia 2006-2021