Page 2 Edition I 03.12.2012

Table of contents

1.

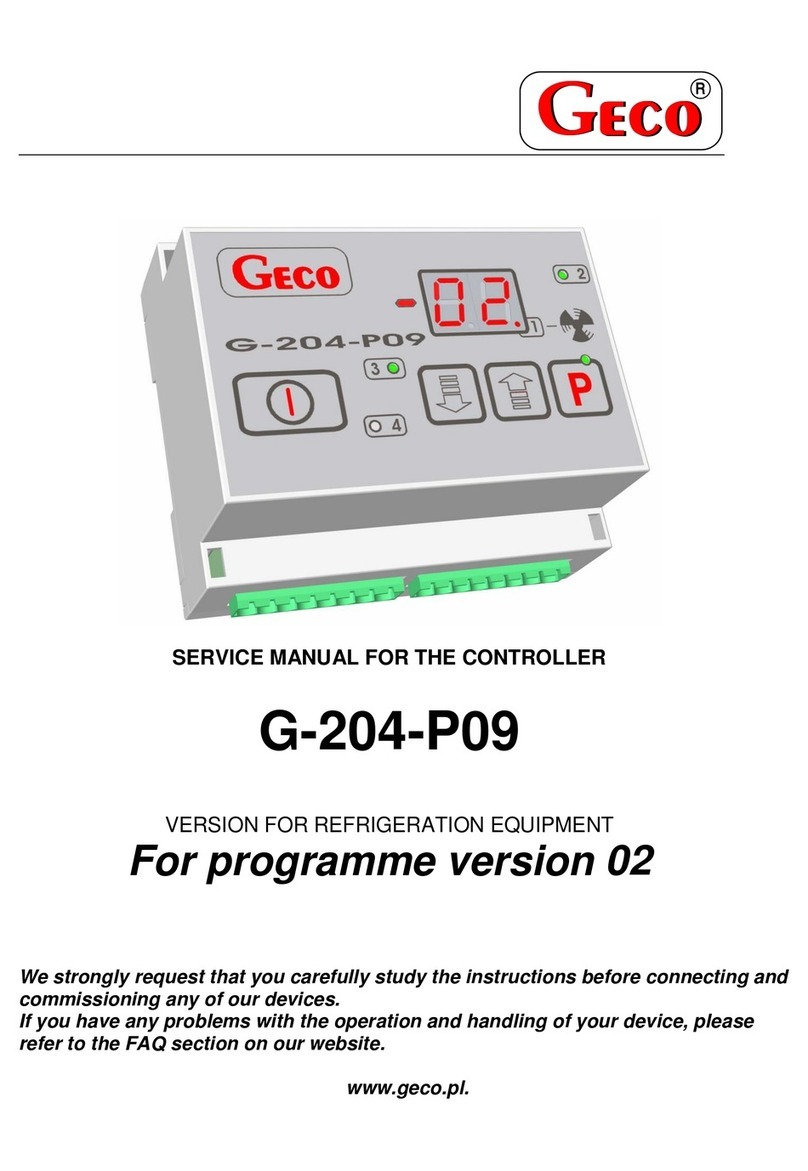

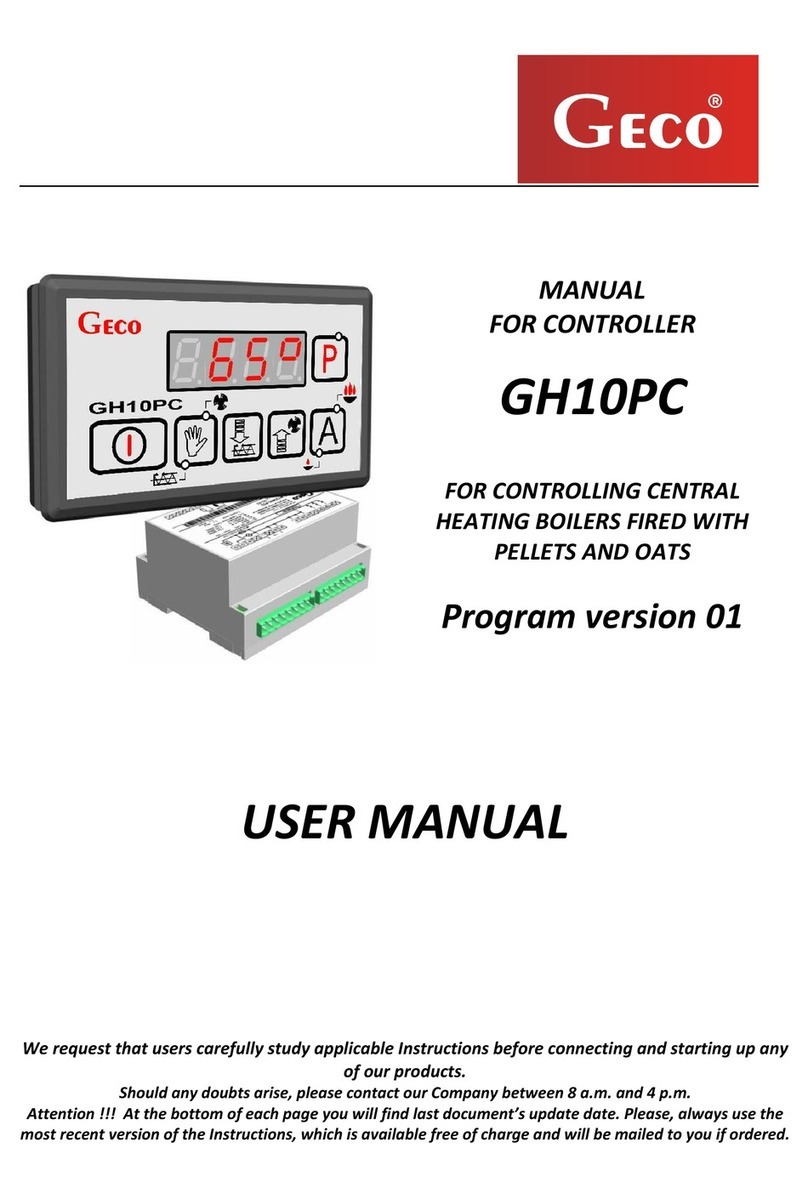

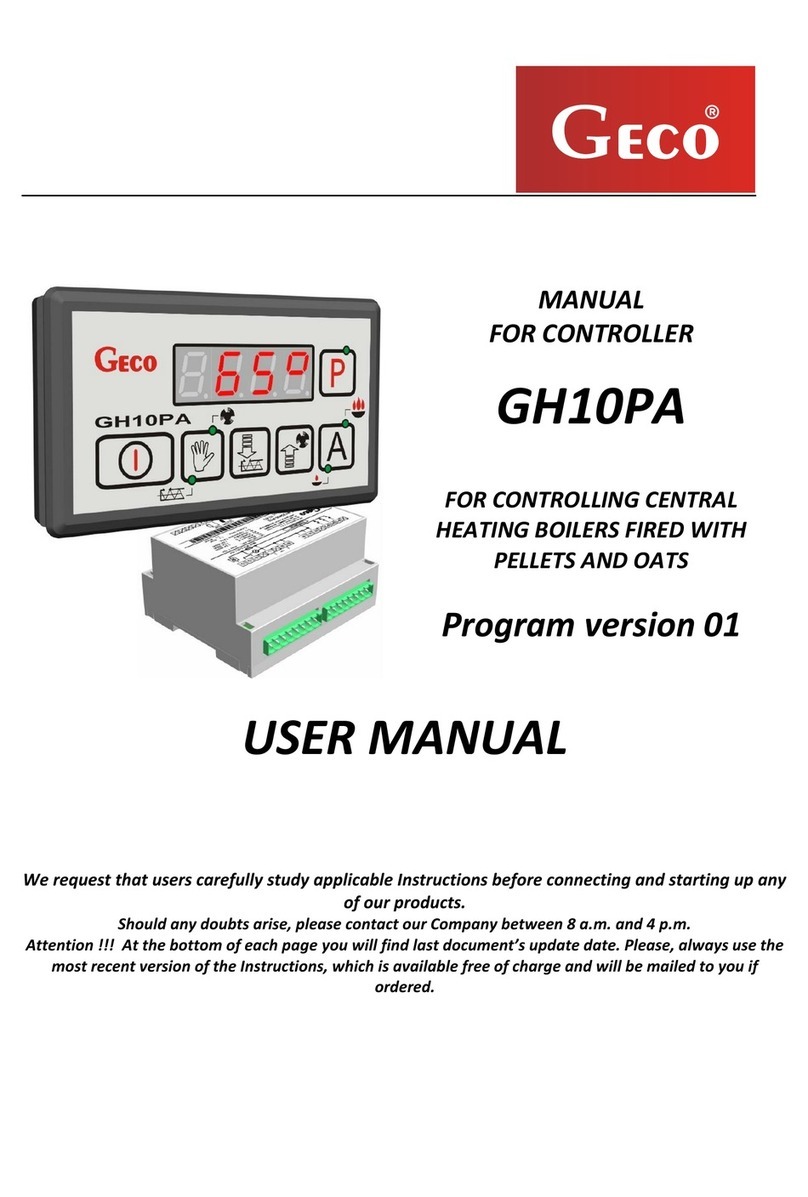

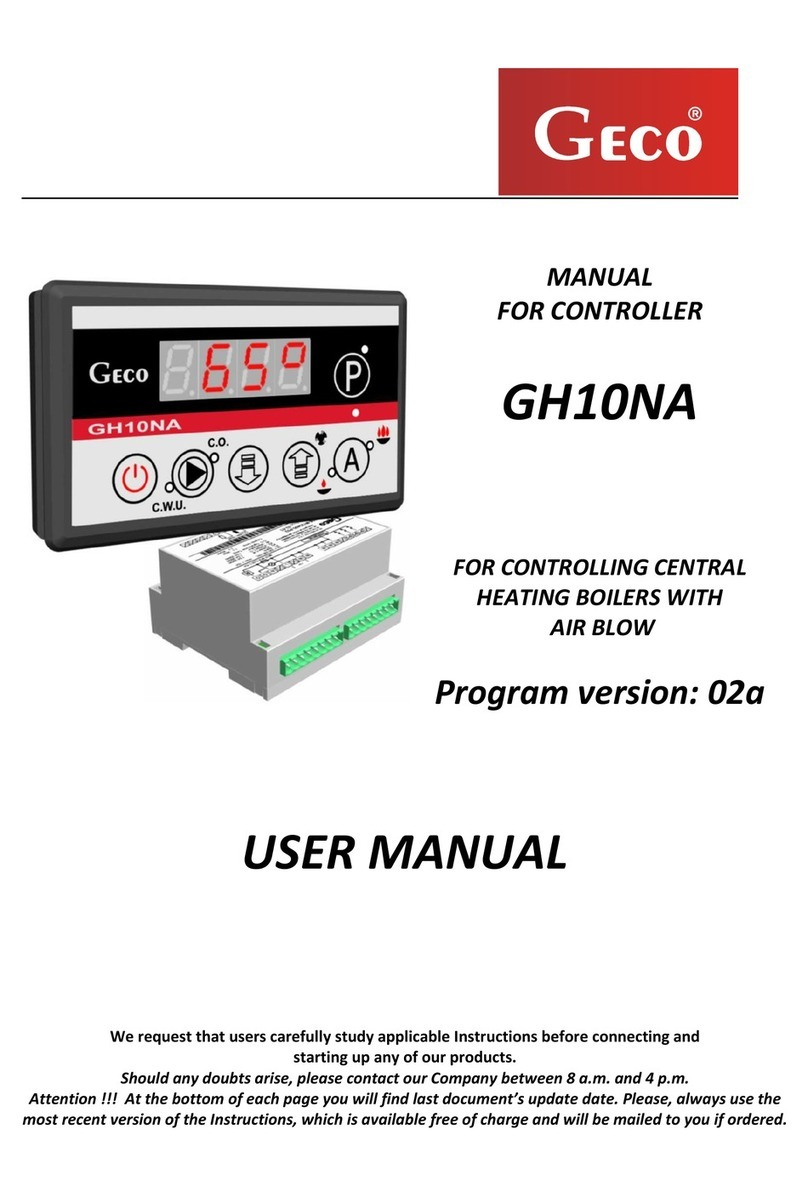

DE CRIPTION OF CONTROLLER.......................................................................................................................3

2.

TECHNICAL DETAIL . .........................................................................................................................................4

3.

REQUIREMENT FOR ELECTRICAL IN TALLATION......................................................................................4

4.

GRAPHIC AND TEXT DE CRIPTION OF CONTROLLER IN TALLATION .....................................................5

5.

CONTROLLER MODE .........................................................................................................................................6

5.1.

TANDBY MODE

..............................................................................................................................................7

5.2.

A

UTOMATIC MODE

..........................................................................................................................................7

5.3.

M

ANUAL MODE

...............................................................................................................................................8

5.4.

A

LARM MODE

.................................................................................................................................................8

6.

OPERATING THE CONTROLLER .......................................................................................................................8

6.1.

C

ONTROLLER FA CIA PANEL

............................................................................................................................9

6.2.

O

VERVIEW OF TEMPERATURE ETTING

........................................................................................................10

6.3.

M

ANUAL MODE

–

CONNECTED DEVICE

..........................................................................................................10

6.4.

E

DIT U ER PARAMETER

...............................................................................................................................11

7.

DE CRIPTION OF ADDITIONAL FUNCTION ................................................................................................12

7.1.

DHW

PRIORITY

...........................................................................................................................................12

7.2.

UMMER MODE

.............................................................................................................................................12

7.3.

A

NTI

-

LEGIONELLA FUNCTION

........................................................................................................................12

8.

OPERATING Y TEM IN TALLATION ..........................................................................................................14

8.1

H

EATING IN TALLATION NR

1.......................................................................................................................14

8.2

H

EATING IN TALLATION NR

2.......................................................................................................................15

8.3

H

EATING IN TALLATION NR

3.......................................................................................................................16

9.

ALARM . .............................................................................................................................................................17

10.

TEMPERATURE LIMITER ( TB).................................................................................................................17

11.

POWER FAILURE. .........................................................................................................................................18

12.

ROOM THERMO TAT. .................................................................................................................................18

12.1

GA01HD

ROOM PANEL

................................................................................................................................18

12.2

R

OOM THERMO TAT

.....................................................................................................................................19

13.

INFORMATION REGARDING THE LABELING AND DI PO AL OF WA TE ELECTRICAL AND

ELECTRONIC EQUIPMENT.........................................................................................................................................19