Page 2 SB-6-105-J

INSTALLATION

1. Install regulator as close as possible to the device being

serviced. Regulator can be installed at any angle.

2. In systems with a cyclic demand, install regulator upstream

of cycling control valves.

3. Air line piping should be same size as regulator ports.

4. Air flow must be in same direction as arrow on bottom of

regulator body.

OPERATION

1. Before turning on system air pressure, turn adjusting knob full

counterclockwise. This will close regulator to produce zero

air pressure. The knob is locked in position when pushed

downward towards the regulator body.

2. Turn on system air pressure.

3. Turn regulator adjusting knob clockwise until desired outlet

pressure is reached.

4. To avoid minor readjustment after making a change in pres-

sure setting, always approach the desired pressure from a

lower pressure. When reducing from a higher to a lower

setting, first reduce to some pressure less than that desired,

then bring up to the desired point. Lock the pressure setting

by pushing the knob downward.

PREVENTATIVE MAINTENANCE

Risk of injury from pressurized components. Turn off

inlet air pressure and bleed off remaining pressure

before disassembly.

1. Turn regulator knob counterclockwise until it stops.

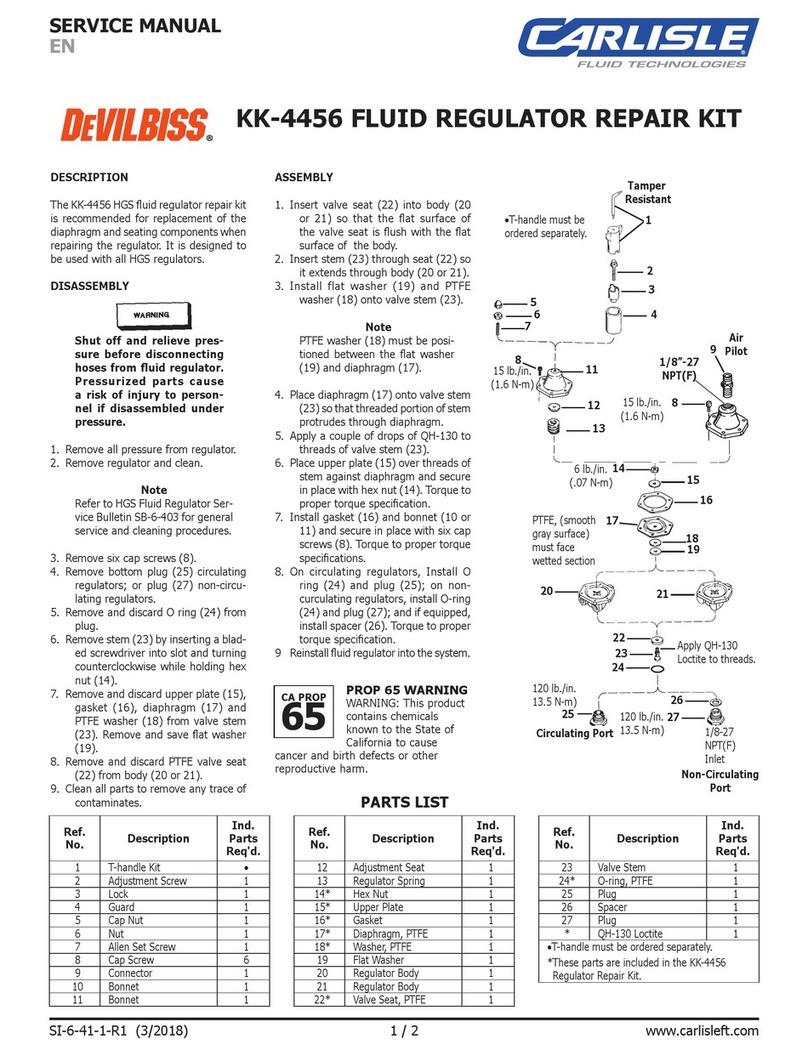

2. Unscrew the bonnet from the regulator body, remove adjusting

screw and nut, then the regulating spring (4), slip ring (5)

and diaphragm (6). Using a screwdriver, unscrew the

valve seat (7) and o-ring (8). Then remove valve (9) and valve

spring (10).

Ref.

No. Description Qty.

1 Bonnet

2 Adjusting Screw

3 Nut

4 Regulating Spring

*5 Slip Ring 1

*6 Diaphragm, Teflon 1

Protected

*7 Valve Seat 1

*8 O-ring 1

*9 Valve, Teflon 1

*10 Valve Spring 1

11 Regulator Body 1

* Included in KK-4887-2 Regulator Kit.

1

2

3

4

5

6

9

11

10

CLEANING

Do not submerge regulator in spray gun solvents or use

solvents to clean regulator parts. Damage may occur to

gauge or regulator components.

1. Clean parts using warm water and soap.

2. Inspect all parts and replace any damaged ones.

Reassembly:

1. At reassembly, apply a small amount of lubricant SSL-10 gun

lube to adjusting screw threads inside bonnet.

2. Torque valve seat (7) to 4-6 in./lbs. (do not overtighten).

Torque bonnet to 50-60 in./lbs.

7

8

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Sales and Service: www.devilbiss.com

DeVilbiss

DeVilbiss has authorized distributors throughout the world. For technical

assistance or the distributor nearest you, see listing below.

U.S.A./Canada Customer Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-800-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-888-246-5732

DeVilbiss Automotive Refinishing

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S.A./Canada Customer Service Office:

11360 S. Airfield Road, Swanton, OH 43558

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

9/11 ©2011 DeVilbiss All rights reserved. Printed in U.S.A.